Sodium alginate-chitosan double-layer edible membrane as well as preparation method and application thereof

A sodium alginate film and sodium alginate technology, applied in the field of edible films, can solve the problems of complex components, poor tensile properties, low transparency, etc., and achieve a wide range of raw material sources, good film-forming properties, and simple preparation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

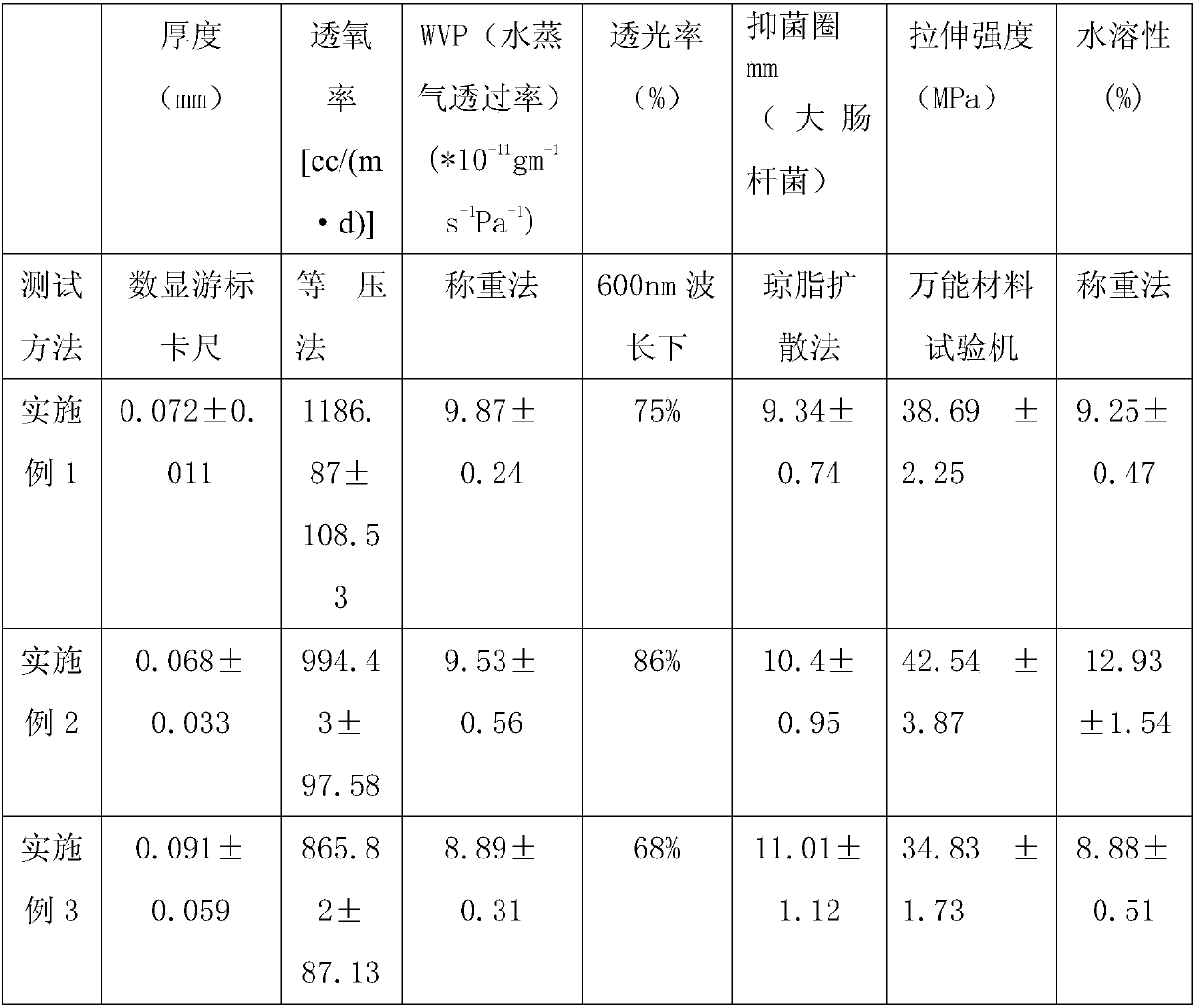

Examples

Embodiment 1

[0033] Sodium alginate-chitosan double-layer edible preservative film, the mass content of each raw material component is as follows: sodium alginate (Qingdao Mingyue Seaweed Group Co., Ltd.) 35%, chitosan (Shanghai Luan Biotechnology Co., Ltd.) 35% , glycerin 10%, Span805%, Tween80 5%, horseradish (Xi'an Weite Biotechnology Co., Ltd.) 10%.

[0034] The preparation method of sodium alginate-chitosan double layer edible preservative film, comprises the steps:

[0035] (1) Preparation of sodium alginate membrane liquid: accurately weigh 1.5g sodium alginate and dissolve it in 100ml distilled water, then add 0.2g glycerin, 0.1g Span80, 0.1g Tween80, 0.6g horseradish, stir (500 rpm ) for 5 hours to completely dissolve, mix the solution evenly to form an emulsion, then use a high-speed disperser to homogenize for 10 minutes at 10,000 rpm in a vacuum state to obtain a sodium alginate film liquid and record it as an SA liquid, and leave it for later use.

[0036] (2) Preparation of ...

Embodiment 2

[0040] Sodium alginate-chitosan double-layer edible preservative film, the mass content of each raw material component is as follows: sodium alginate (Qingdao Mingyue Seaweed Group Co., Ltd.) 23%, chitosan (Shanghai Luan Biotechnology Co., Ltd.) 46.5% , glycerin 14%, Span204.6%, Tween80 2.4%, thyme oil (International Flavors and Fragrances Co., Ltd.) 9.5%.

[0041] The preparation method of sodium alginate-chitosan double layer edible preservative film, comprises the steps:

[0042] (1) Preparation of sodium alginate membrane solution: accurately weigh 1g of sodium alginate and dissolve it in 100ml of distilled water, then add 0.3g of glycerin, 0.2g of Span20, 0.1g of Tween80, 0.4g of thyme oil, and stir with a stirrer (200 rpm min) for 6 hours to completely dissolve, mix the solution evenly to form an emulsion, and then use a high-speed disperser to homogenize at 8000rpm for 10 minutes in a vacuum state to obtain a sodium alginate film solution, which is designated as SA solu...

Embodiment 3

[0047] Sodium alginate-chitosan double-layer edible preservative film, the components and the percentage content of each component are as follows: sodium alginate (Qingdao Mingyue Seaweed Group Co., Ltd.) 23.3%, chitosan (Shanghai Luan Biotechnology Co., Ltd.) ) 30.4%, glycerin 15.4%, Span20 6.2%, Tween80 6.2%, horseradish (Xi’an Weite Biotechnology Co., Ltd.) 9.25%, thyme oil (International Flavors and Fragrances Co., Ltd.) 9.25%.

[0048] The preparation method of sodium alginate-chitosan double layer edible preservative film, comprises the steps:

[0049] (1) Preparation of sodium alginate membrane solution: Accurately weigh 1.5g sodium alginate and dissolve in 100ml distilled water, then add 0.5g glycerin, 0.4g Span20, 0.4g Tween80, 0.6g thyme oil, 0.6g horseradish with stirring Stir (800 rpm) for 8 hours to make it completely dissolve, mix the solution evenly to form an emulsion, then use a high-speed disperser to homogenize at 12000rpm for 10min in a vacuum state, and ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com