Blade of sorting machine

A sorting machine and blade technology, applied in the direction of solid separation, separating solids from solids with airflow, furnace types, etc., can solve the problems of reduced production efficiency, economic loss of enterprises, lack of toughness, etc., and improve the economic efficiency of enterprises , Improve the service life and increase the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

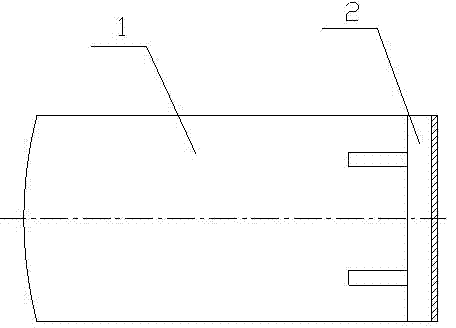

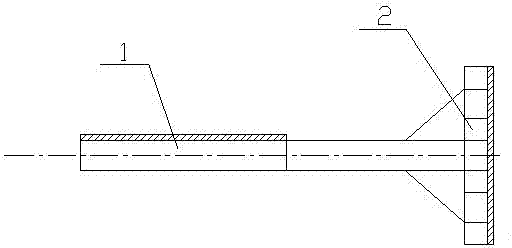

[0027] Refer to attached figure 1 , 2 , the present invention includes a blade working surface 1 and a blade rear mounting seat 2, the thickness of the front section of the blade working surface is 24mm, and the thickness of the blade rear mounting seat is 16mm, and the length of the front section of the blade working surface accounts for the length of the blade working surface 55% to 67% of that.

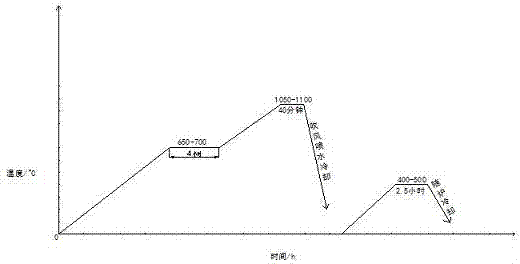

[0028] The separator blade of the present invention is realized through the following specific production techniques. The specific implementation adopts the casting process: making models---paint preparation---hanging sand (painting)---packing---melting and pouring---clearing and polishing---heat treatment---finished product storage.

[0029] 1. Make the model: use polystyrene (EPS) material. According to the drawing requirements of the sorter blade, the shrinkage rate of the model is 2%. Shaped with a molding machine. Special attention: increase the thickness of the vulnerab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com