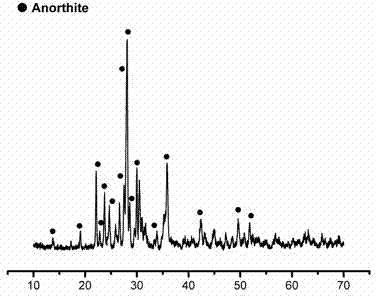

Preparation method of lightweight anorthite based thermal insulation material

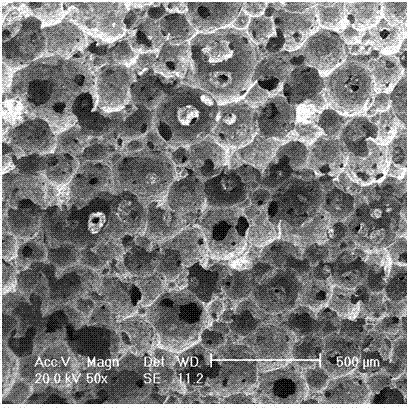

A thermal insulation material, light calcium technology, applied in the field of thermal insulation materials, can solve the problems of casualties, property, loss, etc., and achieve the effect of protecting the environment, high porosity, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 80 parts by mass of fly ash and 20 parts by mass of gypsum into the ball mill tank, add 0.8% sodium hexametaphosphate and 1.2% water glass (modulus 3.5), add an appropriate amount of water, and prepare a solid phase content of 30 % slurry, and ball milled for 24 h, the speed of the ball mill was 180 r / min. Add 0.8% sodium lauryl sulfate to water and foam for 4 min to obtain a uniform foam. Afterwards, mix the ball-milled slurry with foam, stir evenly with a stirrer, pour it into a gypsum abrasive tool, and let it stand for 4 hours before demoulding. After drying at room temperature for 24 h, the green body was dried in a drying oven at 100 °C for 24 h, and then sintered at 1100 °C. First, the temperature was raised to 500 °C at a rate of 2 °C / min and kept for 1 h; then the temperature was raised to 1100 °C at a rate of 5 °C / min and kept for 2 h; finally, the temperature was cooled to 500 °C at a rate of 5 °C / min; The furnace is cooled to room temperature to obtain...

Embodiment 2

[0030] Put 85 parts of fly ash and 15 parts of gypsum into the ball mill jar, add 0.8% gum arabic and 1.2% water glass, add an appropriate amount of water, prepare a slurry with a solid phase content of 30%, and ball mill for 24 h . Add 1.2% sodium lauryl sulfate to water and foam for 5 min to obtain a uniform foam. Afterwards, mix the ball-milled slurry with foam, stir evenly with a stirrer, pour it into a gypsum abrasive tool, and let it stand for 4 hours before demoulding. After drying at room temperature for 24 h, the green body was dried in a drying oven at 100 °C for 24 h, and then sintered at 1100 °C. First, the temperature was raised to 500 °C at a rate of 2 °C / min and kept for 1 h; then the temperature was raised to 1100 °C at a rate of 5 °C / min and kept for 2 h; finally, the temperature was cooled to 500 °C at a rate of 5 °C / min; The furnace is cooled to room temperature to obtain a lightweight anorthite-based insulation material.

[0031] The resulting lightweigh...

Embodiment 3

[0033] Add 80 parts of fly ash, 12 parts of limestone and 8 parts of waste glass powder into the ball mill jar, add 1.0% gum arabic and 1.0% water glass, add an appropriate amount of water, and prepare a slurry with a solid phase content of 35% material and ball milled for 24 h. Add 1.2% sodium lauryl sulfate to water and foam for 4 min to obtain a uniform foam. Afterwards, mix the ball-milled slurry with foam, stir evenly with a stirrer, pour it into a gypsum abrasive tool, and let it stand for 4 hours before demoulding. After drying at room temperature for 24 h, the green body was dried in a drying oven at 100 °C for 24 h, and then sintered at 1100 °C. First, the temperature was raised to 500 °C at a rate of 2 °C / min and kept for 1 h; then the temperature was raised to 1100 °C at a rate of 5 °C / min and kept for 2 h; finally, the temperature was cooled to 500 °C at a rate of 5 °C / min; The furnace is cooled to room temperature to obtain a lightweight anorthite-based insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com