Method for preparing nitrogen-containing carbon nano tube

A nanotube and nitrogen carbon technology is applied in the field of nitrogen-doped graphitized carbon nanomaterials and their synthesis, which can solve the problems of difficult control and low yield, and achieve the effects of easy control, low reaction temperature and uniform nitrogen distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

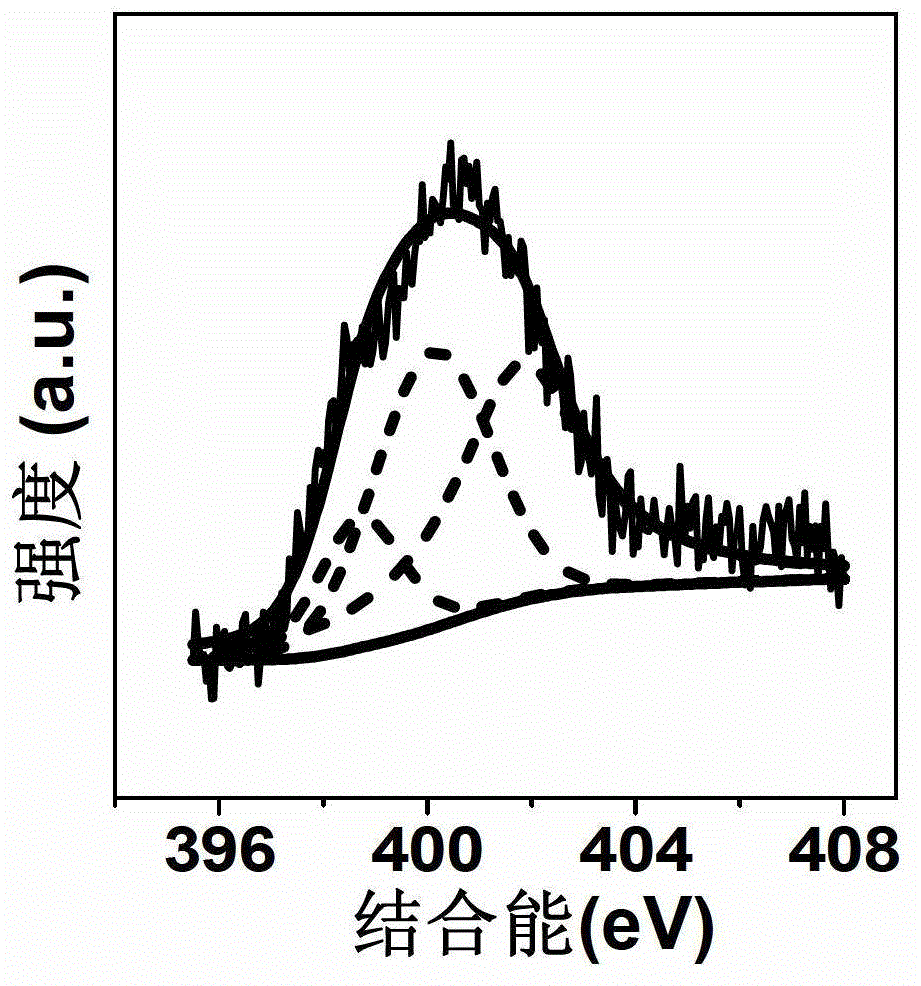

[0040] Under the condition of stirring at room temperature, add dissolved metal ions Zn(NO 3 ) 2 , FeSO 4 The DMF solution was stirred at room temperature for half an hour, then transferred to a crystallization kettle and sealed, crystallized at 140°C for 48h, cooled to room temperature, centrifuged, and dried at 100°C for 24h to obtain an imidazole polymer material , SEM results show that it is a microsphere with uniform particle size and good dispersion ( figure 1 ); in a nitrogen atmosphere, put Zn-Fe-ZIFs spheres into a tube furnace, carbonize at 900°C for 4h; add the carbonized product into aqua regia, stir at room temperature for 4h and then centrifuge; wash with deionized water until neutral, 100 ℃ of drying 24h, thereby made product. SEM results show that the product obtained is a carbon nanotube ( figure 2 ). The XPS results of N1s of the obtained product show that nitrogen in carbon nanotubes contains three states: graphitized N (binding energy is 401.8eV), pyr...

Embodiment 2

[0042] Using the preparation process of Example 1, the difference is that before the imidazole polymer material is put into the tube furnace for carbonization, it is first dispersed in a DMF solution (1.5M) with dicyandiamine dissolved in it, and the dicyandiamine is adjusted. The amount that makes the mass ratio of dicyandiamide and imidazole polymer material is 2.5, stirred at room temperature for 2 hours, then spin-dried, and the solid obtained was put into a tube furnace for carbonization at 700°C for 3h under nitrogen atmosphere, carbonization The product was dispersed in aqua regia, stirred at room temperature for 20 min, washed with deionized water until neutral, and dried at 100° C. for 24 h to obtain the product. SEM results show that the product obtained is a carbon nanotube ( Figure 5 ). TEM results showed that the obtained product was bamboo-shaped and contained metal nanoparticles ( Figure 6 ), the XPS results of N1s of the obtained product show that nitrogen ...

Embodiment 3

[0044] Using the preparation process of Example 2, the difference is that the amount of dicyandiamine is adjusted so that the mass ratio of dicyandiamine to imidazole polymer material is 5, and the rest of the synthesis process is exactly the same. SEM results show that the obtained product is a carbon nanotube ( Figure 8 ). TEM results showed that the obtained product was bamboo-shaped and contained metal nanoparticles ( Figure 9 ), the XPS results of N1s of the obtained product show that nitrogen in carbon nanotubes contains three states: graphitized N (binding energy is 401.8eV), pyrrole N (binding energy is 400.1eV), pyridine N (binding energy Can be 398.7eV) ( Figure 10 ), the nitrogen content of the elemental analysis characterization product is 10.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com