Metal graphene composite material and preparation method thereof

A metal graphite and composite material technology, applied in the field of materials, can solve the problems of reduced friction coefficient, consumption of large copper materials, easy graphitization, etc., to achieve the effect of improving lubricating performance, excellent mechanical properties, and improving lubricating life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

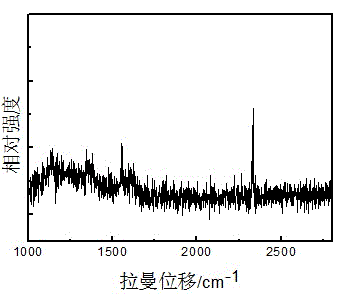

Image

Examples

Embodiment 1

[0028] 1. Form a copper infiltrated layer on the surface of 316L stainless steel substrate by using double-layer glow plasma surface metallurgy furnace

[0029] High-purity copper is used as the source target material required for the copper infiltration layer. The size of the target material is 100 mm × 100 mm × 5 mm, and the purity is 99.99%. The copper target was polished with sandpaper to expose a fresh surface, cleaned with acetone and ultrasonic, and dried.

[0030] Use 1000# sandpaper to remove the surface passivation layer on the surface of 316L stainless steel, and polish it with diamond abrasive paste, and then clean it ultrasonically with acetone.

[0031] In the double-layer glow plasma surface metallurgical furnace, the pretreated 316L stainless steel is used as the workpiece pole, placed on the base plate and protected by a heat preservation cover; the pretreated copper target is fixed on the workpiece pole as the source, and the 316L stainless steel The distanc...

Embodiment 2

[0044] 1. A double-layer plasma surface metallurgical furnace is used to form a copper infiltrated layer on the surface of another material base of Q235 steel

[0045] The copper material is used as the source target material, and it is made into a cuboid structure with a size of 100 mm×100 mm×5mm (what size??), and a purity of 99.99%. The copper material was polished with sandpaper to expose a fresh surface, cleaned with acetone and ultrasonic, and dried.

[0046] The surface of Q235 steel was removed with 1000# sandpaper to remove the surface passivation layer, polished with diamond abrasive paste, and then ultrasonically cleaned with acetone.

[0047] Put the pretreated Q235 steel as the workpiece electrode, put it on the base plate and protect it with a heat preservation cover; fix the pretreated copper material as the source electrode above the workpiece electrode, and the distance between the Q235 steel and the copper material is the electrode spacing, which is 18mm . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com