A kind of preparation method of high tuning ratio bmnt film material

A thin-film material and harmonic rate technology, applied in the field of BMNT thin-film material preparation, can solve the problems of high driving voltage and low tuning rate, and achieve the effects of improving dielectric properties, improving dielectric tuning rate, and enhancing polarization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of target material

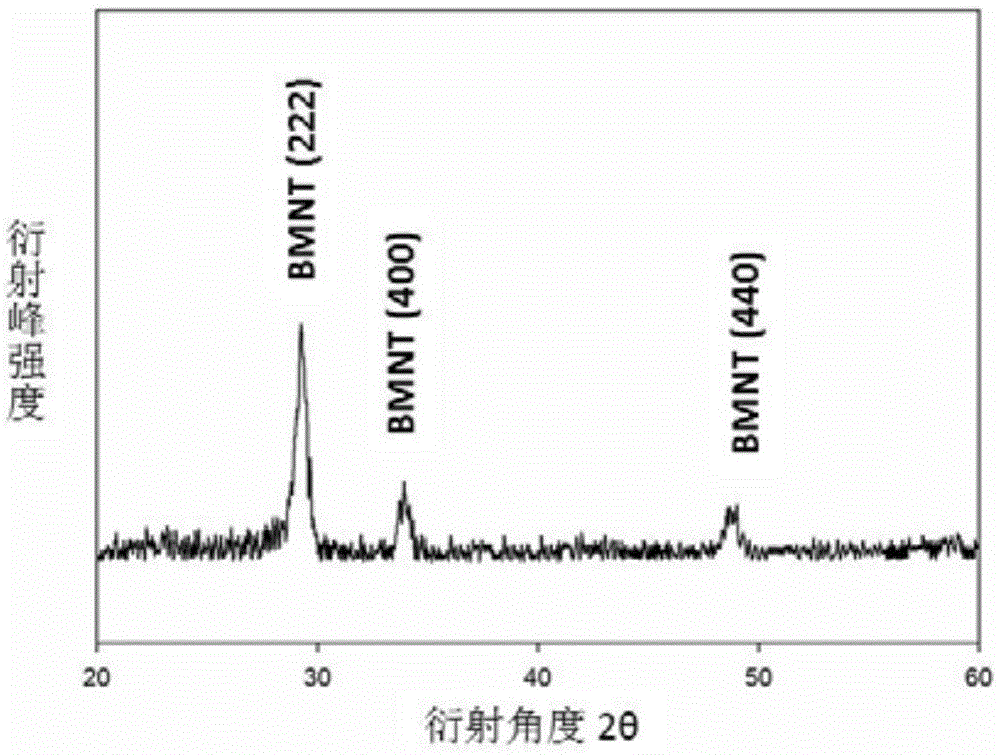

[0028] Using Bi with a purity of 99.99% 2 o 3 ,MgO,Nb 2 o 5 and TiO 2 oxides, Bi was prepared by a traditional solid-state reaction method 1.5 Mg 0.5 Nb 0.5 Ti 1.5 o 7 (BMNT) ceramic target with a relative density greater than 95%.

[0029] (2) Cleaning the substrate

[0030] The Si substrate with the Pt electrode attached to the surface is put into an organic solvent acetone for ultrasonic cleaning, rinsed with deionized water and dried in a nitrogen stream; the substrate can be a silicon substrate, an alumina substrate and a conductive glass substrate piece.

[0031] (3) Preparation of film

[0032] (a) Pump the background vacuum of the magnetron sputtering system to 6.0×10 -6 Torr, then heat the Pt-Si substrate to 450°C;

[0033] (b) with high purity (99.99%) Ar and O 2 As the sputtering gas, the flow ratio of argon and oxygen is 4:1; the sputtering pressure is 10mTorr, the sputtering power is 150W, and the BMNT fil...

Embodiment 2

[0039] The preparation process of Example 2 is the same as that of Example 1, except that the thickness of the deposited film is 300 nm. In Example 2, when the driving electric field is 1.2 MV / cm, the tuning rate is 36%.

Embodiment 3

[0041] The preparation process of Example 3 is the same as that of Example 1, except that the thickness of the deposited film is 100 nm. In Example 3, when the driving electric field is 1.2MV / cm, the tuning rate is 29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com