Method for preparing titanium dioxide nanoflower electrode

A technology of titanium dioxide and nanoflowers, applied in the field of electrochemistry, can solve problems such as high cost, water pollution, and inability to use supercapacitor electrodes, and achieve the effect of simple steps and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

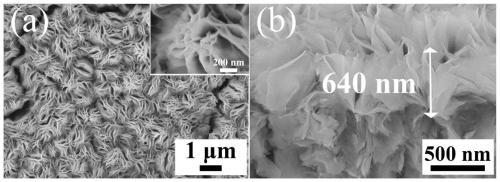

Embodiment 1

[0012] Firstly, a titanium foil with a purity of 99.5%, 6cm×1cm, and a thickness of 100μm is immersed in the polishing solution HF:HNO 3 :H 2 The oxide film on the surface of the titanium foil was removed by treatment in a mixed solution with a volume ratio of O of 1:1:2 for 15 s. Then rinse with deionized water, and finally dry naturally for later use. With the titanium foil as the anode and the graphite sheet as the cathode, the 4 F and 2vol%H 2 O in ethylene glycol electrolyte for constant voltage anodization. The anodizing voltage is 60V, the anodizing time is 5min, and the temperature of the electrolyte is kept at about 20°C. After anodizing, rinse with deionized water and dry naturally for later use.

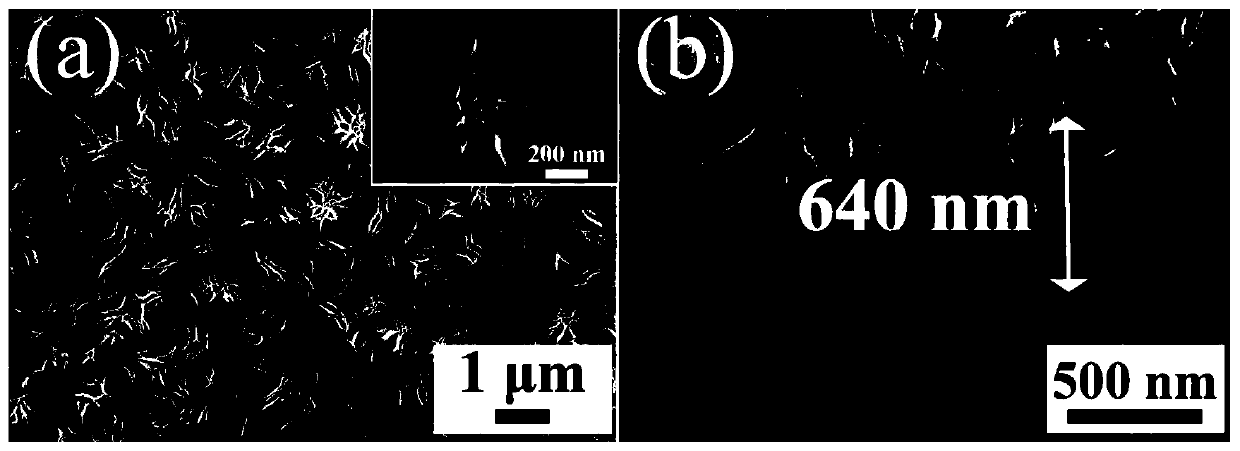

[0013] The anodized titanium foil is placed in a reaction kettle (50ml) with a polytetrafluoroethylene lining, and 15ml of 8wt% phosphoric acid aqueous solution is added to the polytetrafluoroethylene lining, and then the reaction kettle is placed at 75°C Treated in ...

Embodiment 2

[0015] The specifications, dimensions, pretreatment and anodizing process of the titanium foil are the same as in Example 1, the concentration of phosphoric acid is changed to 10 wt%, and the hydrothermal treatment process is the same as in Example 1. The prepared titanium dioxide nanoflowers are composed of petals with a height of about 670nm and a width of about 500nm.

Embodiment 3

[0017] The specification, size, pretreatment and anodic oxidation process of the titanium foil are the same as in Example 1, the concentration of phosphoric acid is changed to 12 wt%, and the hydrothermal treatment process is the same as in Example 1. The prepared titanium dioxide nanoflowers consist of petals with a height of about 690 nm and a width of about 450 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com