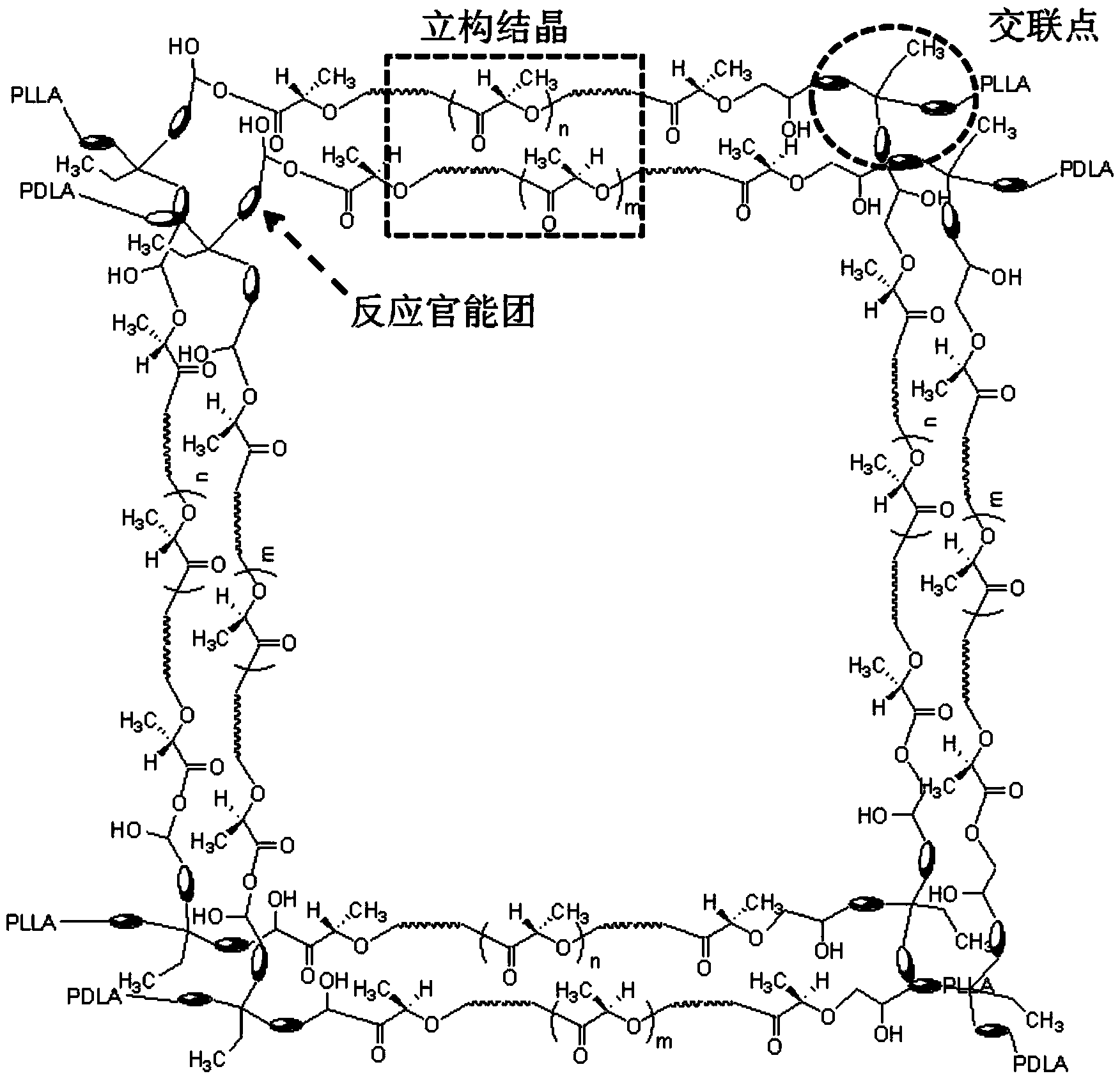

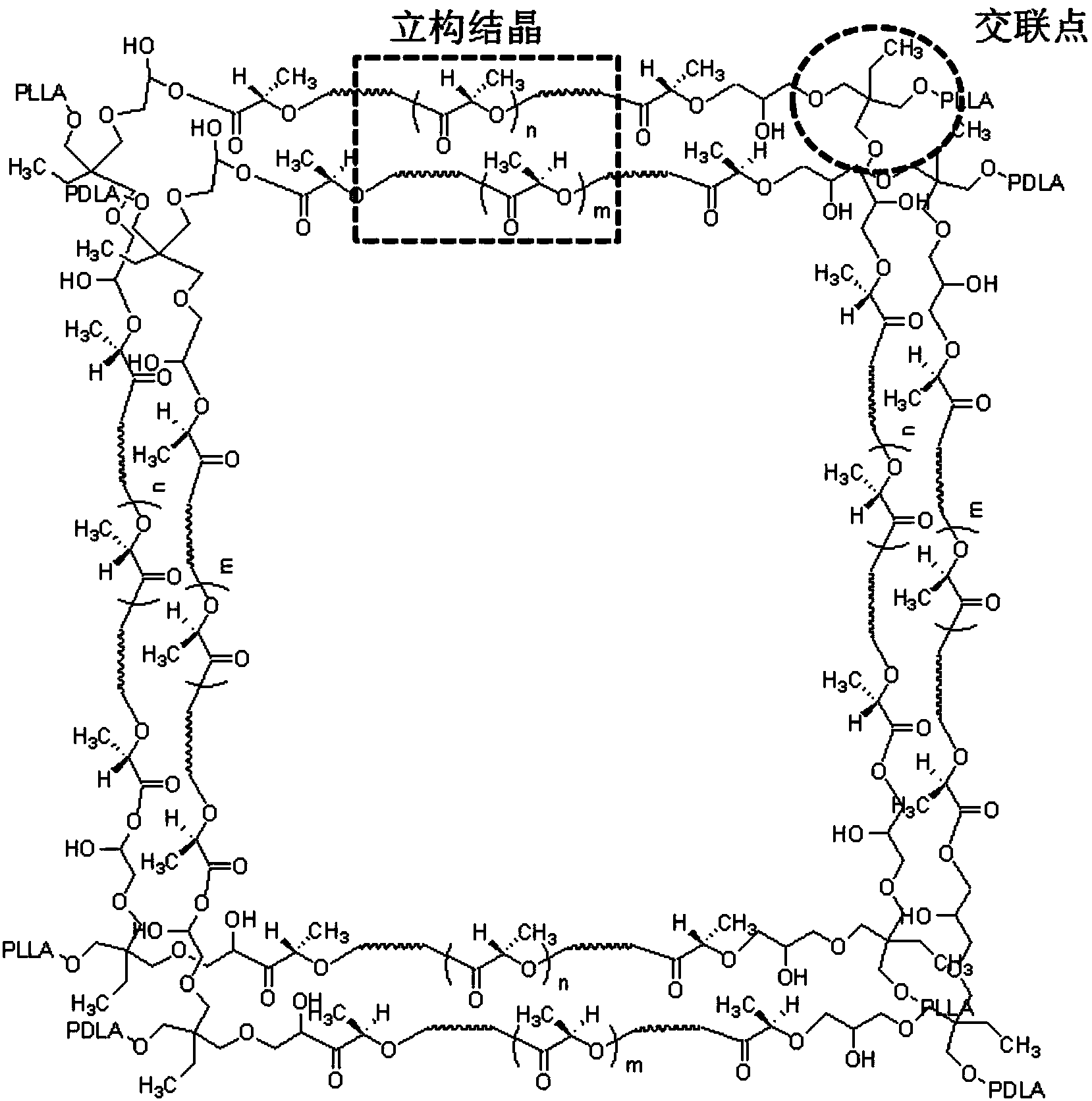

Poly lactic acid stereocomplex with interpenetrating network structure and preparation method thereof

A technology of interpenetrating network structure and stereocomplex, which is applied in the field of polylactic acid stereocomplex and its preparation, can solve the problems of difficult structure control, poor stability, large environmental protection pressure, etc., and achieves easy operation and high reliability. Effects of repeatability, high heat resistance temperature and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

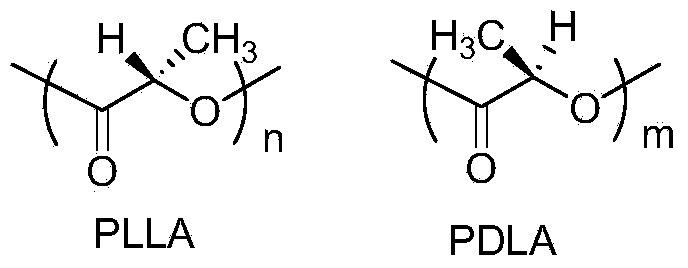

Method used

Image

Examples

Embodiment 1

[0029] Put 50 parts by weight of L-lactide in a reaction kettle with a stirring blade, add 0.003 parts by weight of initiator stannous octoate, and carry out the reaction under a nitrogen atmosphere at a temperature of 120°C for 2 hours, and the reaction ends Finally, after removing the residual L-lactide under reduced pressure, add 5 parts by weight of the crosslinking agent styrene-glycidyl methacrylate random copolymer, and continue to control the temperature to carry out the polymerization reaction at 160°C for 30 minutes. To obtain cross-linked PLLA, then, add 50 parts by weight of D-lactide and 0.003 parts by weight of initiator stannous octoate, control the temperature and carry out the reaction at 160°C for 2 hours, and remove the remaining D-lactide under reduced pressure to obtain Polylactic acid stereocomplex with semi-interpenetrating network structure. The gel content of the product and the melting enthalpy and melting point of polylactic acid were tested. The res...

Embodiment 2

[0031] Put 30 parts by weight of L-lactide in a reaction kettle with a stirring blade, add 0.001 parts by weight of initiator stannous octoate, and carry out the reaction under nitrogen atmosphere at a controlled temperature of 120°C for 2 hours. After the reaction , after removing residual L-lactide under reduced pressure, add 0.5 parts by weight of cross-linking agent lysine triisocyanate, continue to control the temperature and carry out polymerization reaction at 180°C for 30 minutes to obtain cross-linked PLLA, and then add 70 parts by weight of D - Lactide and 0.002 parts by weight of the initiator stannous octoate, the temperature is controlled at 160 ° C for 1 hour of polymerization reaction, the temperature is raised to 220 ° C and the reaction is continued for 2 hours to complete the reaction, the remaining D-lactide is removed under reduced pressure, and then , adding 0.5 parts by weight of a cross-linking agent lysine triisocyanate, controlling the temperature and r...

Embodiment 3

[0033] Put 70 parts by weight of L-lactide in a reaction kettle with a stirring blade, add 0.005 parts by weight of initiator stannous octoate, and carry out the reaction at 120°C under nitrogen atmosphere for 2 hours, and remove under reduced pressure After the residual L-lactide, add 10 parts by weight of cross-linking agent polydicyclohexylmethane carbodiimide, continue to control the temperature and react at 160°C for 30 minutes to obtain cross-linked PLLA, then add 30 parts by weight D-lactide and 0.001 parts by weight of the initiator stannous octoate, the temperature was controlled at 160 ° C for 1 hour, and then the temperature was raised to 220 ° C intermittently for 2 hours to complete the reaction, and the remaining D-lactide was removed under reduced pressure. ester, and then add 5 parts by weight of cross-linking agent polydicyclohexylmethanecarbodiimide, and control the temperature at 220° C. for 30 minutes to form a polylactic acid stereocomplex with a completely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com