Reverse osmosis membrane with high flux and high desalination rate and preparation method thereof

A reverse osmosis membrane, high desalination technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as unsatisfactory, high flux, desalination rate, and lower desalination rate, and the method is simple , Improve permeability, good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 takes polysulfone as the preparation of the reverse osmosis membrane of base membrane

[0033] According to the knowledge already mastered by those skilled in the art, the non-woven polysulfone ultrafiltration membrane is used as the substrate, and the substrate is sequentially passed through the water phase solution tank with a mass fraction of 4.5% m-phenylenediamine by using a coating device to remove excess water. After the phase is passed through a tank of trimesoyl chloride isoparaffin solution with a mass fraction of 0.3%, the water phase and the oil phase are interfacially polymerized at the water-oil interface, and then dried in an oven at 60° C. to obtain a reverse osmosis membrane.

Embodiment 2

[0034] Embodiment 2 takes polyolefin as the preparation of the reverse osmosis membrane of base film

[0035] Similarly, according to the knowledge already mastered by those skilled in the art, a commercially available lithium-ion battery separator (such as the HS20 product sold by Shanghai Enjie Company) is wetted in isopropanol, and then rinsed with pure water until the isopropanol is completely replaced. Propanol, spread the wet PE-based film on a glass plate, remove excess water with a rubber roller, and fix a silica gel frame on the surface of the film, pour a 4.5% m-phenylenediamine aqueous solution into the silica gel frame and soak for 60s, Then remove the excess water phase on the surface of the membrane, quickly pour the isoparaffin solution of trimesoyl chloride with a mass fraction of 0.3% into a silica gel frame for interfacial polymerization reaction for 60 seconds, and then dry it in an oven at 60°C to obtain a reverse osmosis membrane .

Embodiment 3~6

[0036] Embodiment 3~6 investigates the influence of different solvents on the performance of the reverse osmosis membrane of embodiment 1

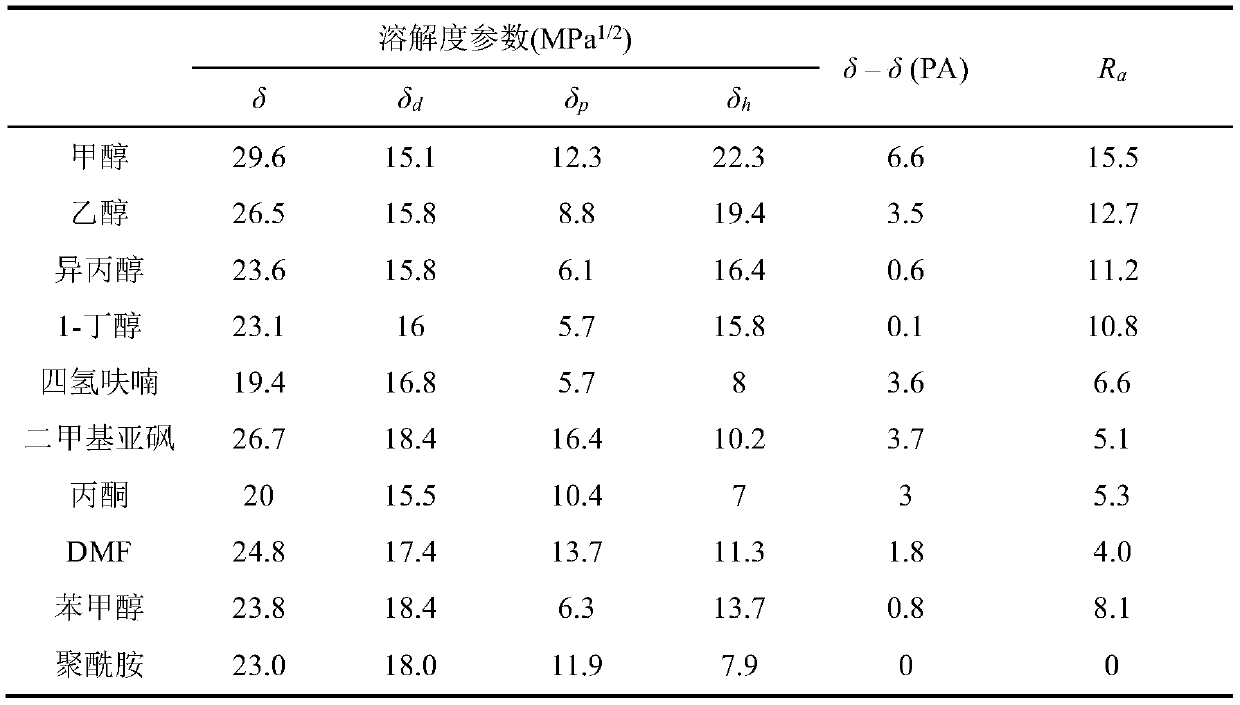

[0037] Configure benzyl alcohol, benzyl alcohol / isopropanol with a volume ratio of 3:1, benzyl alcohol / isopropanol with a volume ratio of 2:1 and benzyl alcohol / isopropanol with a volume ratio of 1:1, according to the teaching of the prior art ( As by the method taught in Charles M. Hansen's HANSENSOLUBILITY PARAMETERS A User's Handbook), calculate and confirm the difference R of each solvent with polyamide in three-dimensional space a Both satisfy the relationship 4.0≤R a ≤15.5.

[0038] Soak the polysulfone reverse osmosis membrane in Example 1 in the above solvent for 20 seconds respectively, as Examples 3-6. Then rinse with deionized water to completely remove the residual organic solvent on the membrane, and finally dry it.

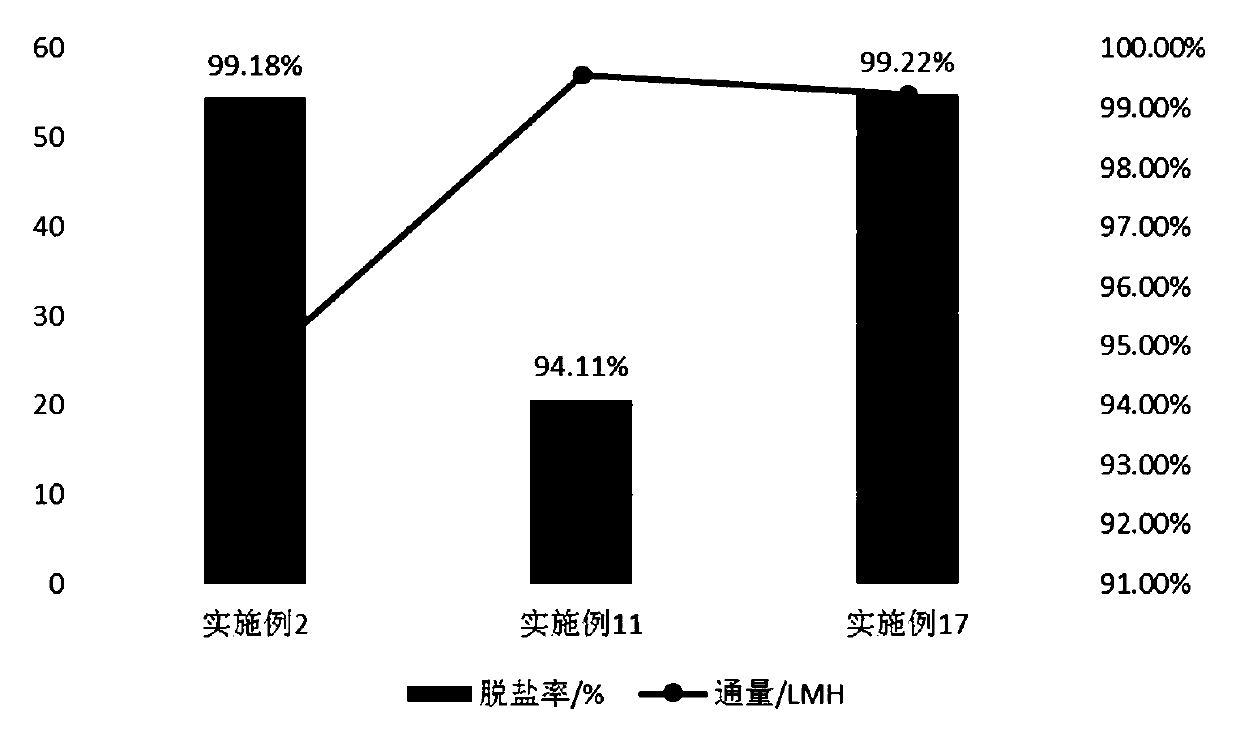

[0039] At 150psi and water temperature 20-28℃, the effective area of the membrane is 42.40cm 2 The flux an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com