Flame-retardant brominated butyl rubber material and preparation method thereof

A technology of brominated butyl rubber and rubber compound, which is applied in the field of rubber materials, can solve the problems of poor wear resistance, low mechanical properties, corrosion resistance, ozone resistance and ultraviolet resistance, etc., and achieve good wear resistance and mechanical properties. The effect of excellent performance, mutual adhesion and improved co-crosslinking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A flame-retardant brominated butyl rubber material and a preparation method thereof, wherein the chemical composition ratio of the flame-retardant brominated butyl rubber material includes 88 parts of brominated butyl rubber, 9 parts of chlorinated polyethylene, 2 parts of stearic acid 2 parts, 2 parts of zinc chloride, 2 parts of magnesium chloride, 2 parts of anti-aging agent, 3 parts of paraffin, 74 parts of flame retardant HT, 32 parts of complexed antimony, 2 parts of sulfur and 2 parts of accelerator.

[0017] A kind of preparation method of flame retardant brominated butyl rubber material, described preparation process is carried out according to the following steps,

[0018] (1) Compound mixing: Put the prepared bromobutyl rubber compound into the open mill for mixing, control the roll temperature of the open mill to 35°C, mix for 8 minutes, add chlorinated polystyrene after wrapping the roll Vinyl, and make 2 triangular bags;

[0019] (2) Mixing and tableting:...

Embodiment 2

[0022] Embodiment 2: The rest are the same as in Example 1, except that the chemical composition ratio of the flame-retardant brominated butyl rubber material includes 90 parts of brominated butyl rubber, 10 parts of chlorinated polyethylene, 2 parts of stearic acid part, 3 parts of zinc chloride, 1 part of magnesium chloride, 2 parts of antioxidant, 2 parts of paraffin, 76 parts of flame retardant HT, 30 parts of complexed antimony, 1.5 parts of sulfur and 2.5 parts of promotor; , control the roll temperature to be 38°C, knead for 9min, and make 3 triangular bags; in the step (2), add 10 parts of Qiangwei powder, and make 4 triangular bags; in the step (3), control the parking time is 24h; in the step (4), the control vulcanization temperature is 151° C., and the control vulcanization time is 30 min.

Embodiment 3

[0023] Embodiment 3: the rest are the same as in Example 1, except that the chemical composition ratio of the flame-retardant brominated butyl rubber material includes 92 parts of brominated butyl rubber, 12 parts of chlorinated polyethylene, 1 part of stearic acid part, 2 parts of zinc chloride, 2 parts of magnesium chloride, 3 parts of antioxidant, 3 parts of paraffin, 77 parts of flame retardant HT, 30 parts of complexed antimony, 2 parts of sulfur and 3 parts of accelerator; In the described step (1) , control roll temperature is 40 ℃, mixing 10min, makes 3 triangular bags; In described step (2), adds 12 parts of zinc borates, makes 4 triangular bags; In described step (3), control parking time is 25h; in the step (4), the vulcanization temperature is controlled to be 155° C., and the vulcanization time is controlled to be 35 min.

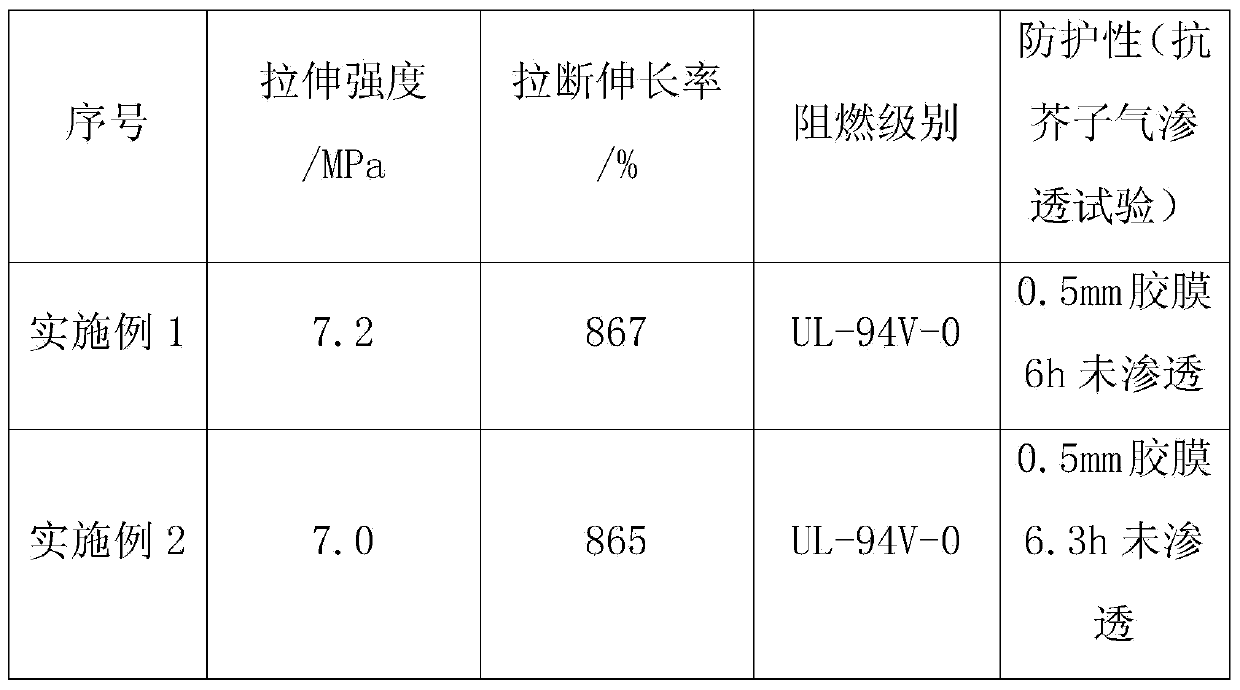

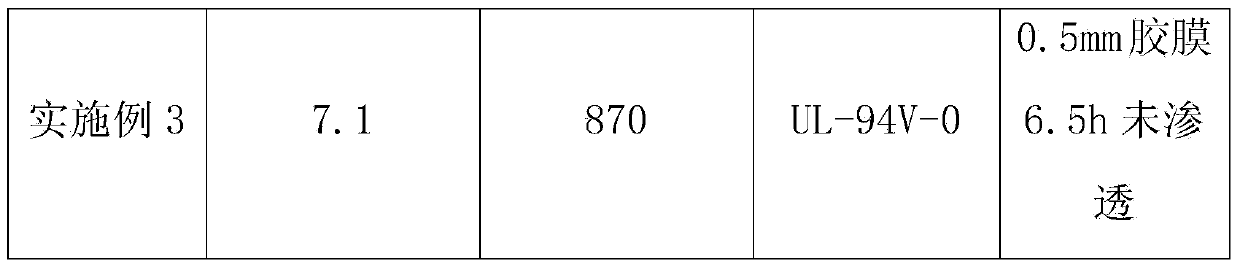

[0024] After the above process steps, the flame retardant rubber sample is taken out to be tested:

[0025]

[0026]

[0027] From the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com