Small flow control valve

A technology for controlling valve and small flow, applied in the direction of lift valve, valve detail, valve device, etc., to achieve the effect of large scaling factor, effective drive, and improved control accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

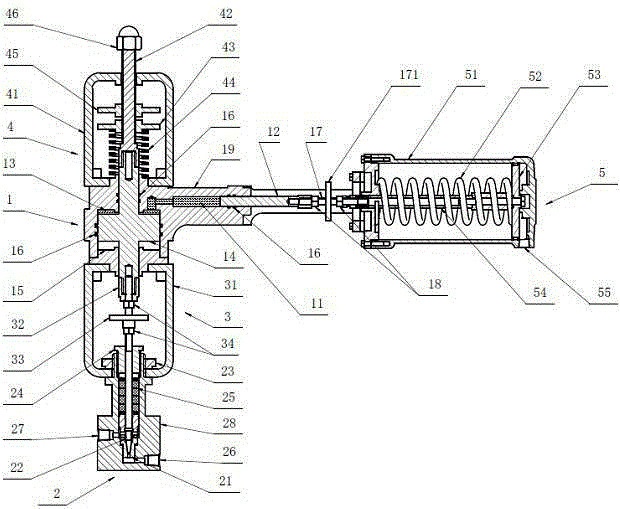

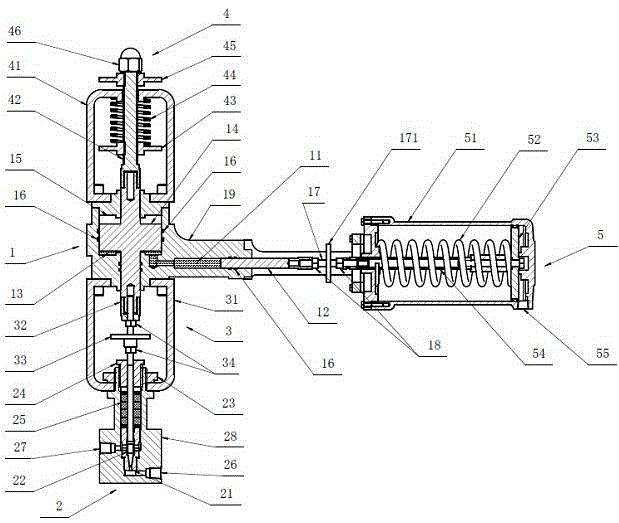

[0048] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

[0049] like figure 1 As shown, the small flow control valve of the present invention includes five parts: a hydraulic mechanism 1 , a reset device 4 , a valve connection device 3 , a valve 2 and an actuator 5 . The hydraulic mechanism 1 includes an integral frame 19, and two mutually perpendicular hydraulic cylinders are arranged in the integral frame 19, namely the active hydraulic cylinder 11 and the slave hydraulic cylinder 13, and the active hydraulic cylinder 11 and the slave hydraulic cylinder 13 respectively. They are connected by a channel inside the overall frame, the active piston 12 is arranged in the active hydraulic cylinder 11, and the driven piston 14 is arranged in the slave hydraulic cylinder 13; the whole frame cover is arranged at the open end of the slave hydraulic cylinder 15; The sectional area of the active hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com