Environment-friendly modified ASA (Acrylonitrile Styrene Acrylate) profiled bar base station antenna outer cover and preparation method thereof

An environment-friendly, base station antenna technology, applied in the field of profiled cover and its preparation, can solve problems such as lack of long-term resistance to ultraviolet radiation, continuous production of twin-screw extruders, and no thermal conductivity of materials involved. , to achieve the effect of excellent UV resistance, low thermal conductivity and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

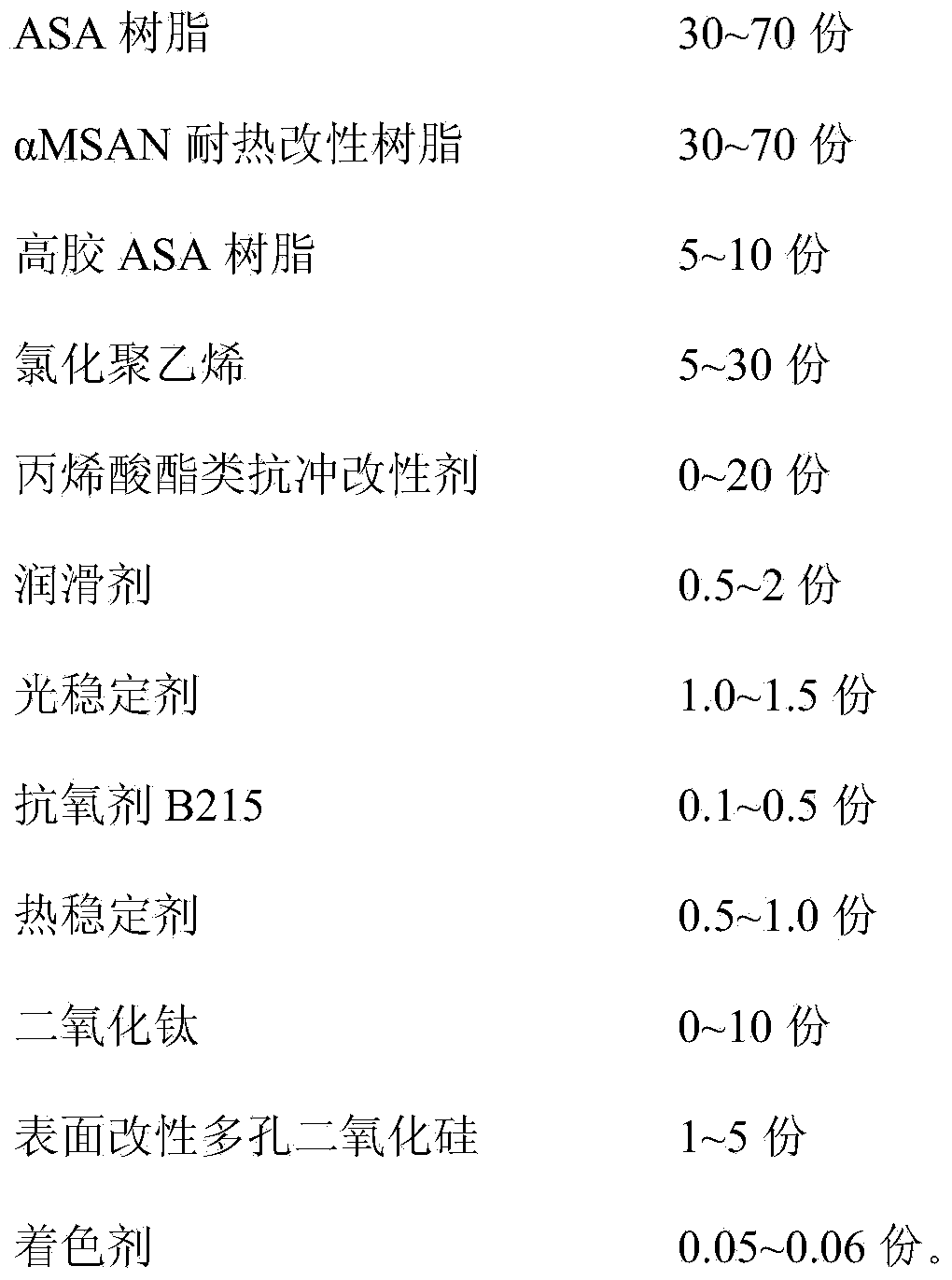

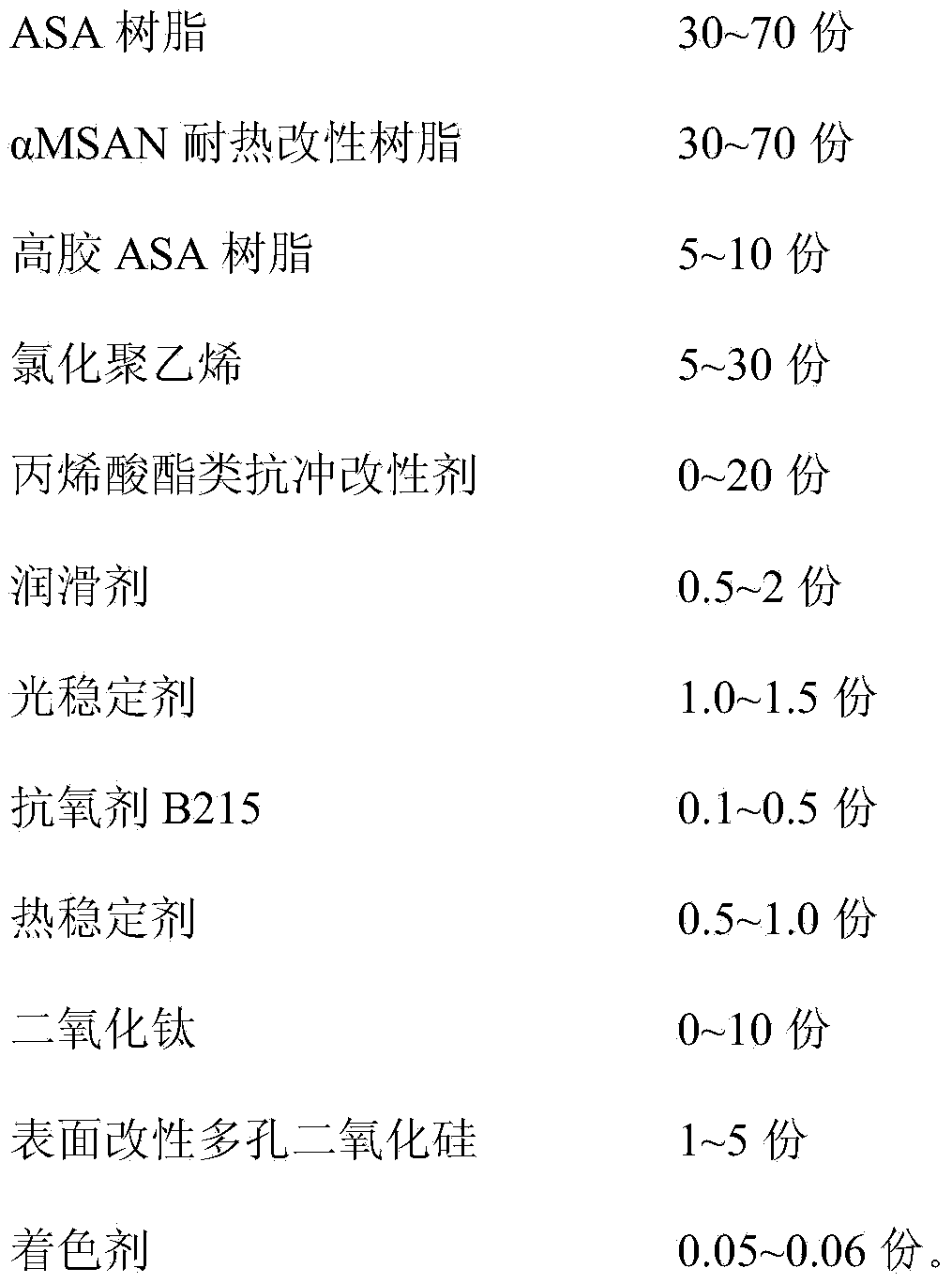

Method used

Image

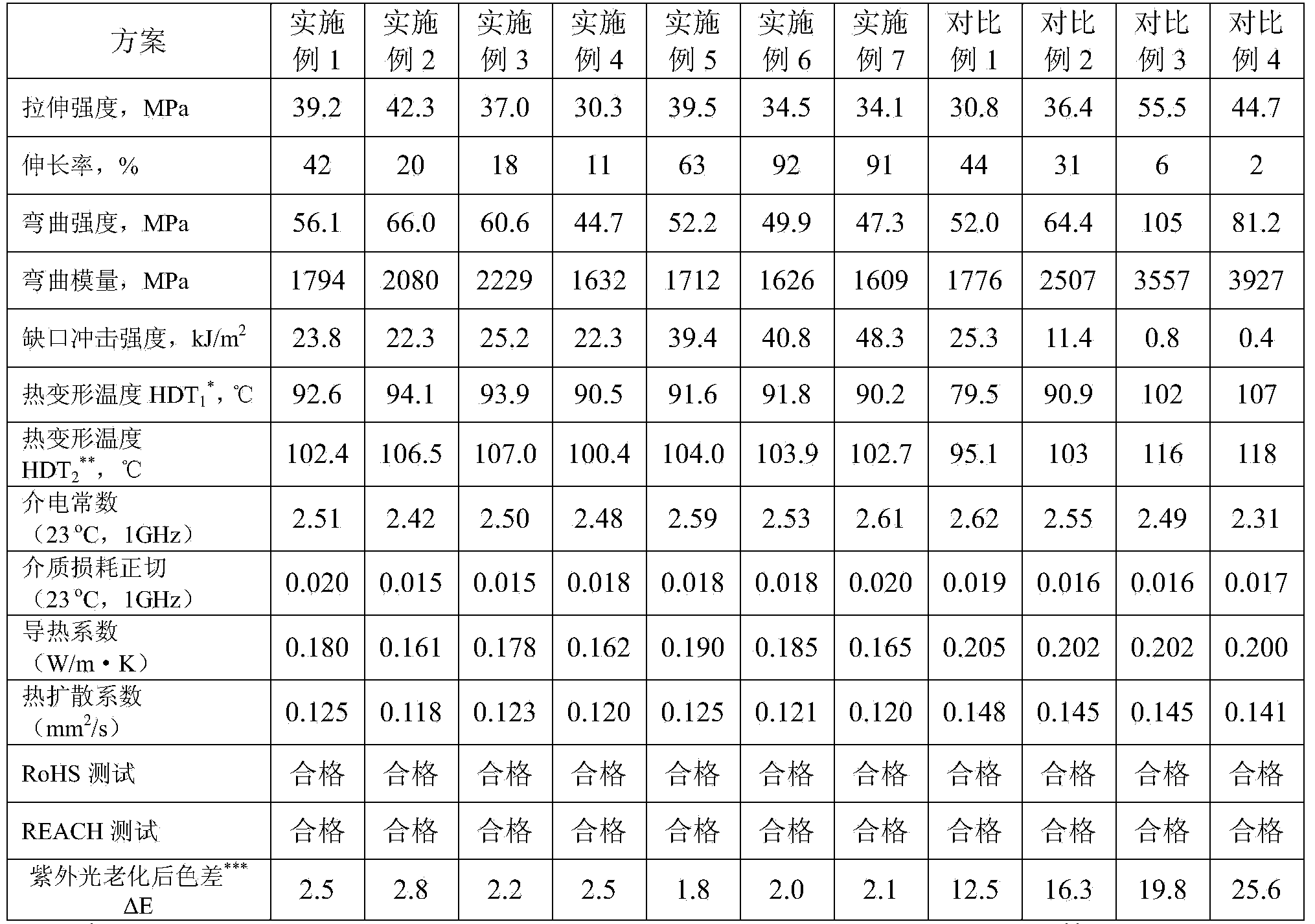

Examples

Embodiment 1

[0032] Raw material formula: ASA resin (220°C×10kg melt flow rate=2.5g / 10min) 70, αMSAN heat-resistant modified resin (mass ratio α-methylstyrene / acrylonitrile=75 / 25, 220°C×10kg melt Volume flow rate 3.0g / 10min) 30, chlorinated polyethylene 15, high glue ASA resin (PBA content 60wt%) 5, oxidized polyethylene wax 1.5, ultraviolet light absorber UV3261.0, hindered amine light stabilizer C9440. 5. Antioxidant B2150.25, mercaptan organotin 0.6, surface modified porous silica 2, coloring agent 0.05.

[0033] Preparation Process:

[0034] ①Firstly, raw materials such as chlorinated polyethylene, mercaptan organotin, oxidized polyethylene wax, antioxidant B215, ultraviolet light absorber UV326, hindered amine light stabilizer C944 are processed in a vertical plastic mixer at 20°C Pre-mixing, during the stirring process, turn forward for 2 minutes, reverse for 2 minutes, and mix for 8 minutes in turn.

[0035] ② Add premixed chlorinated polyethylene premix, ASA resin, αMSAN heat-res...

Embodiment 2

[0039] Raw material formula: ASA resin (220°C×10kg melt flow rate=3.3g / 10min) 30, αMSAN heat-resistant modified resin (mass ratio α-methylstyrene / acrylonitrile=70 / 30, 220°C×10kg melt Volume flow rate 3.6g / 10min) 30, chlorinated polyethylene 10, high glue ASA resin (PBA content 70wt%) 10, oxidized polyethylene wax 0.5, magnesium stearate 0.5, ultraviolet light absorber UV3261.0, hindered amine Light stabilizer C9440.5, antioxidant B2150.25, mercaptan organotin 0.5, surface modified porous silica 5, colorant 0.05.

[0040] Preparation Process:

[0041] ① Firstly, raw materials such as chlorinated polyethylene, mercaptan organotin, oxidized polyethylene wax, magnesium stearate, antioxidant B215, ultraviolet light absorber UV326, hindered amine light stabilizer C944, etc. Type plastic mixer for pre-mixing, during the stirring process, turn forward for 2 minutes, reverse for 2 minutes, and mix for 4 minutes in turn.

[0042] ② Add premixed chlorinated polyethylene premix, ASA resin...

Embodiment 3

[0046] Raw material formula: ASA resin (220°C×10kg melt flow rate=3.0g / 10min) 35, αMSAN heat-resistant modified resin (mass ratio α-methylstyrene / acrylonitrile=70 / 30, 220°C×10kg melt Volume flow rate 3.6g / 10min) 65, chlorinated polyethylene 15, high glue ASA resin (PBA content 65wt%) 5, acrylate impact modifier 5, ethylene bis stearic acid amide 1.0, stearic acid Barium 0.5, calcium stearate 0.5, UV absorber UV3260.7, hindered amine light stabilizer C9440.8, rutile titanium dioxide 3, antioxidant B2150.25, mercaptan organotin 0.7, surface modified porous di Silicon oxide 3, colorant 0.06.

[0047] Preparation Process:

[0048] ① First, chlorinated polyethylene, mercaptan organotin, ethylene bisstearic acid amide, barium stearate, calcium stearate, antioxidant B215, ultraviolet light absorber UV326, hindered amine light stabilizer C944, etc. The raw materials were pre-mixed in a vertical plastic mixer at 30°C. During the stirring process, it was rotated forward for 2 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com