Preparation method for BMNT film material with high tunability

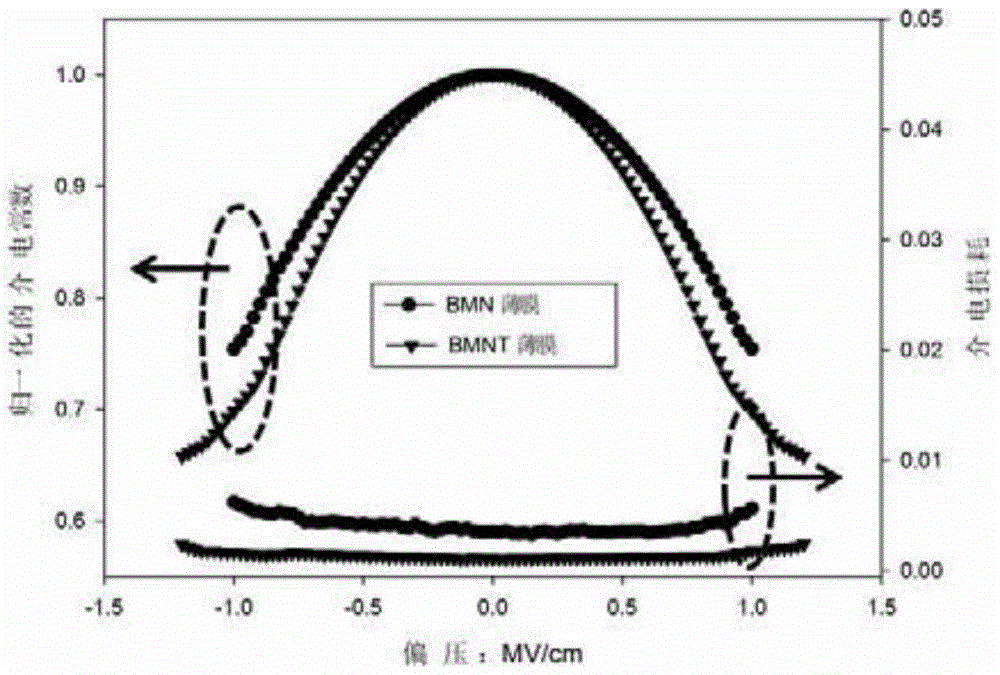

A technology of thin film material and harmonic ratio, which is applied in the field of preparation of BMNT thin film materials, can solve the problems of high driving voltage and low tuning rate, and achieve the effect of improving dielectric properties, improving dielectric tuning rate, and enhancing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of target material

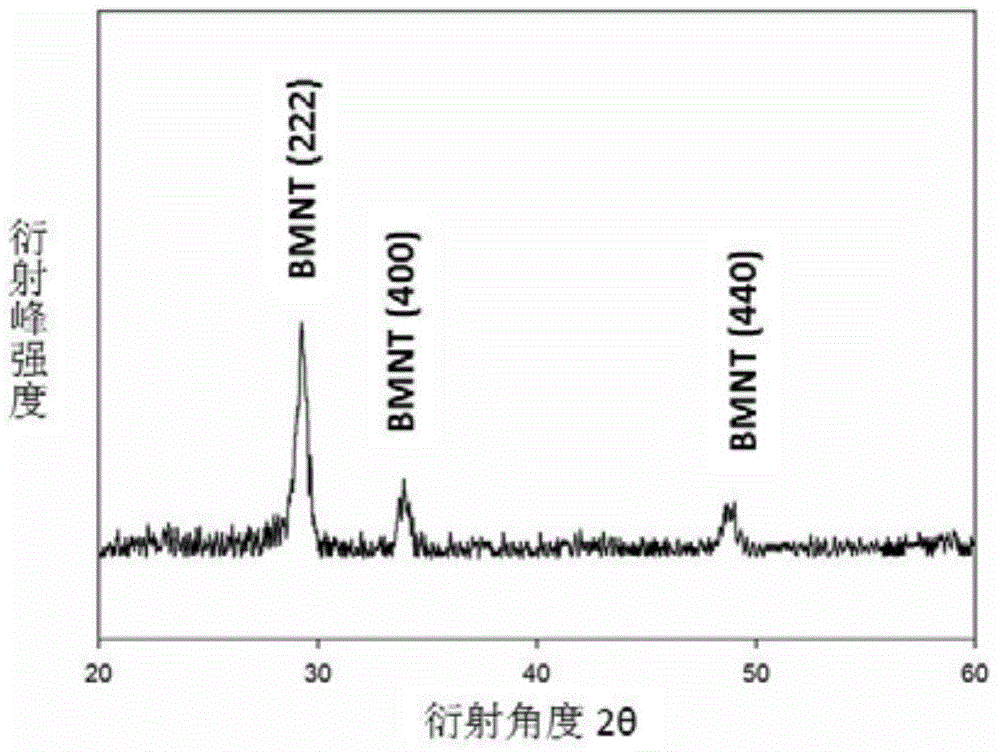

[0028] Using Bi with a purity of 99.99% 2 o 3 ,MgO,Nb 2 o 5 and TiO 2 oxides, Bi was prepared by a traditional solid-state reaction method 1.5 Mg 0.5 Nb 0.5 Ti 1.5 o 7 (BMNT) ceramic target with a relative density greater than 95%.

[0029] (2) Cleaning the substrate

[0030] The Si substrate with the Pt electrode attached to the surface is put into an organic solvent acetone for ultrasonic cleaning, rinsed with deionized water and dried in a nitrogen stream; the substrate can be a silicon substrate, an alumina substrate and a conductive glass substrate piece.

[0031] (3) Preparation of film

[0032] (a) Pump the background vacuum of the magnetron sputtering system to 6.0×10 -6 Torr, then heat the Pt-Si substrate to 450°C;

[0033] (b) with high purity (99.99%) Ar and O 2 As the sputtering gas, the flow ratio of argon and oxygen is 4:1; the sputtering pressure is 10mTorr, the sputtering power is 150W, and the BMNT fil...

Embodiment 2

[0039] The preparation process of Example 2 is the same as that of Example 1, except that the thickness of the deposited film is 300 nm. In Example 2, when the driving electric field is 1.2 MV / cm, the tuning rate is 36%.

Embodiment 3

[0041] The preparation process of Example 3 is the same as that of Example 1, except that the thickness of the deposited film is 100 nm. In Example 3, when the driving electric field is 1.2MV / cm, the tuning rate is 29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com