Safe and intelligent fault indicator for overhead line

A technology for fault indicators and overhead lines, which is applied to fault locations, instruments, and measuring devices. It can solve the problems of reducing the working efficiency of the magnetic circuit system of transformers, expensive equipment for ring winding machines, and damage to fault indicators. The internal water leakage structure realizes the effect of remote detection management and avoids damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

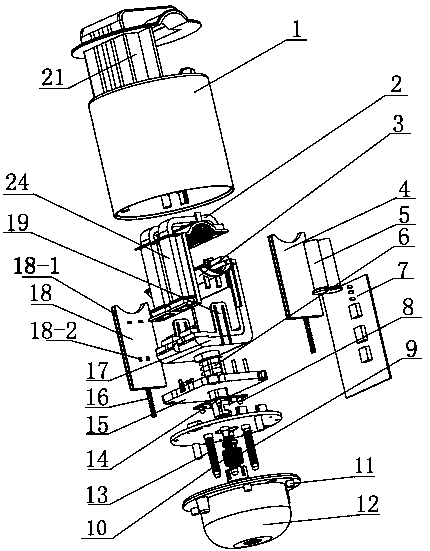

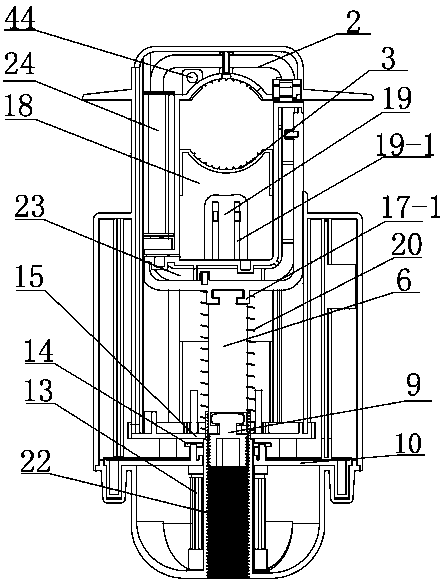

[0036] In order to more clearly illustrate the technical problems, technical solutions and beneficial effects to be solved by the patent of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

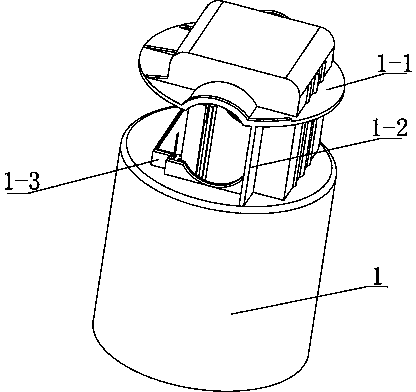

[0037]As shown in the figure, the main housing 1 of the overhead line safety intelligent fault indicator of the present invention is provided with a transformer, the lower end of the transformer is connected to a direct-push locking device, and the lower part of the direct-push locking device is provided with a dismounting device for suspension , the main housing is provided with two independent cavities, respectively the inner cavity 26 and the outer cavity 25, the upper end of the main housing is provided with a hook 21 connected with the main housing, adopting the design of the inner cavity and the outer cavity, the failure The circuit part of the indicator is separated from the locking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com