Surface-modified radiofrequency ablation needle and its application

A technology of radiofrequency ablation and surface modification, applied in the field of tumor treatment, can solve the problems of poor surface smoothness of radiofrequency needles, poor material, poor elasticity and toughness, and affect medical safety, and achieve low friction, high hardness, and good blood compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

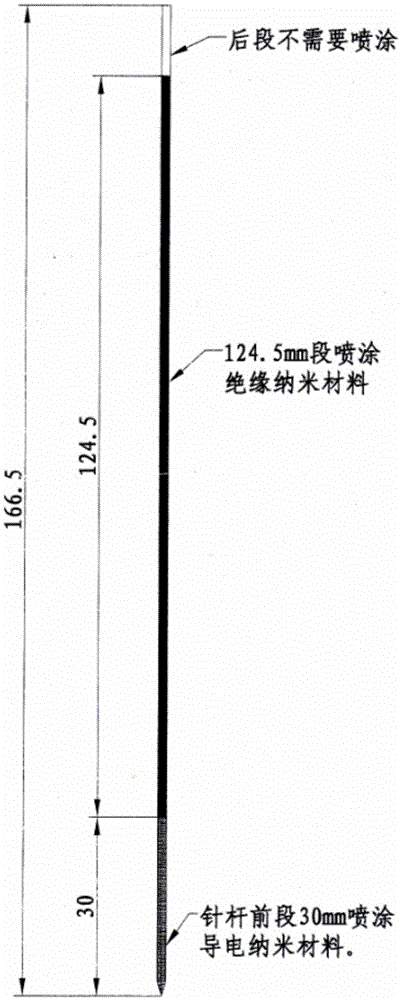

[0032] (1) Conductive layer: The needle tip of the radiofrequency ablation needle is modified with nanometer materials by ion implantation modification.

[0033] The needle tip of the radiofrequency ablation needle (16.65 cm in length, 18 G in diameter, 12.45 cm in length of the needle shaft, and 3 cm in length of the needle tip) was placed in the hollow space of a double-bend magnetic filter cathodic arc composite magnetron sputtering coating device (purchased from Ningbo Institute of Materials, Chinese Academy of Sciences). In the chamber, vacuumize, and then pass the acetylene gas with a flow rate of 20 sccm into the hollow chamber where the needle tip of the radio frequency ablation needle is placed through the ion source, and the ion source current is 0.10A, and then use titanium as the sputtering target material to inject into the sputtering target Introduce argon gas, the flow rate of argon gas is 40sccm, the argon gas sputtering current is 2A, the bias voltage is -100V,...

Embodiment 2

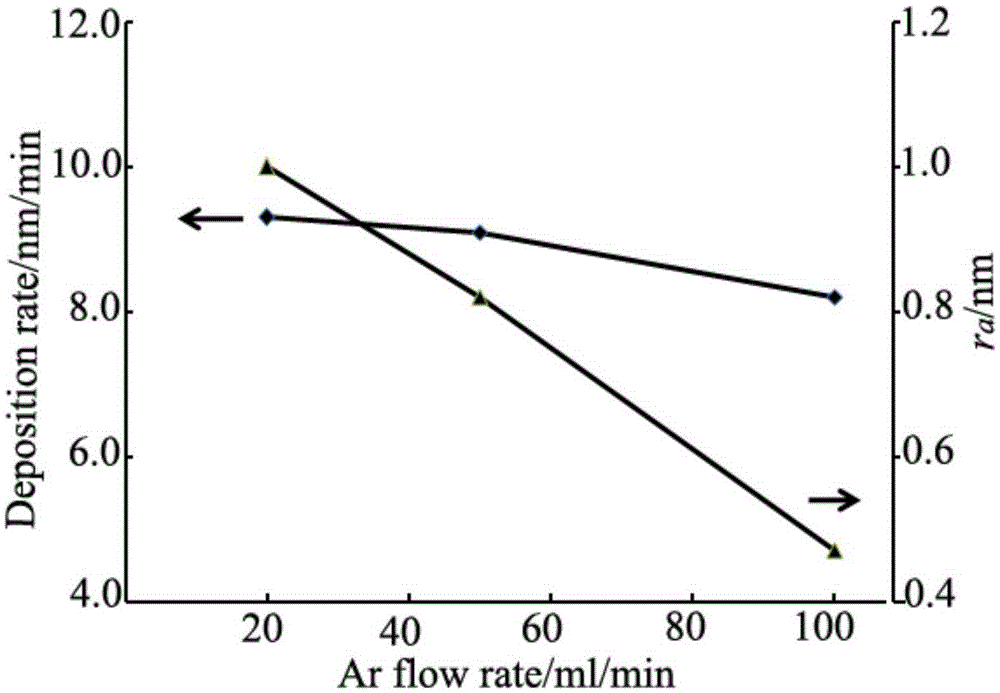

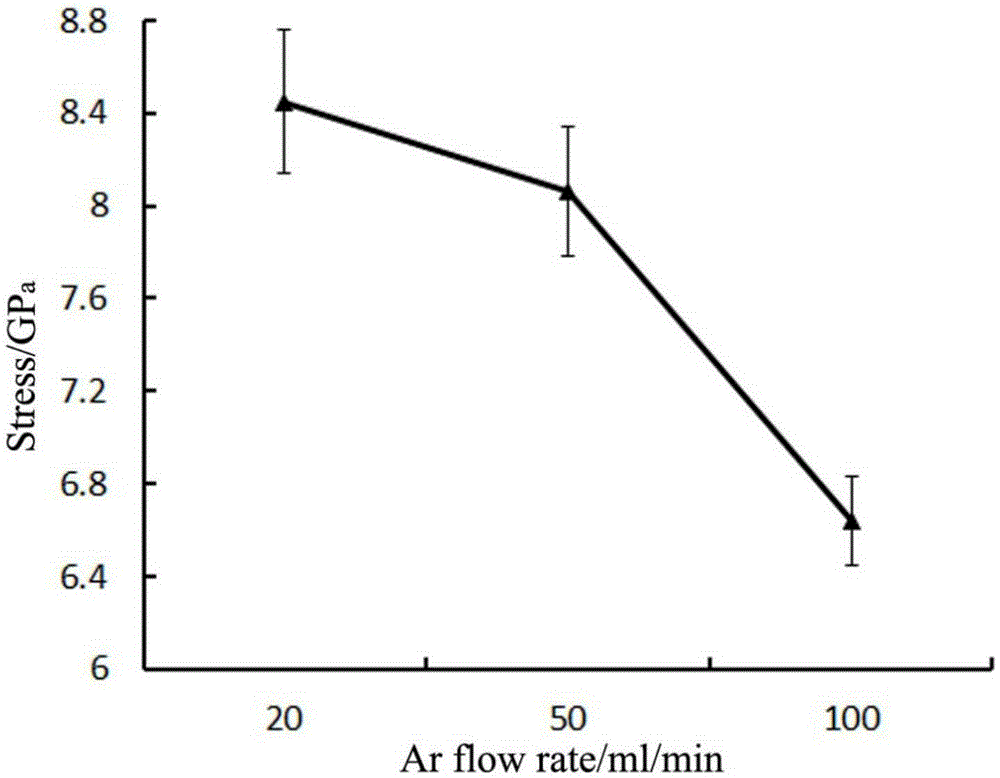

[0037] Change the argon flow in the Ti / DLC porous film formation process in step (1) of Example 1 to 20, 50, and 100ml / min respectively, and other operations are the same as in Example 1 to obtain a Ti with a thickness of 4 to 5 μm and a surface pore size of 600 to 800 nm. / DLC porous film layer, detecting the changes in the tetrahedral amorphous carbon film structure and friction properties of the Ti / DLC porous film prepared under different Ar flow conditions ( figure 2 ), the change of membrane stress ( image 3 ), and the change in the average coefficient of friction ( Figure 4 ).

[0038] (1) Tetrahedral amorphous carbon film structure and friction properties

[0039] The roughness and thickness of the film were characterized by a surface profiler (KLaTencorAlpha-StepIQ, ScientechCo., USA). The friction performance decreased gradually from 9.5nm / min at 20ml / minAr flow rate to 8.2nm / min at 100ml / minAr flow rate, and as the Ar flow rate increased, the surface roughness ...

Embodiment 3

[0047] Embodiment 3 antibacterial properties

[0048] 1. Materials

[0049] Strains: Staphyloccocus aureus (Staphyloccocusaureus), Candida albicans (C.albicans), Escherichia coli (Escherichiacoli) were purchased from Beijing National Institute for the Control of Pharmaceutical and Biological Products (National Institute for the Control of Pharmaceutical and Biological Products, NICPBP).

[0050] Conductive nanometer surface modification material Ti / Ti-DLC porous membrane: prepare a Ti / Ti-DLC porous membrane with a thickness of 4 to 5 μm and a surface pore diameter of 600 to 800 nm according to the method of the conductive layer in step (1) of Example 1, and mix Ti / Ti-DLC porous membrane is sprayed on the surface of stainless steel cylinder (1.5*2*2cm size, Figure 7 shown in B).

[0051] Non-conductive nano-surface modification material Ti / DLC composite layer: according to the method for the non-conductive layer in the embodiment 1 step (2), prepare the non-conductive nano-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com