Automotive hard magnetic brake pad formula and manufacturing method thereof

A production method and technology of brake pads, which are applied in the field of brake pad formulations, can solve the problems that magnetic field control does not have material conditions and technical foundations, and achieve the effects of improving braking performance and reliability, reducing wear rate, and weakening influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

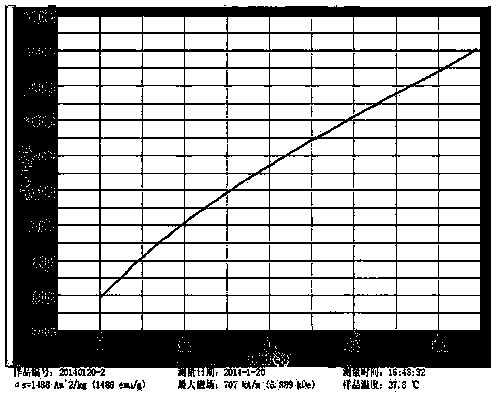

Image

Examples

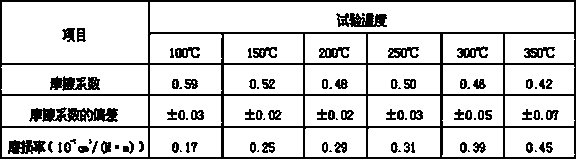

Embodiment 1

[0032] Organic binder: cashew nut shell oil modified phenolic resin 10 parts (cashew nut shell oil modified phenolic resin is a kind of modified phenolic resin), reinforcement material: steel fiber 16 parts, aramid fiber 4 parts, glass fiber 8 parts 7 parts of sepiolite fiber; friction modifier: 3 parts of graphite, 3 parts of molybdenum disulfide, 2 parts of zircon, 7 parts of chromite powder, 8 parts of feldspar, 9 parts of barite; filler: 4 parts of cashew nut shell oil friction powder, 2 parts of zirconium coupling agent (zirconium coupling agent is one of the coupling agents), 2 parts of release agent; hard magnetic material: 15 parts of NdFeB magnetic powder.

Embodiment 2

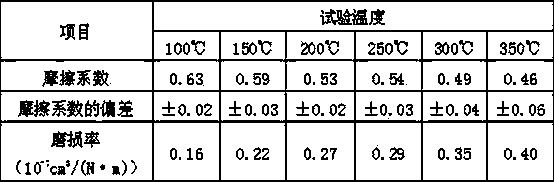

[0034] Organic binder: 10 parts of cashew nut shell oil modified phenolic resin, reinforcing material: 16 parts of copper fiber, 4 parts of aluminum silicate fiber, 8 parts of glass fiber, 7 parts of sepiolite fiber; friction modifier: 5 parts of graphite , 9 parts of wollastonite, 6 parts of marble, 8 parts of feldspar, 9 parts of barite; filler: 4 parts of cashew nut shell oil friction powder, 2 parts of zirconium coupling agent, 2 parts of release agent; hard magnetic material : Barium ferrite magnetic powder 10 parts.

Embodiment 3

[0036] Organic binder: 10 parts of nitrile modified phenolic resin (nitrile modified phenolic resin is a kind of modified phenolic resin), reinforcement material: 12 parts of steel fiber, 8 parts of copper fiber, 8 parts of glass fiber, sea 7 parts of foam stone fiber; friction modifier: 3 parts of graphite, 2 parts of molybdenum disulfide, 7 parts of zeolite, 8 parts of alumina, 8 parts of feldspar, 9 parts of barite; filler: 4 parts of cashew nut shell oil friction powder , 2 parts of silane coupling agent (silane coupling agent is one of the coupling agents), 2 parts of release agent; hard magnetic material: 15 parts of strontium ferrite magnetic powder.

[0037] The brake pads prepared in the three examples were subjected to constant pressure and constant speed tests on a friction standard testing machine, with a pressure of 0.98MPa and a speed of 16.7m / s, respectively at temperatures of 100°C, 150°C, 200°C, 250°C, Conduct friction tests at six temperature ranges of 300°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com