Functional circuit board core board with the function of absorbing instant high-voltage electric pulse energy and manufacturing method thereof

A high-voltage electric pulse, functional circuit board technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit components, etc., can solve the problems of increased risk of circuit board delamination, powerlessness, loss of function, etc., to enhance the reliability of equipment Sexuality, simple and flexible use, and the effect of improving equipment functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is based on the technical invention of the Chinese patent ZL201210314982.2, and aims to completely solve the problem of the electronic circuit of the electronic device against the impact of the instantaneous high-voltage electric pulse energy.

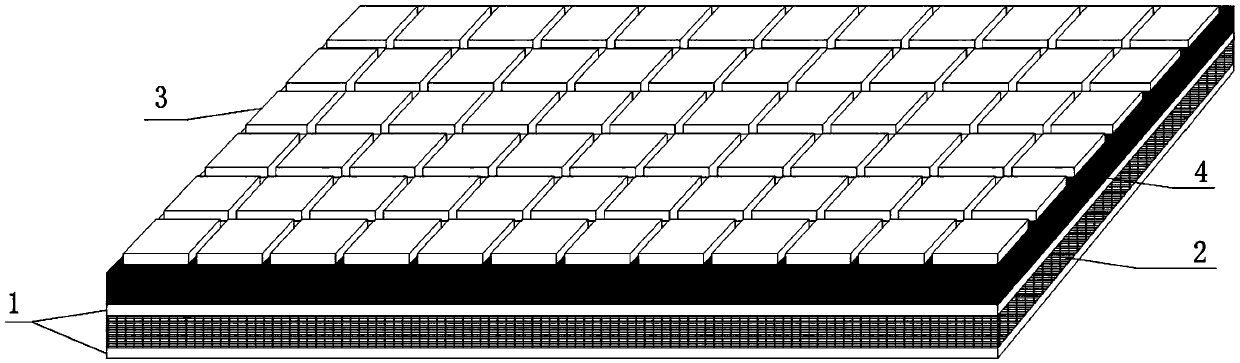

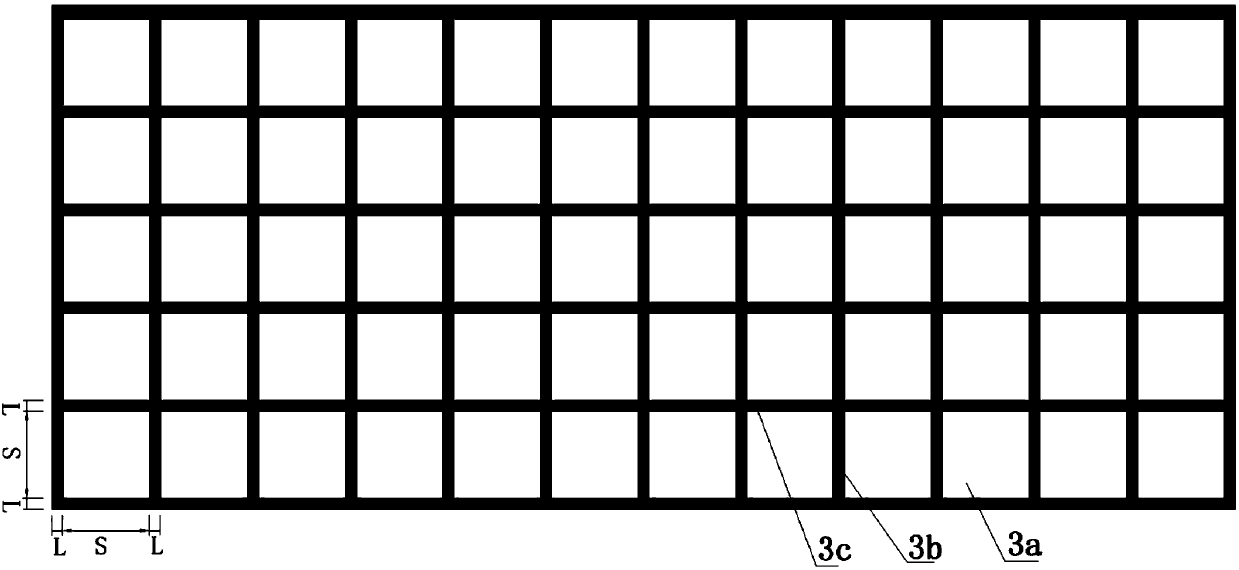

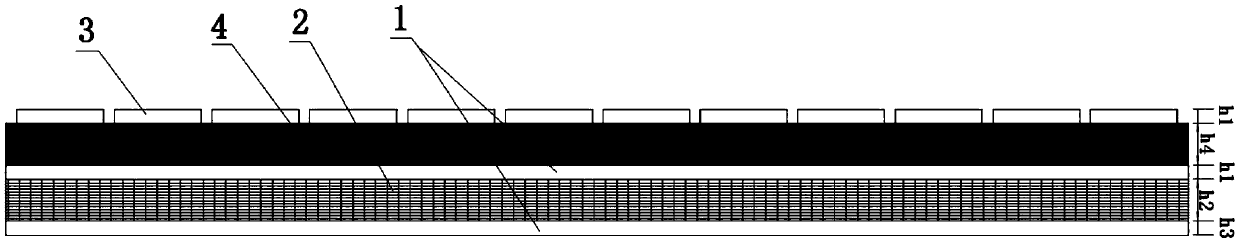

[0041] figure 1 , image 3 It is a schematic diagram of the three-dimensional structure of the core board of the circuit board with the function of absorbing the instantaneous high-voltage electric pulse energy of the present invention.

[0042] The core board of the circuit board with the function of absorbing instantaneous high-voltage electric pulse energy of the present invention includes a basic core board composed of an insulating layer 2 and a metal substrate 1 above and below the insulating layer 2, and a layer attached to the metal substrate 1 on one side of the basic core board. The voltage variable resistance functional material layer 4, the voltage variable resistance functional material layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com