SiC (silicon carbide) content standard substance and preparation method thereof

A standard material, silicon carbide technology, applied in the field of analysis and testing, can solve the problems of poor uniformity, poor reliability, inaccurate nominal value, etc., and achieve the effect of strong component designability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Silicon carbide content standard material, pre-designed SiC content 80%, SiO 2 Content 10%, Al 2 o 3 Content 10%.

[0024] Silicon carbide pretreatment: silicon carbide with a particle size of 40nm (Shanghai Chaocheng Nano Technology Co., Ltd.) was burned at 600°C for 2h, and [H 2 O:H 2 o 2 (30%): NH 4 OH (27%)=5:2:1] heated and cleaned at (70~80)°C for 20 minutes, then ultrasonically cleaned for 30 minutes, stood for clarification, changed the water for the next rinse, repeated 5 times, and filtered; 2 O:H 2 o 2 (30%): HCl (37%)=6:1:1] heating and cleaning for 20min, ultrasonic cleaning for 30min, filtering; use aqua regia [HCl (37%):HNO 3 (67%)=3:1] Boil for 30min, then ultrasonically clean for 30min, filter; use HF acid and HNO 3 Acid mixture [HF(40%):HNO 3 (67%)=1:1] soaked in 30min, then rinsed with deionized water to neutral; then placed in a drying oven at 90 ° C to dry;

[0025] Preparation of hydrosol gel: Dissolve 40g (0.196 mol) aluminum isopropoxi...

Embodiment 2

[0031] SiC content standard material, pre-designed SiC content 70%, SiO 2 Content 15%, Al 2 o 3 15%.

[0032] The process of silicon carbide purification and value determination is the same as in Example 1. Silicon carbide is Shanghai Chaocheng Nano Technology Co., Ltd., with a particle size of 200nm.

[0033] Material composition: Tetraethyl silicate 52g (0.25 mole), water 85g, polyvinyl butyral 1.2g, isopropanol 85g, SiC70g, aluminum isopropoxide 60g (0.29 mole);

[0034] The sintering conditions are: heating rate 5°C / min, respectively at 150°C (40min heat preservation), 310°C (30min heat preservation), 390°C (30min heat preservation), 710°C (30min heat preservation), 790°C (30min heat preservation), and 860°C (keep warm for 30 minutes);

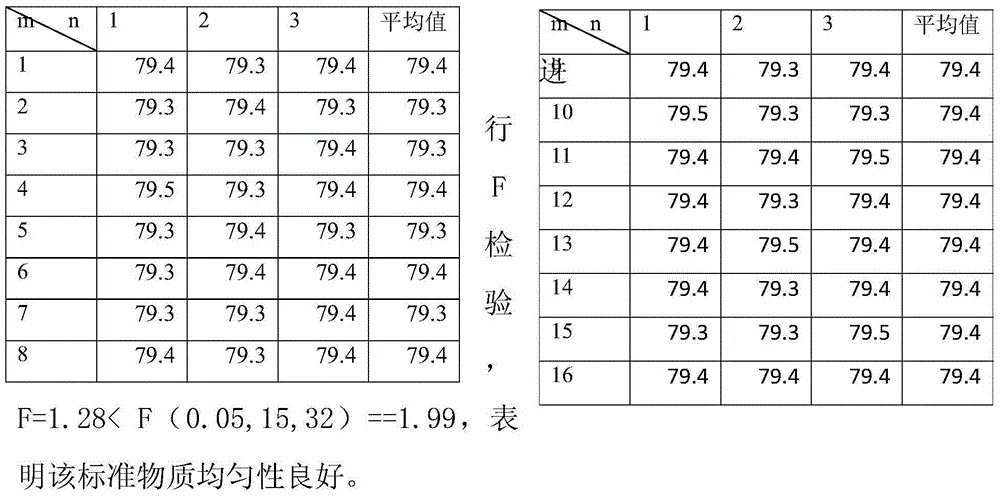

[0035] Determination of value: use CS844 carbon-sulfur analyzer to determine the value of the standard substance candidate, and the nominal value is 70.1%. F test: 16 bottles were sampled, and each bottle was tested 3 times, F=1.35<F...

Embodiment 3

[0037] SiC content standard material, pre-designed SiC content 60%, SiO 2 Content 18%, Al 2 o 3 twenty two%.

[0038] The process of silicon carbide purification and value determination is the same as in Example 1. Silicon carbide is silicon carbide from Shanghai Chaocheng Nano Technology Co., Ltd., with a particle size of 400nm.

[0039] Material composition: 62.4g (0.3 mole) of tetraethyl orthosilicate, 90g water, 1.3g polyvinyl butyral, 90g isopropanol, 60g SiC, 88g (0.43 mole) aluminum isopropoxide;

[0040] Sintering conditions: Helium protection, heating rate 10°C / min, respectively at 170°C (40min heat preservation), 310°C (30min heat preservation), 400°C (30min heat preservation), 700°C (35min heat preservation), 810°C (30min heat preservation) , 840°C (30 minutes of heat preservation);

[0041] Determination of value: use CS844 carbon-sulfur analyzer to determine the value of the standard substance candidate, and the nominal value is 60.3%. F test: 16 bottles were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com