An online recovery method for tapered hole defects on the surface of crystallization rolls

A technology of tapered holes and crystal rollers, applied in the direction of pressure inorganic powder coating, etc., can solve the problems of conical hole defects, repair coating failure, bridging, disappearance, etc., to shorten the repair cycle, reduce repair costs, repair The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

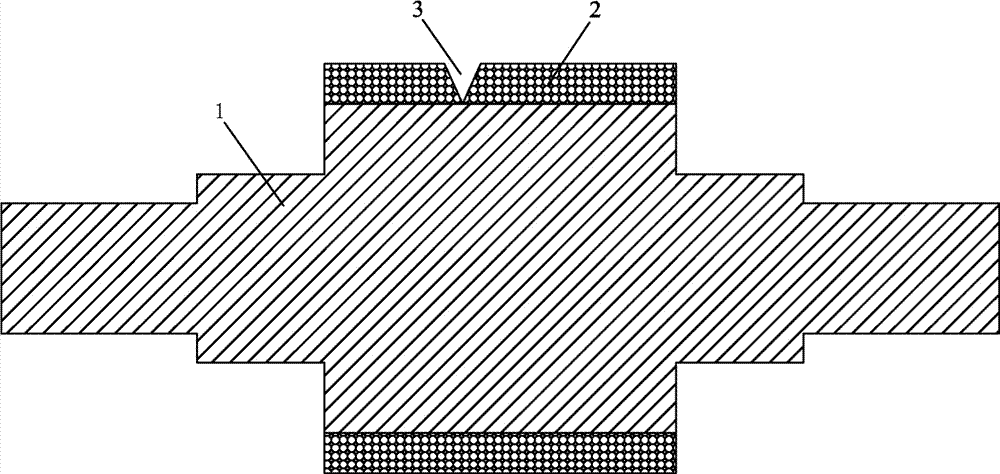

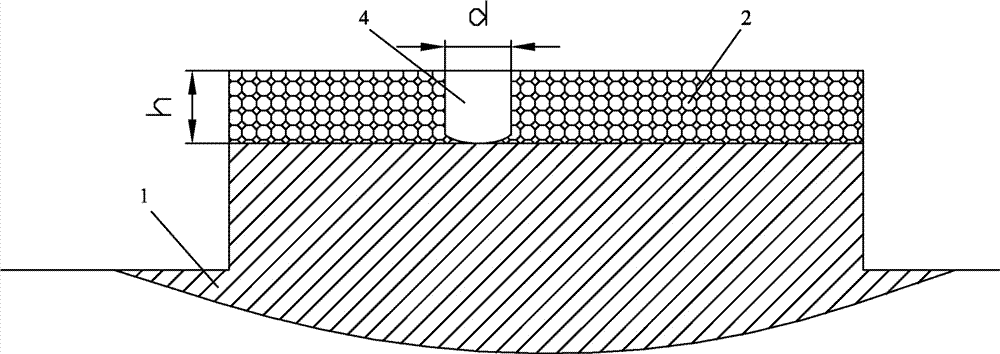

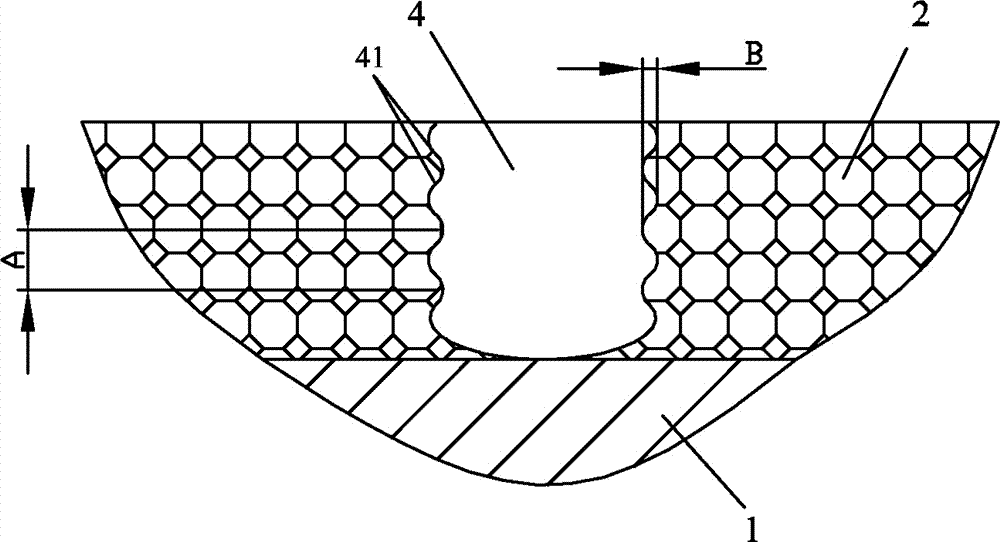

[0040] 1) The surface repair layer of the crystallization roller is CrZrCu alloy, and the diameter of the tapered hole defect is The depth is 4mm, and the method of combining drilling and grinding is used to process it into a diameter For a columnar flat-bottomed hole with a depth of h=5mm, the inner wall roughness is Ra0.6μm; use the quenched Cr12MoV steel wire tap to process the inner wall texture, and process it into a wave texture structure. The distance between adjacent textures is A=2.5mm, and the peak-to-valley difference B= 0.25mm.

[0041] 2) The utilization pressure value is 0.4MPa, the preheating temperature is 50°C, and the oil content is less than 0.8mg / m 3 , The gas-solid two-phase flow formed by compressed air with a maximum dust particle size of less than 0.6 μm and sintered α-alumina particles with a particle size of 300 μm is used for inner wall grinding. The powder feeding rate of ceramic particles is 0.2 L / h, and the impact The speed is 128m / s, and the ...

Embodiment 2

[0045] 1) The repair layer on the surface of the crystallization roller is BeNiCu alloy, and the diameter of the tapered hole defect is The depth is 5mm, and the method of combining drilling and grinding is used to process it into a diameter A columnar flat-bottomed hole with a depth of h=5.5mm, and the inner wall roughness is Ra0.7μm; use a V4 steel wire tap to process the inner wall texture, and process it into a wave texture structure, the distance between adjacent textures is A=2.0mm, and the peak-to-valley difference B=0.35mm .

[0046] 2) The utilization pressure value is 0.5MPa, the preheating temperature is 45°C, and the oil content is less than 0.7mg / m 3 , The gas-solid two-phase flow formed by compressed air with a maximum dust particle size of less than 0.8 μm and zirconia particles with a particle size of 360 μm is used for inner wall grinding. Among them, the feeding rate of ceramic particles is 0.5L / h, and the impact speed is 106m / s , spherical ceramic partic...

Embodiment 3

[0050] 1) The surface repair layer of the crystal roller is pure copper, and the diameter of the tapered hole defect is The depth is 6mm, and the corundum grinding head with a grain size of 120μm is directly ground to a diameter For columnar flat-bottomed holes with a depth of h=7mm, the inner wall roughness is Ra0.45μm; the inner wall texture is processed by high-speed steel wire tapping, and processed into a wave texture structure, the distance between adjacent textures is A=2.2mm, and the peak-to-valley difference B=0.5mm.

[0051] 2) The utilization pressure value is 0.7MPa, the preheating temperature is 80°C, and the oil content is less than 0.9mg / m 3 , The gas-solid two-phase flow formed by compressed air with a maximum dust particle size of less than 0.5 μm and silicon carbide particles with a particle size of 580 μm is used for inner wall grinding. Among them, the feeding rate of ceramic particles is 0.8L / h, and the impact speed is 60m / s , spherical ceramic particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com