Semi-interpenetrating intelligent hydrogel and preparation method and application thereof

A semi-interpenetrating, hydrogel technology, used in pharmaceutical formulations, medical preparations with inactive ingredients, aerosol delivery, etc., can solve the problems of long response time of gel materials, and achieve improved biocompatibility, Improved mechanical performance and improved response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

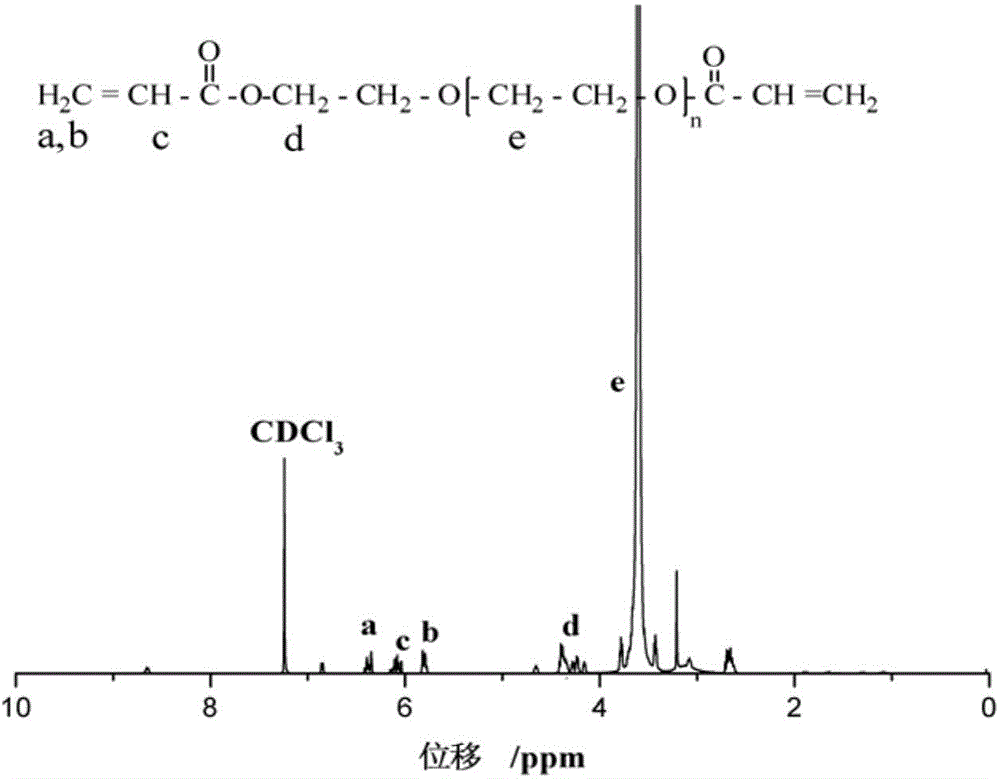

[0053] The preparation process of polyethylene glycol diacrylate (PEGDAc) used in Examples 3 to 6 is as follows: 6 g of PEG was dissolved in 50 ml of dichloromethane, 1 ml of acrylic acid and 0.1 g of 2-methylaminopyridine were added, mixed evenly, and the , another 1g of N,N-dicyclohexylcarbodiimide was dissolved in 20ml of dichloromethane, slowly added to the above solution under ice-cooling, and reacted at room temperature for 48h. The reaction solution was washed once with 1M hydrochloric acid solution, twice with saturated sodium carbonate solution, and three times with distilled water, dried over anhydrous magnesium sulfate, and then rotary evaporated to obtain polyethylene glycol diacrylate, which was designated as PEGDAc. Its H 1 NMR spectrum see figure 1 , resulting in:

[0054] δ=3.58~3.63(t, 4H, -OCH 2 CH 2 ); δ=4.31~4.39(m, 2H, -CH 2 ); δ=5.77~5.80, 6.32~6.4(m, 2H,=CH 2 ); δ=6.03~6.11 (m, 1H, =CH-).

Embodiment 2

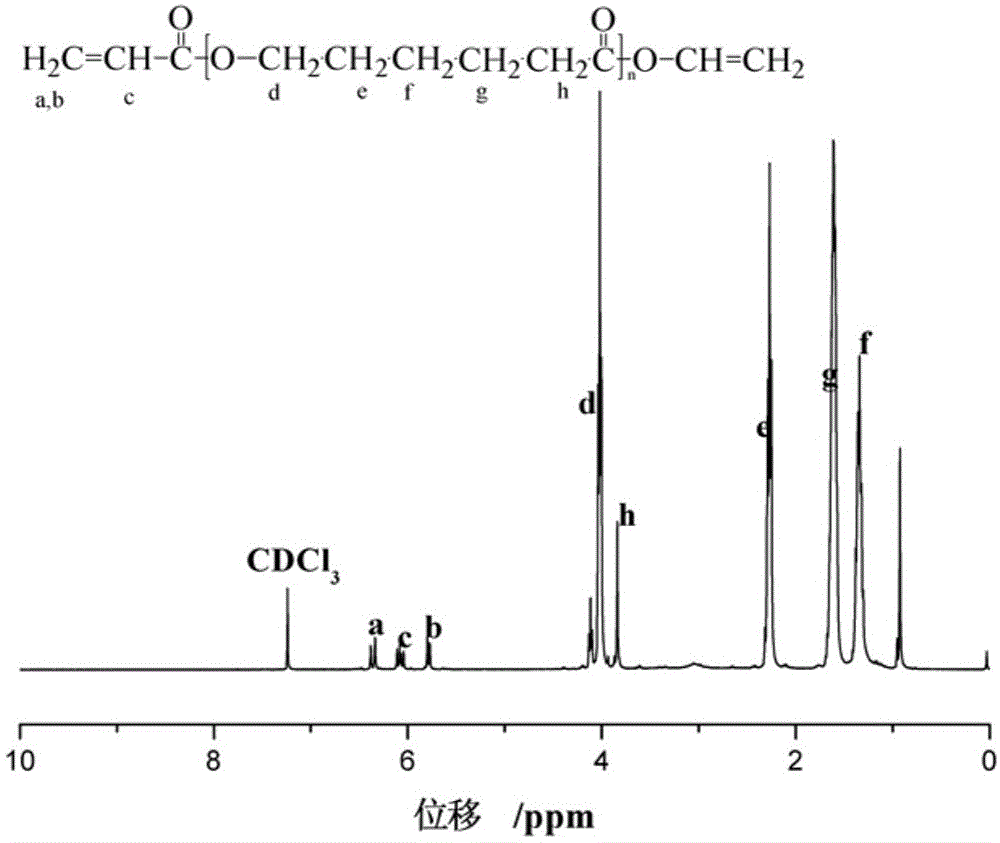

[0056] The preparation process of polycaprolactone diacrylate (PCLDAc) used in implementation 3-6 is as follows: get 10g of polycaprolactone diol and dissolve it in 100ml of dichloromethane, add 1g of triethylamine, stir well, and Under protection, another 0.75 g of acryloyl chloride was mixed with 20 ml of dichloromethane, and slowly added dropwise to the above solution under ice bath, and reacted at 40° C. for 24 hours after the dropwise addition was completed. The reaction solution was washed once with 1M hydrochloric acid solution, twice with saturated sodium carbonate solution, and three times with distilled water, dried over anhydrous magnesium sulfate and then rotary evaporated to obtain polycaprolactone diacrylate, which was designated as PCLDAc. Its H 1 NMR spectrum see figure 2 , resulting in:

[0057] δ = 1.31 ~ 1.35 (m, 2H, -CH2-); δ = 1.58 ~ 1.61 (m, 2H, -CH 2 -); δ=2.26~2.31(m, 2H, -CH 2 -); δ=3.8~3.81(t, 2H, -CH 2 -C=O); δ=4.05~4.1(t, 2H, -CH 2 -O-); δ=5....

Embodiment 3

[0061] Weigh 0.0300g of PEGDAc, 0.0200g of PCLDAc, 0.3990g of N-isopropylacrylamide, and 0.0080g of acrylamide, dissolve them in 2ml of 1,4-dioxane, mix them uniformly by ultrasonication for 15 minutes, then add 6mg of azobisisobutylcyanide, After fully mixing, freeze-thaw cycle deoxygenation, react at 65°C for 48 hours under the protection of argon, crush the reactor, soak the gel in distilled water for 4 days, change the water every day, and remove unreacted particles to obtain the composite cross-linking agent intelligent hydrogel Glue, cut into 10mm*5mm cylindrical small pieces for later use, recorded as AAm2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com