A kind of composite crystal type bismuth iron phosphate lithium battery cathode material and preparation method thereof

A technology of lithium bismuth iron phosphate and battery positive electrode, which is applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of low product density, difficulty and high manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

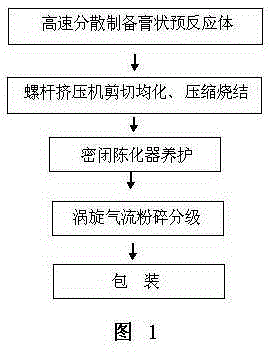

[0035] 1) Mix dilithium hydrogen phosphate, iron oxide, bismuth nitrate, and phosphoric acid in a high-speed mixer according to the effective element molar ratio Li:Fe:Bi:P=0.8:0.9:0.15:1, and add 10% of the mass of Tian Qing glue, add the crystal complex agent triethanolamine of total mass 0.2% simultaneously, and high-speed stirring disperses with the speed of 500rpm 30min to obtain pasty colloid pre-reaction body;

[0036] 2) Pump the pasty colloid pre-reaction body obtained in step 1) into a conical screw extruder. The screw extruder is composed of conveying thread elements, engaging thread elements, and compression thread elements arranged on the mandrel in a building block. Conveying drying section, shearing homogenization section, and compression sintering section. Control the screw temperature: conveying drying section 160°C, shearing homogenization section 200°C, compression sintering section 300°C, and the screw produces continuous shear under the condition of 200rpm ...

Embodiment 2

[0041] 1) Mix lithium carbonate, ferric chloride, bismuth nitrate, and diammonium hydrogen phosphate in a high-speed mixer according to the effective element molar ratio Li:Fe:Bi:P=0.8:0.8:0.3:1, and add 15% of the total mass % carboxymethyl starch glue, add the 0.5% crystal formation complex agent triethanolamine of total mass simultaneously, and obtain the pasty colloid pre-reaction body with the high-speed stirring dispersion 10min of the speed of 1000rpm;

[0042] 2) Pump the pasty pre-reaction body obtained in step 1) into a conical screw extruder. The screw extruder is composed of conveying thread elements, meshing thread elements, and compression thread elements arranged on the mandrel in a building block to form a conveying There are three parts: drying section, shearing homogenization section, and compression sintering section. Control the screw temperature: conveying drying section 120°C, shearing homogenization section 180°C, compression sintering section 300°C, and th...

Embodiment 3

[0047] 1) In a high-speed mixer, mix lithium dihydrogen phosphate, iron nitrate, bismuth nitrate, and ammonium dihydrogen phosphate according to the effective element molar ratio Li:Fe:Bi:P=0.8:0.8:0.2:1, and add the total mass of 20% guar gum, while adding 1% crystal complex agent triethanolamine of the total mass, and stirring and dispersing at a high speed of 800rpm for 20min to obtain a paste colloid pre-reaction body;

[0048] 2) Pump the pasty pre-reaction body obtained in step 1) into the screw extruder, and the screw extruder consists of conveying thread elements, meshing thread elements, and compression thread elements arranged on the mandrel in a building block form to form a conveying drying section 1, shear homogenization section, compression sintering section, control screw temperature: conveying drying section 150°C, shear homogenization section 200°C, compression sintering section 360°C, the screw produces continuous shear homogenization under the rotation condit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com