Wet magnetic separation process for recycling iron in iron-containing waste

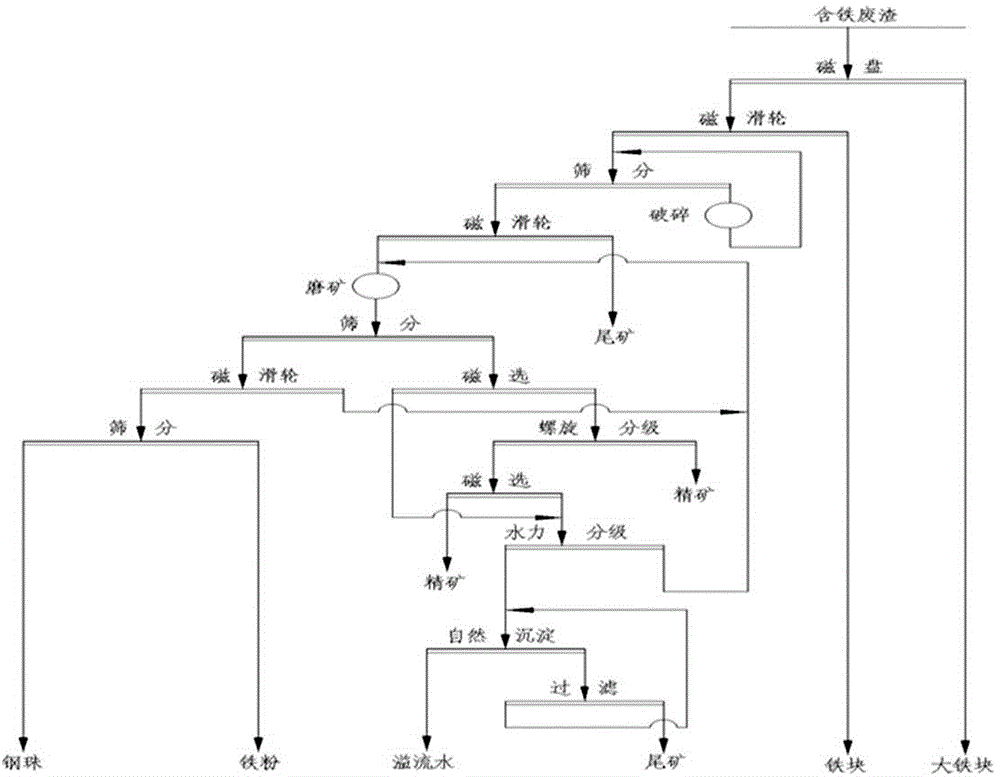

A technology for recovering iron and wet magnetic separator, which is applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of small investment, low magnetic separation efficiency, and high metal iron content in steel tailings, and achieves a simple process. , the effect of high economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The desulfurization slag produced in the steelmaking process with a total iron grade of 40% is passed through a magnetic disk with a magnetic field strength of 1000mT, and the large iron block in the steel slag is selected, and the total iron grade of the selected large iron block reaches 95%; the large iron block will be selected The final tailings pass through a magnetic pulley with a magnetic field strength of 800mT to select the small iron nuggets, and the total iron grade of the selected small iron nuggets reaches 93%; the tailings after the small iron nuggets are selected are passed through double-layer sieves, The size of the upper sieve hole is 80mm, and the size of the lower sieve hole is 20mm. After screening, the material larger than 20mm is crushed by the crusher, and the crushed material is returned to the double-layer sieve for screening; the material smaller than 20mm enters the magnetic field. The 200mT magnetic pulley is used for magnetic separation; the...

Embodiment 2

[0047] Pass the casting slag with a total iron grade of 30% produced in the steelmaking process through a magnetic disk with a magnetic field strength of 1200mT, select large iron blocks in the steel slag, and select large iron blocks with a total iron grade of 93%; The tailings after the block are passed through a magnetic pulley with a magnetic field strength of 700mT to select the small iron blocks, and the total iron grade of the selected small iron blocks reaches 91%; the tailings after the small iron blocks are selected through double-layer sieves , the size of the upper sieve hole is 75mm, and the size of the lower sieve hole is 15mm. After screening, the material larger than 15mm is crushed by the crusher, and the crushed material is returned to the double-layer sieve for screening; the material smaller than 15mm enters the magnetic field strength Magnetic separation is carried out for a 300mT magnetic pulley; the magnetic material after passing through the 300mT magnet...

Embodiment 3

[0049] Pass the ditch iron with a total iron grade of 35% produced in the ironmaking process through a magnetic disk with a magnetic field strength of 1000mT, select a large iron block in the steel slag, and the selected large iron block has a total iron grade of 91%; the large iron block will be selected The final tailings pass through a magnetic pulley with a magnetic field strength of 600mT to select the small iron nuggets, and the total iron grade of the selected small iron nuggets reaches 90%; the tailings after the small iron nuggets are selected are passed through double-layer sieves, The size of the upper sieve hole is 85mm, and the size of the lower sieve hole is 15mm. After screening, the material larger than 85mm is crushed by the crusher, and the crushed material is returned to the double-layer sieve for screening; the material smaller than 15mm enters the magnetic field. The 400mT magnetic pulley is used for magnetic separation; the magnetic material after passing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com