A modified reverse osmosis membrane prepared by a core-shell nanoparticle with hierarchical porous structure

A nanoparticle and reverse osmosis membrane technology, applied in the field of membrane separation, can solve the problem of low mass transfer coefficient, achieve the effect of improving structural stability and increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

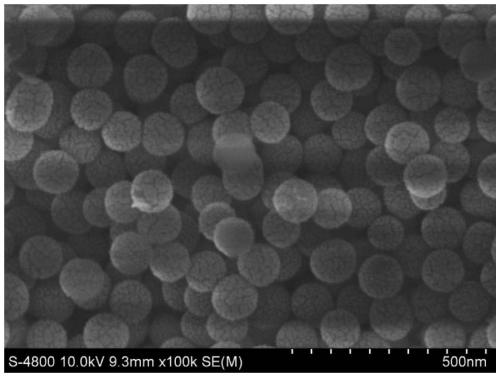

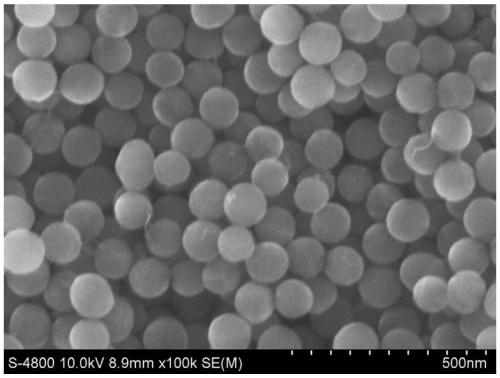

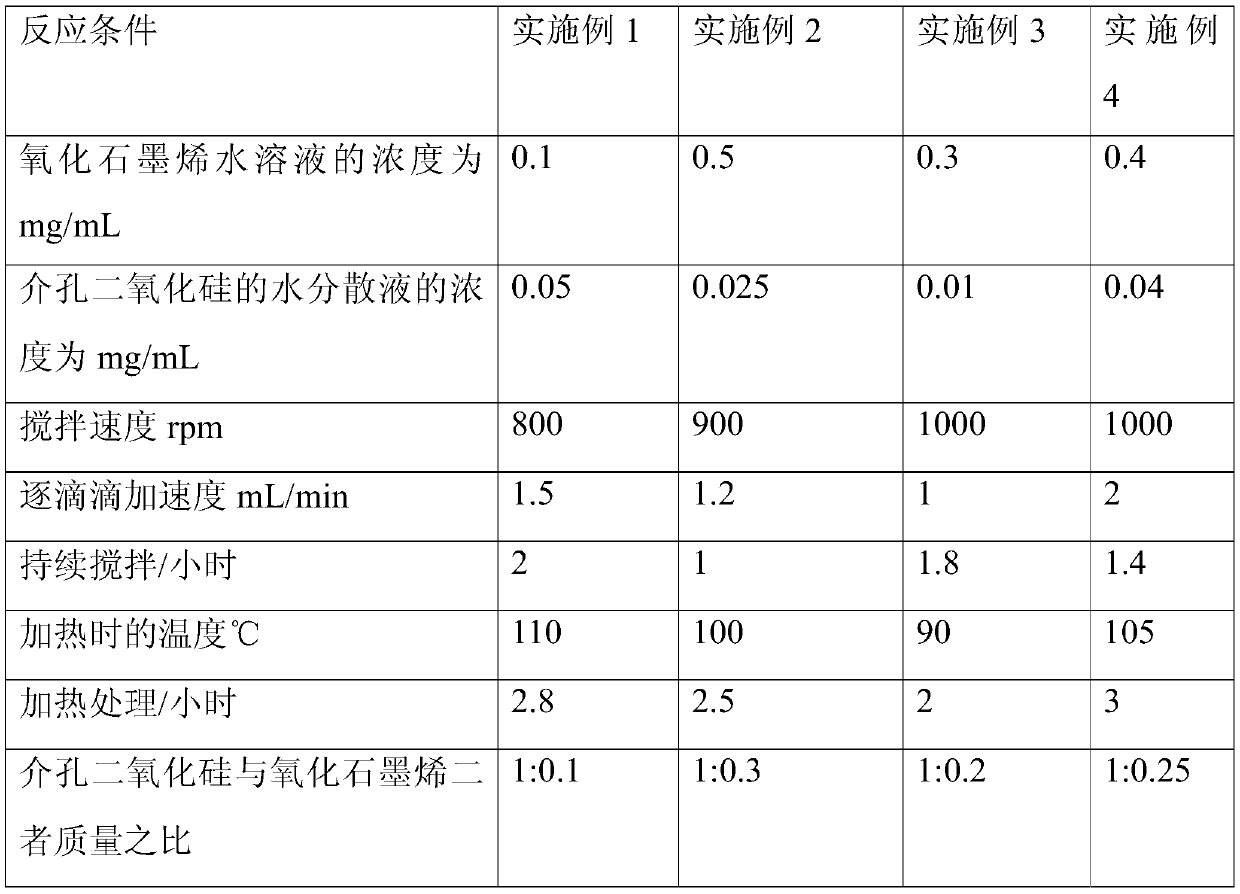

[0030] The invention provides a preparation method of core-shell type hierarchical porous structure nanoparticles. Under room temperature and strong stirring conditions, the graphene oxide aqueous solution is added dropwise to the water dispersion of mesoporous silica, and the stirring is continued. 1-2 hours, then heat treatment for 2-3 hours, and finally centrifuged and washed with ultrapure water to obtain a core-shell structure nanoparticle dispersion.

[0031] Strong stirring can promote the rapid dispersion of graphene oxide, while avoiding uneven coating of graphene oxide on the surface of mesoporous silica particles. Drop-by-drop addition can avoid too high concentration of local graphene oxide, thereby avoiding the disorder of its assembly on the surface of mesoporous silica particles.

[0032] Preferably, the concentration of the graphene oxide aqueous solution is 0.1-0.5 mg / mL, the concentration of the aqueous dispersion of mesoporous silica is 0.01-0.05 mg / mL; the ...

Embodiment 5-8

[0041] The present invention also provides a method for preparing a modified reverse osmosis membrane prepared from nanoparticles with a core-shell type hierarchical porous structure, comprising the following steps:

[0042] (1) configuring the core-shell type hierarchical porous structure nanoparticles into water phase and oil phase solutions respectively;

[0043] (2) Dry the polysulfone ultrafiltration membrane to a moisture content of 40-60%, then dip-coat the water phase solution on one side for 30-50s, and dry it to a moisture content of 60-80%, then continue to dip-coat the oil phase on the same side Solution, react for 55-65 seconds to make a composite membrane; one side is dipped in the water phase and then reacted with the oil phase, on the one hand, it can save raw materials, on the other hand, it can reduce the post-treatment steps of the reverse osmosis membrane;

[0044] (3) heat-treat the composite film at 40-50°C for 1-2 minutes, squeeze it with rubber rollers,...

Embodiment 9

[0054] Preparation of a modified reverse osmosis membrane prepared by core-shell type hierarchical porous nano-particles: Disperse mesoporous silica in ultrapure water and disperse with ultrasonic wave for 60 minutes to obtain a uniform dispersion with a concentration of 0.02mg / mL; disperse graphene oxide in ultrapure water, disperse and crush it with ultrasonic assistance for 3 hours, centrifuge and take the supernatant to obtain a graphene oxide solution with a concentration of 0.1mg / mL; at room temperature and under strong stirring conditions , the graphene oxide solution was added dropwise to the mesoporous silica dispersion, stirred continuously for 1 hour, then heated to 100°C for heat treatment for 3 hours, and finally centrifuged and washed. Configure the core-shell structure nanoparticles into a 0.03 mg / mL aqueous solution, add m-phenylenediamine to make the concentration respectively 2.35 (w / v)%; configure 0.99 (w / v)% trimesoyl chloride n-hexane solution; Dry the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com