A kind of metal layered composite material multi-head casing drawing compound preparation method

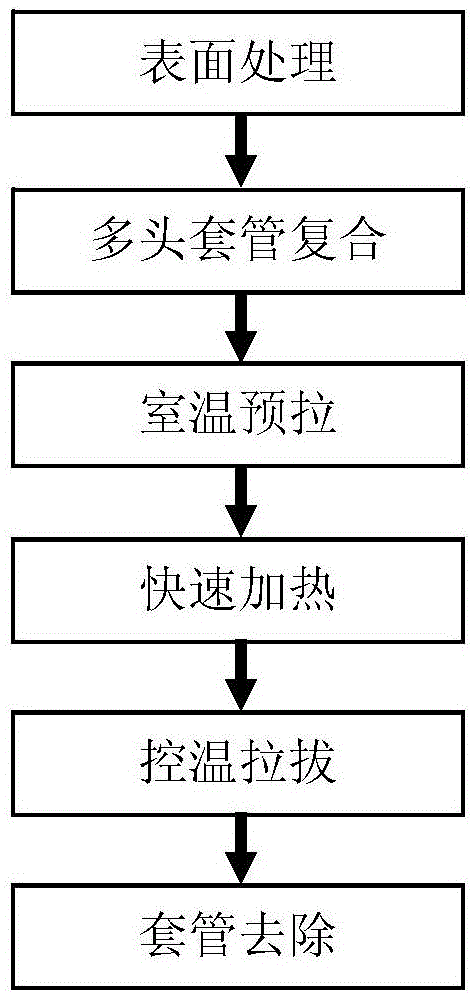

A composite material and metal casing technology is applied in the field of drawing and composite preparation of metal layered composite material multi-head casings, which can solve the problems of difficult to process dissimilar metal wires, difficult and short processes, etc., and achieves easy automation and mass production. Simple, thin diffuser effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Clean the inner surface of an annealed T2 pure copper sleeve (size Φ8×1mm), an annealed pure copper wire (diameter Φ2.9mm), and a drawn pure aluminum wire after surface cleaning at room temperature (diameter Φ2.9mm) surface is polished with a grinding wheel; at room temperature, pure copper wire and pure aluminum wire are put into the pure copper sleeve in parallel at the same time to obtain a combined blank; coated on the outer surface of the pure copper sleeve and the entrance area of the mold Graphite emulsion lubricant, single-pass drawing at room temperature for combined blanks to achieve pre-compounding, the drawing deformation rate is 10%, and local preliminary close adhesion between pure copper wires, pure aluminum wires and pure copper casings is obtained Under the protection of argon, put the pre-composite billet into the off-line tubular resistance furnace with a furnace temperature of 300 ° C and heat it for 3 minutes, so that the temperature can quickly re...

Embodiment 2

[0028] After surface cleaning at room temperature, the inner surface of an annealed T2 pure copper sleeve (size Φ8×1mm), an annealed pure copper wire (diameter Φ2.9mm), and an annealed BFe10-1- 1 The surface of the cupronickel wire (diameter Φ2.9mm) is repeatedly polished with 60# sandpaper; at room temperature, the pure copper wire and the BFe10-1-1 cupronickel wire are put into the pure copper sleeve in parallel at the same time to obtain the combined blank; The outer surface of the casing and the entrance area of the mold are coated with graphite emulsion lubricant, and the combined billet is drawn in a single pass at room temperature to achieve pre-compounding. The drawing deformation rate is 15%, and pure copper wire and BFe10-1-1 cupronickel wire are obtained. The pre-composite blanks that are initially tightly bonded between each other and the pure copper sleeve; under the protection of argon, put the pre-composite blanks into an off-line tubular resistance furnace wit...

Embodiment 3

[0030]Clean the inner surface of 1 annealed T2 pure copper sleeve (size Φ8×1mm), 2 annealed pure copper wires (diameter Φ2.4mm), and 2 annealed BFe10-1- 1 The surface of the cupronickel wire rod (diameter Φ2.4mm) is polished with a steel brush; at room temperature, the pure copper wire rod and the BFe10-1-1 cupronickel wire rod are put into the pure copper sleeve at intervals and parallel at the same time to obtain a combined blank; in the pure copper sleeve The outer surface of the tube and the entrance area of the mold are coated with graphite emulsion lubricant, and the combined billet is drawn in a single pass at room temperature to achieve pre-compounding. The drawing deformation rate is 10%, and the pure copper wire and the BFe10-1-1 cupronickel wire are obtained. The pre-composite billets that are initially closely attached between the space and the pure copper sleeve; under the protection of argon, the pre-composite billets are rapidly heated to the drawing temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com