Single-sided or double-sided optical hardened polyester film and preparation method thereof

A polyester film, single-sided technology, applied in the field of touch display, can solve the problems of complex production and processing of optically hardened polyester film, low light transmittance, environmental impact, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

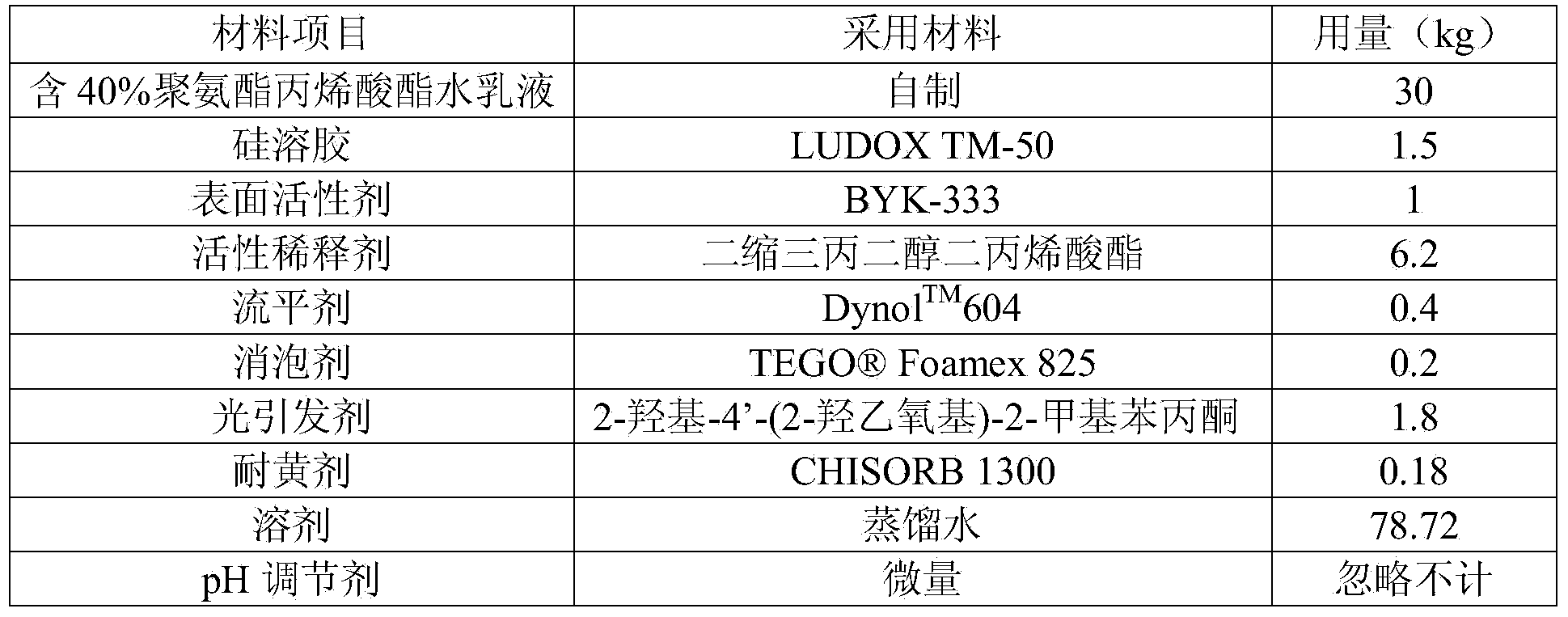

[0039] Preparation of Part 1 Hardening Resin Coating Solution

[0040] Basic process: In a preparation container that can be weighed, add 25 to 75 parts by weight of an aqueous emulsion containing 40% polyurethane acrylate under stirring, and after stirring for 30 minutes, add a very small amount of pH regulator N,N-dimethyl Base ethanolamine, make the pH=9.5 that contains 40% urethane acrylate aqueous emulsion, add 1~8 weight part nano-silica sol, 0.5~2 weight part surfactant, 0.1~1 weight part leveling agent, 0.1~ 0.5 parts by weight of defoamer, 1 to 10 parts by weight of photoinitiator, 0.1 to 1.2 parts by weight of anti-yellowing agent, and finally add 5 to 15 parts by weight of reactive diluent, and then add deionized water until the total material reaches 120 parts by weight, and again A very small amount of N,N-dimethylethanolamine was added dropwise to adjust the pH to 9.5, and then stirred for 30 minutes to obtain a hardened resin coating solution with a viscosity of...

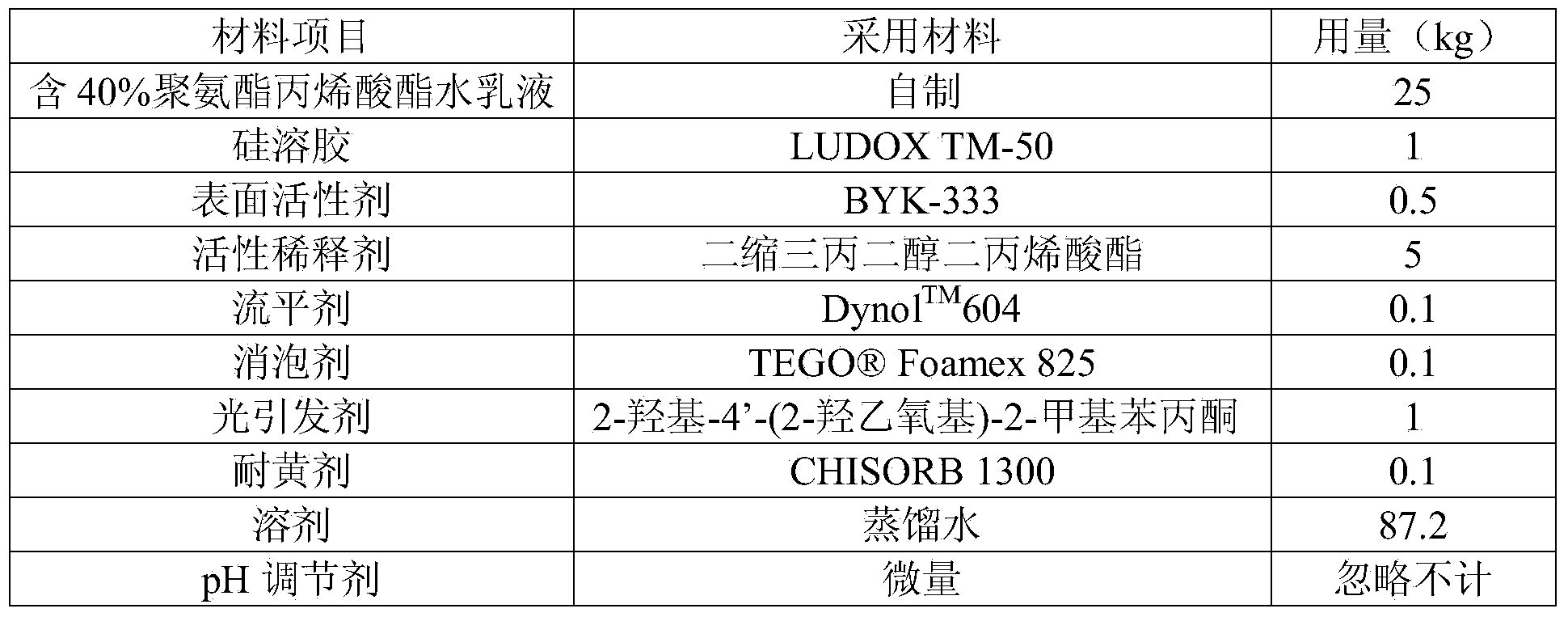

Embodiment 1

[0042] Formula 1 of the hardened resin coating solution of the present invention (the 1# hardened resin coating solution has a viscosity of 48mPa·s at 25°C):

[0043]

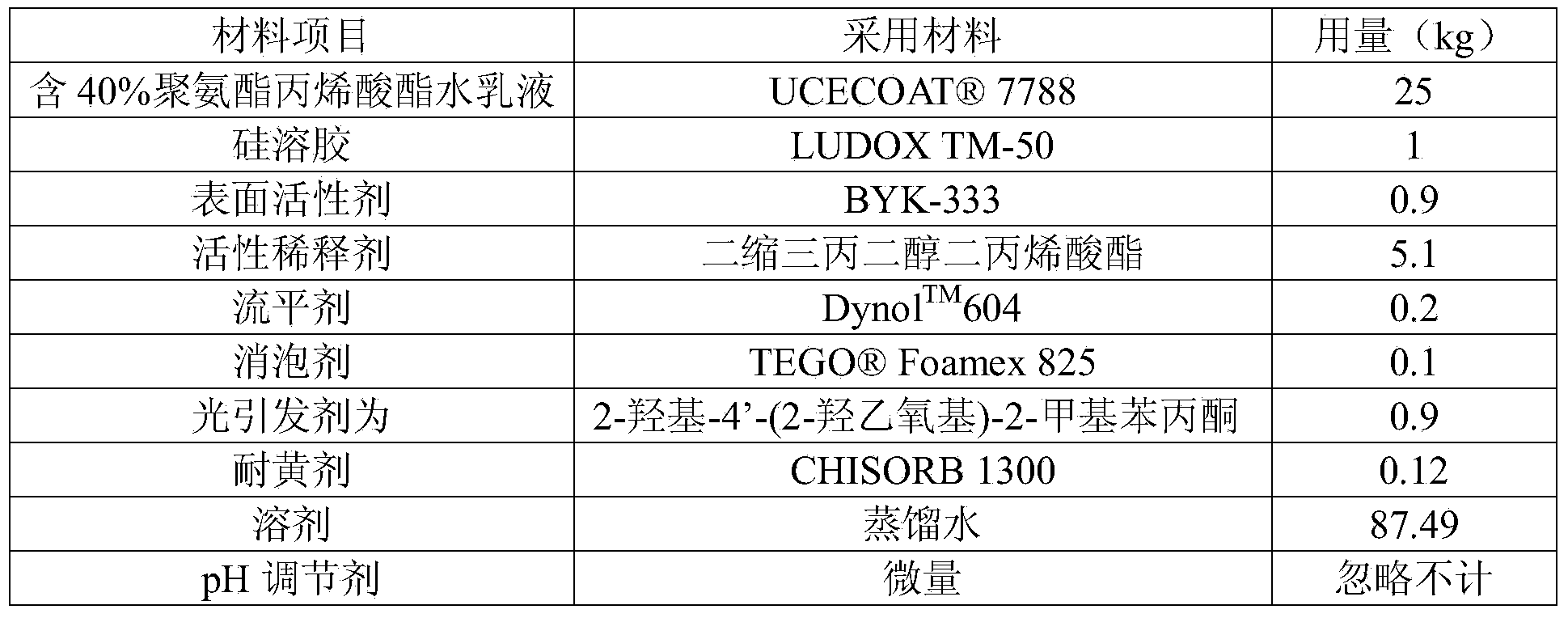

Embodiment 2

[0045] Formula 2 of the hardened resin coating solution of the present invention (the 2# hardened resin coating solution has a viscosity of 51 mPa·s at 25°C):

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com