Preparation method of catalyst for hydroxypivalaldehyde liquid phase hydrogenation preparation of neopentylene glycol

A technology of hydroxypivalaldehyde and neopentyl glycol, applied in the field of catalysis, can solve the problems of unmentioned catalyst strength and mechanical stability, unmentioned catalyst strength and filling, threatening the stable operation of industrial devices, etc. The effect of crack generation, good liquid resistance, low breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

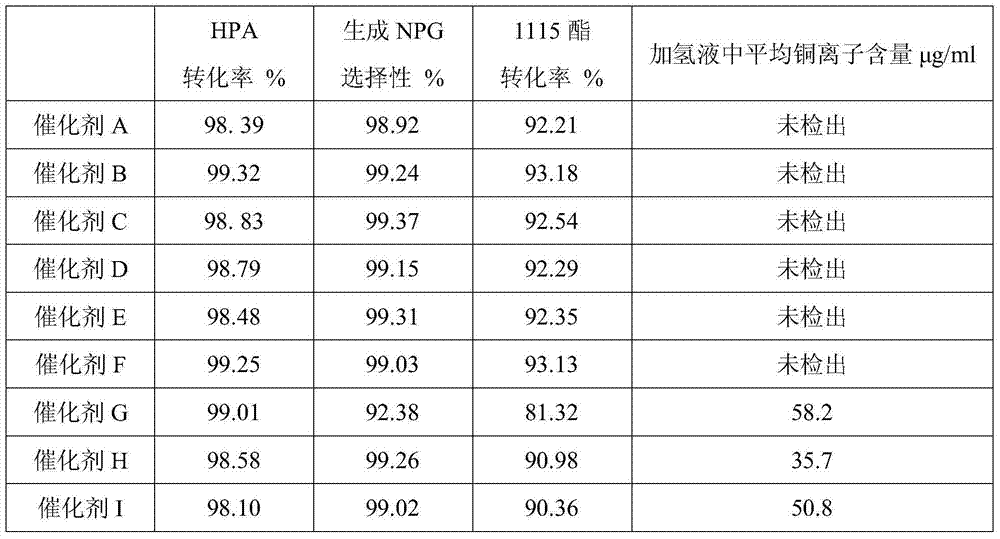

Examples

Embodiment 1

[0040] Add 3kg of water into the reaction kettle, and add 19.5g of nano-titanium oxide with a particle size of 20-40nm, and stir evenly. 384.1g copper nitrate, 619.3g aluminum nitrate, 90.8g zinc nitrate, 2.92g stannous chloride, 51.4g calcium nitrate were dissolved in 2.7kg water to make mixed salt solution, and sodium carbonate was dissolved in water to make 20wt% carbonic acid Sodium solution, respectively, the two solutions were heated to 60 ℃. The method of co-precipitation was adopted, and the two solutions were dropped into the reactor at the same time, and the temperature in the reactor was controlled to be 60° C., the pH of the system was 6.0, and the reaction time was 1 h during the precipitation process. After adding the mixed brine solution, use sodium carbonate solution to adjust the pH of the system to 7.5, and age at 70°C for 3h, then filter, wash and dry the filter cake at 110°C for 12h, and roast at 350°C for 3h to break Then press it into a 5*5mm cylinder (d...

Embodiment 2

[0044] Add 3kg of water into the reaction kettle, and add 11.7g of nano-titanium oxide with a particle size of 20-30nm, and stir evenly. 530.4g of copper nitrate, 358.6g of aluminum nitrate, 90.8g of zinc nitrate, 71.8g of magnesium nitrate, and 11.7g of stannous chloride were dissolved in 2.5kg of water to make a mixed salt solution, and sodium carbonate was dissolved in water to make 20wt% carbonic acid Sodium solution, the two solutions were heated to 80 ℃. The method of co-precipitation is adopted, and the two solutions are dropped into the reaction kettle at the same time, and the temperature in the kettle is controlled to be 80° C., the pH of the system is 5.5, and the reaction time is 1.5 hours during the precipitation process. After adding the mixed brine solution, adjust the pH of the system to 7.0 with sodium carbonate solution, and continue to age at 70°C for 3h, then filter, wash and dry the filter cake at 110°C for 12h, and roast at 500°C for 3h. The calcined cat...

Embodiment 3

[0047] Add 3 kg of water into the reaction kettle, and add 15.6 g of nano-zirconia with a particle size of 20-30 nm, and stir evenly. Dissolve 439.0g copper nitrate, 358.6g aluminum nitrate, 181.6g zinc nitrate, 33.2g barium nitrate, 5.84g tin protochloride in 2.5kg water to configure mixed brine solution, dissolve sodium carbonate in water to make 20wt% sodium carbonate solution, the two solutions were heated to 60 ° C. The method of co-precipitation was adopted, and the two solutions were dropped into the reactor at the same time, and the temperature in the reactor was controlled to be 60° C., the pH of the system was 5.5, and the reaction time was 2 hours during the precipitation process. After adding the mixed brine solution, adjust the pH of the system to 7.7 with sodium carbonate solution, and continue to age at 80°C for 3h, then filter, wash and dry the filter cake at 110°C for 12h, and roast at 650°C for 3h. The calcined catalyst was crushed and pressed into a 5*5mm c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com