Ohmic contact production method of aluminum gallium nitride and gallium nitride HEMT (High Electron Mobility Transistor)

A high electron mobility, ohmic contact technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of difficult ohmic contact, increased contact resistance, etc., and achieve smooth metal topography, better edge, edge neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

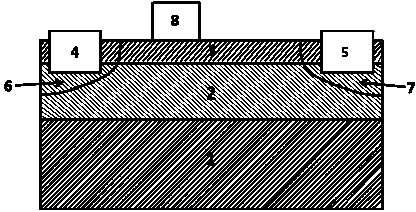

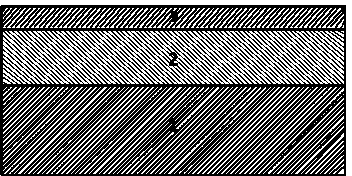

[0063] Non-alloy ohmic contact embodiment 1, source and drain etching of photoresist mask

[0064] Coating photoresist 17 on sheet surface, as Figure 12 shown. The pattern is defined by exposure and development. The etched area is within the implanted area and smaller than the implanted area. The distance between the boundary of the etched area and the implanted area is between 100 and 500 nm, forming a pattern such as Figure 13 structure shown. AlGaN and GaN are difficult to be wet etched, but they can be etched by Cl 2 etch away. Commonly used dry etching methods include RIE and ICP. Here, the ICP etching method is used to etch away the AlGaN barrier layer. After cleaning and degumming, it is formed as Figure 14 The structure shown, 18, represents the recessed region formed after the barrier layer has been etched away.

[0065] like Figure 15 As shown, the photoresist 19 is coated, exposed and developed to define source and drain patterns, such as Figure 16 show...

Embodiment 2

[0069] Non-alloy ohmic contact implementation 2, dielectric mask source and drain etching

[0070] The gas used in dry etching GaN and AlGaN is generally Cl-based gas, such as Cl 2 、BCl 3 etc.; while etching SiN usually uses F-based gases, such as SF 6 、CF 4 、CHF 3wait. Just based on the difference in etching selectivity between Cl-based and F-based gases for SiN and GaN (AlGaN), the present invention proposes to use SiN medium as the source-drain etching mask.

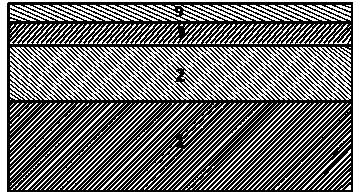

[0071] exist Figure 11 After removing the annealing protection medium, grow the SiN mask medium 28, such as Figure 21 shown. Coating photoresist 29 on sheet surface, as Figure 22 shown. The pattern is defined by exposure and development. The etched area is within the implanted area and smaller than the implanted area. The distance between the boundary of the etched area and the implanted area is between 100 and 500 nm, forming a pattern such as Figure 23 structure shown.

[0072] First, use F-based gase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com