Polyurethane thermoplastic bone fixing plate and preparation method thereof

A thermoplastic and polyurethane technology, applied in medical science, surgery, etc., can solve the problems of prone to skin allergies, medical gypsum boards and gypsum bandages, etc., improve daily life, is conducive to popularization and application, and has a simple preparation method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

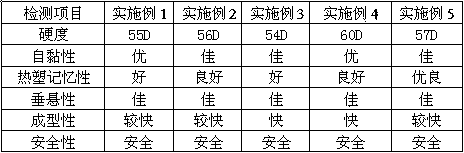

Examples

Embodiment 1

[0047] The preparation method of the polyurethane thermoplastic bone fixation plate of the present embodiment comprises the following preparation steps:

[0048] a, 90 parts by weight of polyester polyol, 25 parts of 4,4-MDI, 25 parts of 2,4-MDI, 2 parts of ethylene glycol, 1 part of propylene glycol, 2 parts of 1, Add 3-butanediol, 3 parts of 1,4-butanediol, and 1 part of 2-methyl-1,3-propanediol into the twin-screw extruder, and react at a temperature of 220°C to extrude Granulating to obtain polyurethane granules;

[0049] Among them, the polyester polyol is made of a mixture of succinic acid, adipic acid and ethylene glycol, 1,3-butanediol, and 1,4-butanediol in a molar ratio of 1.03:1 through a vacuum melting method. It is formed by dealcoholization and dehydration polycondensation. In the vacuum melting method, the above ratio of raw materials is firstly subjected to the initial esterification reaction at 120°C for 2 hours, then the temperature is raised to 180°C, and t...

Embodiment 2

[0053] The preparation method of the polyurethane thermoplastic bone fixation plate of the present embodiment comprises the following preparation steps:

[0054] a, be the polyester polyol of 95 parts by weight, the MDI-50 of 20 parts, the H of 25 parts 12 MDI, 2 parts of hexanediol, 2 parts of 3-methyl-1,5-pentanediol, 2 parts of 1,4-cyclohexanedimethanol, 2 parts of hydroquinone bis(2-hydroxyethyl Base) ether into the twin-screw extruder, and react at a temperature of 250 ° C, extrude and granulate to obtain polyurethane granules;

[0055]Among them, the polyester polyol is a mixture of azelaic acid, sebacic acid and diethylene glycol, neopentyl glycol, 2-methyl-1,3-propanediol according to the molar ratio of 1.14:1 through the vacuum melting method It is formed by dealcoholization and dehydration polycondensation. Firstly, the above ratio of raw materials is subjected to initial esterification reaction at 130°C for 1.75h, then the temperature is raised to 200°C, and the hy...

Embodiment 3

[0059] The preparation method of the polyurethane thermoplastic bone fixation plate of the present embodiment comprises the following preparation steps:

[0060] A, be the polyester polyol of 100 parts by weight, the HDI of 15 parts, the XDI of 15 parts, the IPDI of 10 parts, the 4-hydroxyethyloxyethyl-1-hydroxyethyl phenylene diether of 3 parts, 2 parts of resorcinol-bis(β-hydroxyethyl) ether and 1 part of 3-hydroxyethyloxyethyl-1-hydroxyethyl phenylene ether were added to the twin-screw extruder, and heated at 230°C React at a certain temperature, extrude and granulate to obtain polyurethane granules;

[0061] Among them, the polyester polyol is a mixture of sebacic acid, terephthalic acid, phthalic anhydride, hexanediol, 3-methyl 1,5-pentanediol, 1,4-cyclohexanedimethanol, and glycerin According to the molar ratio of 1.25:1, it is produced through dealcoholization and dehydration polycondensation by the vacuum melting method. In the vacuum melting method, the raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com