Method for preparing ethyl alcohol and isopropyl alcohol

A technology of isopropanol and ethanol, which is applied in the field of catalysis, can solve the problems of high cost of use and difficulty in industrial application, and achieve the effects of low cost, mild reaction conditions and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

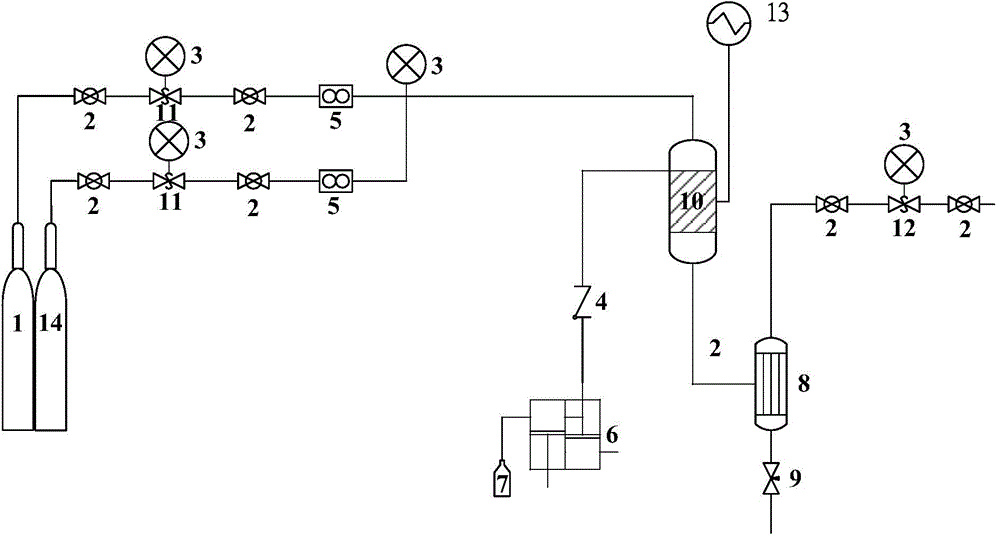

Method used

Image

Examples

Embodiment 1

[0025] Copper oxide-based catalysts were prepared by co-precipitation method. The copper oxide-based catalyst includes copper oxide, a promoter and a carrier, wherein the promoter includes one of zinc oxide, chromium oxide, nickel oxide, cobalt oxide, samarium oxide, neodymium oxide, etc. One or more mixtures, the carrier is one or more than two of alumina, cerium oxide, zirconia, titanium oxide, molecular sieve, etc. mixed.

[0026] The weight percentage of each component in the copper oxide-based catalyst is as follows: copper oxide accounts for 3wt%-50wt%, co-catalyst accounts for 3wt%-50wt%, and carrier accounts for no more than 95wt%. The more optimal composition range of the catalyst is that the copper oxide accounts for 25wt%-35wt%, the co-catalyst accounts for 10wt%-20wt%, and the carrier accounts for 20wt%-40wt%. Example 2

Embodiment 2

[0027] Take by weighing 18.7 grams of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) and 23.0 grams of zinc nitrate (Zn(NO 3 ) 2 ·6H 2 0) be placed in a beaker, be mixed with the metal salt solution of 1.5mol / L with pure water dissolving; The solution was slowly added dropwise into the precipitation reactor, the pH value of the precipitation was controlled between 7 and 8, the precipitation temperature was 60°C, and the precipitation was left to stand for 24 hours. Suction filter, wash, and dry the precipitate at 90°C for 12 hours at a constant temperature. After granulation, it is calcined in a muffle furnace at 400°C to obtain the final catalyst after a certain period of time.

[0028] Get above-mentioned catalyzer 5.0 grams and place in fixed-bed reactor and reduce, reduce in volume ratio 35%H 2 / N 2 Reduction in air flow, reduction temperature 300°C, normal pressure, space velocity 500h -1 , The reduction time is 8 hours. After the reduction, replace the whole system with p...

Embodiment 3

[0030] Weigh 9.2 grams of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), 17.0 grams of zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) and 27.4 grams of aluminum nitrate (Al(NO 3 ) 3 9H 2 O) be placed in a beaker, dissolved with pure water to prepare a 1.0mol / L metal salt solution; take a certain amount of sodium hydroxide and place it in a beaker, and prepare a 1.0mol / L solution, and mix the metal salt solution with hydrogen The sodium oxide solution was slowly added dropwise into the precipitation reactor, the pH value of the precipitation was controlled between 7 and 8, the precipitation temperature was 60°C, and the precipitation was left to stand for 12 hours. The precipitate was suction filtered, washed, and dried at a temperature of 90° C. and kept at a constant temperature for 12 hours. Then place it in a muffle furnace for calcination at 400°C, and obtain the final catalyst after a certain period of time.

[0031] Get above-mentioned catalyzer 5.0 grams and place in fixed-bed reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com