Preparation method of high-gloss rutile titanium dioxide

A rutile type titanium dioxide, high gloss technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment and other directions, can solve the problems of particle slurry instability, precipitation, deterioration of dispersion performance, etc. The effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

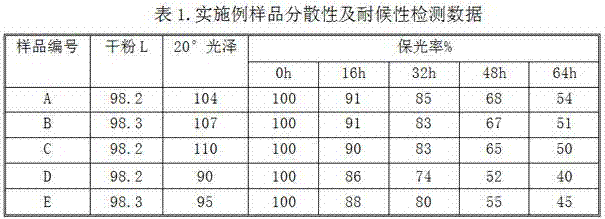

Embodiment 1

[0017] The qualified TiO will be pulverized through the sand milling process 2 Heat the slurry to about 45-55°C, add a dispersant, adjust the pH=10.0-10.5, and add metered zirconium sulfate at one time within 60 minutes, and the added amount is expressed as ZrO 2 / TiO 2 =0.8%, then use sodium hydroxide to slowly adjust the pH of the system between 10.0-10.5, mature for 30 minutes, cool the material to 40°C, sand mill for 5 minutes, then raise the temperature to 45°C, and add sodium metaaluminate and sulfuric acid solution, the amount of sodium metaaluminate added is Al 2 o 3 / TiO 2 =3.5%, adjust the pH of the system between 10.0-10.5, mature for 30min, adjust the slurry to neutral, wash with water, organically treat and jet mill to obtain rutile titanium dioxide sample A, and test the 20° gloss and weather resistance of the product.

Embodiment 2

[0019] The qualified TiO will be pulverized through the sand milling process 2 Heat the slurry to about 45-55°C, add a dispersant, adjust the pH=10.0-10.5, and add metered zirconium sulfate at one time within 60 minutes, and the added amount is expressed as ZrO 2 / TiO 2 =0.8%, then use sodium hydroxide to slowly adjust the pH of the system between 10.0-10.5, mature for 30 minutes, cool the material to 35°C, sand mill for 20 minutes, then raise the temperature to 50°C, and add sodium metaaluminate and sulfuric acid in parallel solution, the amount of sodium metaaluminate added is Al 2 o 3 / TiO 2 =3.5%, adjust the pH of the system between 10.0-10.5, mature for 30min, adjust the slurry to neutral, wash with water, organically treat and jet mill to obtain rutile titanium dioxide sample B, and test the 20° gloss and weather resistance of the product.

Embodiment 3

[0021] The qualified TiO will be pulverized through the sand milling process 2 Heat the slurry to about 45-55°C, add a dispersant, adjust the pH=10.0-10.5, and add metered zirconium sulfate at one time within 60 minutes, and the added amount is expressed as ZrO 2 / TiO 2 =0.8%, then use sodium hydroxide to slowly adjust the pH of the system between 10.0-10.5, mature for 30 minutes, cool the material to 30°C, sand mill for 30 minutes, then raise the temperature to 55°C, and add sodium metaaluminate and sulfuric acid in parallel solution, the amount of sodium metaaluminate added is Al 2 o 3 / TiO 2 =3.5%, adjust the pH of the system between 10.0-10.5, mature for 30min, adjust the slurry to neutral, wash with water, organically treat and jet mill to obtain rutile titanium dioxide sample C, and test the 20° gloss and weather resistance of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com