Metal cord thread and rubber tire

A metal cord and cord technology, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve the problems of service life discount, easy breakage of steel cords, influence of breaking tension, etc., and achieve fracture extension. High rate and structural elongation, improved adhesive performance, and the effect of satisfying full adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

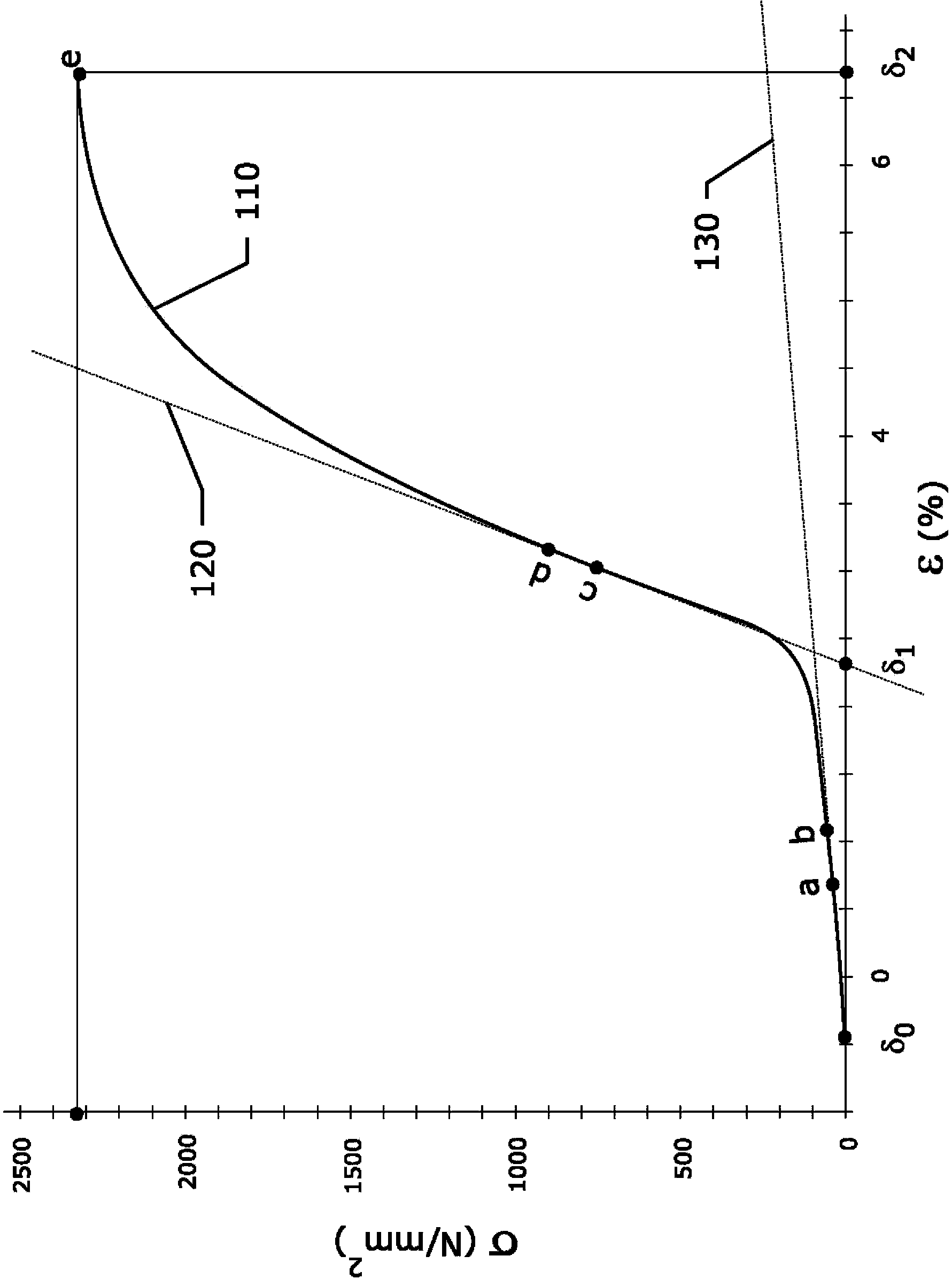

[0037] The test method of structural elongation and elongation at break of steel cord in the present invention is as figure 1 shown. exist figure 1 Among them, the curve 110 is the tensile curve of the steel cord, by figure 1 It can be seen that 110 first undergoes the structural deformation stage of the steel cord and then enters the elastic deformation stage; 120 is the elastic modulus line (take any two points c and d in the elastic deformation stage of the tensile curve 110, and the straight line connecting the two points is the elastic modulus line 120); the intersection point of the reverse extension line of 120 and the abscissa is denoted as δ1; 130 is the structural deformation regression line (take any two points a and b in the structural deformation stage of the tensile curve 110, and connect the two points. That is, the structural deformation regression line 130); the intersection point of the reverse extension line of 130 and the abscissa, denoted as δ 0 . |δ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com