Ag(Ti,Zr)/rare earth crystalline silicon solar cell composite sizing agent and manufacturing method of Ag(Ti,Zr)/rare earth crystalline silicon solar cell composite sizing agent

A technology for solar cells and composite pastes, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of affecting the reliability of photovoltaic modules, increasing battery series resistance, and high power generation costs No inferior problems, to achieve the effect of enhancing electrode adhesion, reducing contact resistance, and improving battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

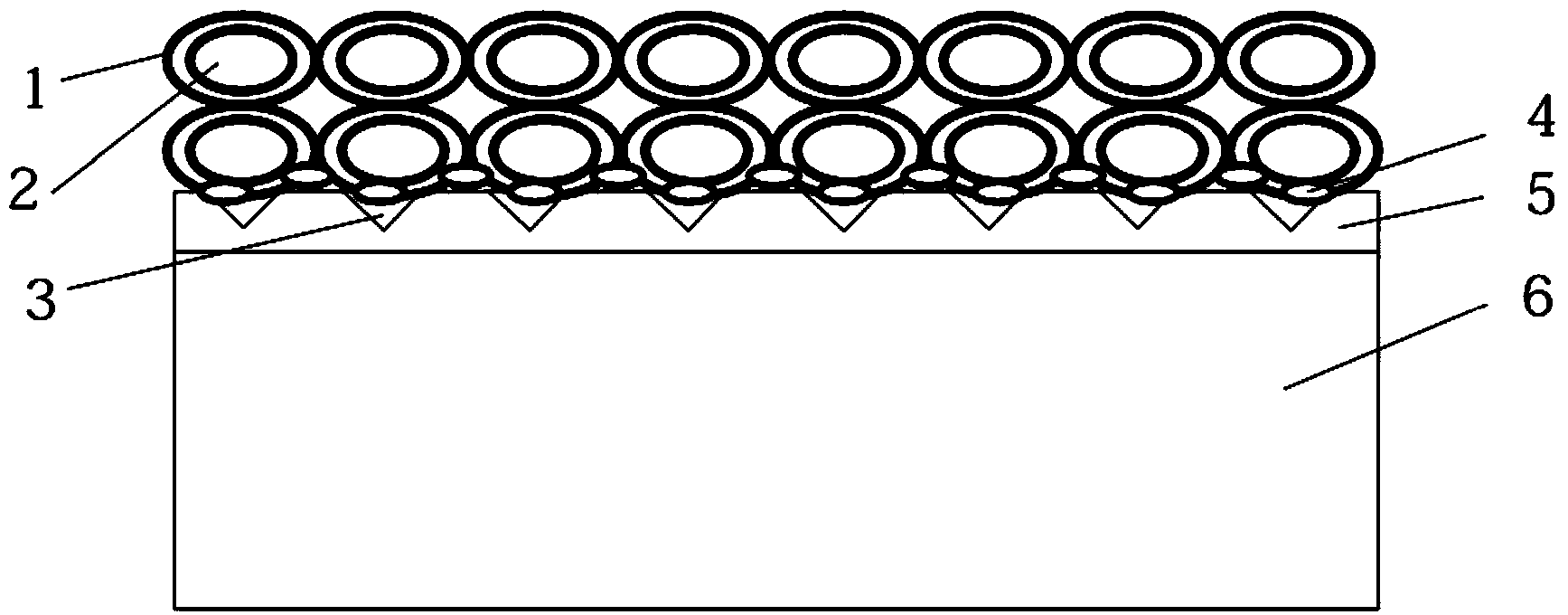

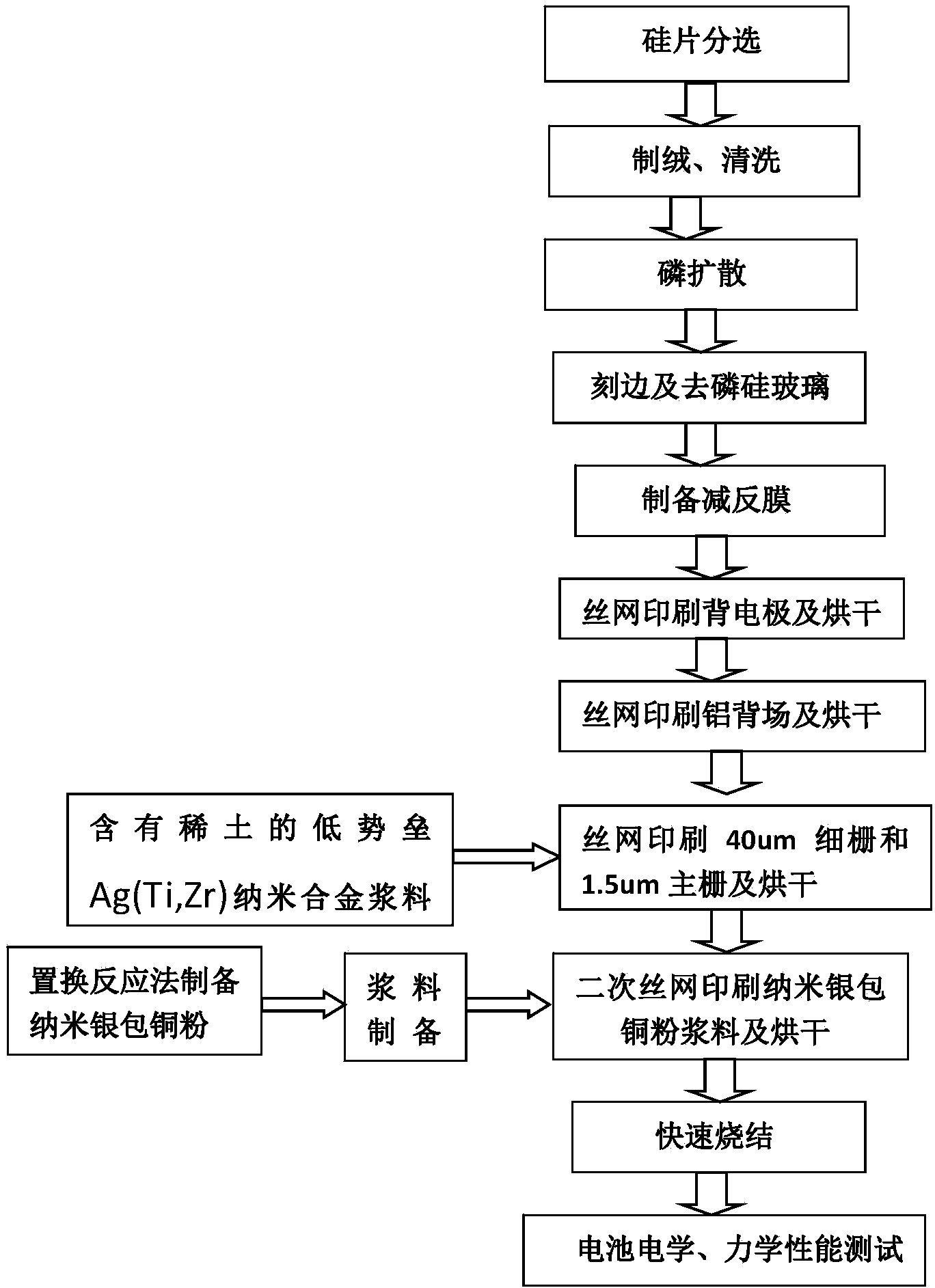

[0034] The invention provides an Ag(Ti, Zr) / rare earth crystalline silicon solar cell composite slurry and a preparation method thereof, which reduces the contact resistance of the crystalline silicon solar cell metallization system through a low contact barrier metal, and changes the slurry through a rare earth element The electrical and mechanical behavior of contact with silicon, through the copper powder coated with silver to form a macroscopic current-carrying channel. The advantage of the alloy paste is that it reduces the contact resistance between the screen printing silver paste and the silicon substrate, and enhances the electrode adhesion. At the same time, the silver-coated copper powder (copper-silver core-shell nanoparticle structure) reduces the consumption of metallic silver. Reduced battery cost.

[0035] The low contact barrier metals used in the present invention are Ti and Zr. The contact barrier formed between these metals and the solar cell emitter is rel...

Embodiment 1

[0048] A kind of Ag(Ti, Zr) / rare earth crystalline silicon solar cell composite slurry, by mass parts, including 0.1 part of glass binder, 7.8 parts of ultrafine silver powder, ultrafine TiO 2 Powder and Ultrafine ZrO 2 Powder mixture 0.5 part, Ce powder 0.1 part, organic binder 1 part and diluent 0.3 part.

[0049] The preparation method of the above-mentioned Ag(Ti,Zr) / rare earth crystalline silicon solar cell composite slurry comprises the following steps:

[0050] A: Preparation of glass binder

[0051] By mass percentage, 45% Bi 2 o 3 , 25% ZnO, 2% Al 2 o 3 , 25% of B 2 o 3 , 1% SiO 2 , 1% CaO and 1% TiO 2 Insulate in a high-temperature resistance furnace at 950°C for 90 minutes, then quench with deionized water, ball mill to 0.5-2um, and sieve through 200-400 mesh to obtain a glass binder;

[0052] B: Preparation of organic binder

[0053] In terms of parts by mass, mix 0.3 parts of ethyl cellulose, 1.0 parts of terpineol, 0.6 parts of vinyl alcohol, and 0.5 p...

Embodiment 2

[0056] A kind of Ag(Ti, Zr) / rare earth crystalline silicon solar cell composite slurry, by mass parts, including 0.25 parts of glass binder, 8 parts of ultrafine silver powder, ultrafine TiO 2 Powder and Ultrafine ZrO 2 Mixture of powders 0.4 parts, Eu powder 0.1 parts, organic binder 1.1 parts and diluent 0.4 parts.

[0057] The preparation method of the above-mentioned Ag(Ti,Zr) / rare earth crystalline silicon solar cell composite slurry comprises the following steps:

[0058] A: Preparation of glass binder

[0059] By mass percentage, 45% Bi 2 o 3 , 25% ZnO, 5% Al 2 o 3 , 21% of B 2 o 3 , 2% SiO 2 , 1% CaO and 1% TiO 2 Insulate in a high-temperature resistance furnace at 1000°C for 80 minutes, then quench with deionized water, ball mill to 0.5-2um, and sieve through 200-400 mesh to obtain a glass binder;

[0060] B: Preparation of organic binder

[0061] According to the number of parts by mass, mix 0.8 parts of ethyl cellulose, 0.5 parts of terpineol, 0.5 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com