Heat-pipe-type alkali-metal vapor laser device

A technology of alkali metals and lasers, which is applied to lasers, laser parts, laser parts, etc., can solve problems such as alkali metal vapor condensation, and achieve the effects of uniform gain distribution, high thermal conductivity, and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

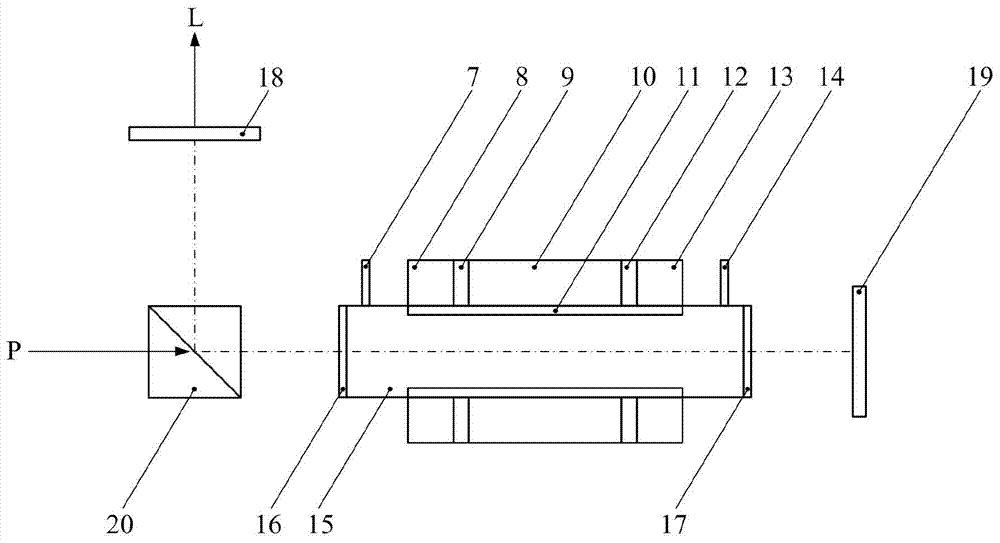

[0023] Specific implementation mode one: as figure 2 Shown, a heat pipe type alkali metal vapor laser, including a gain unit and a resonant cavity.

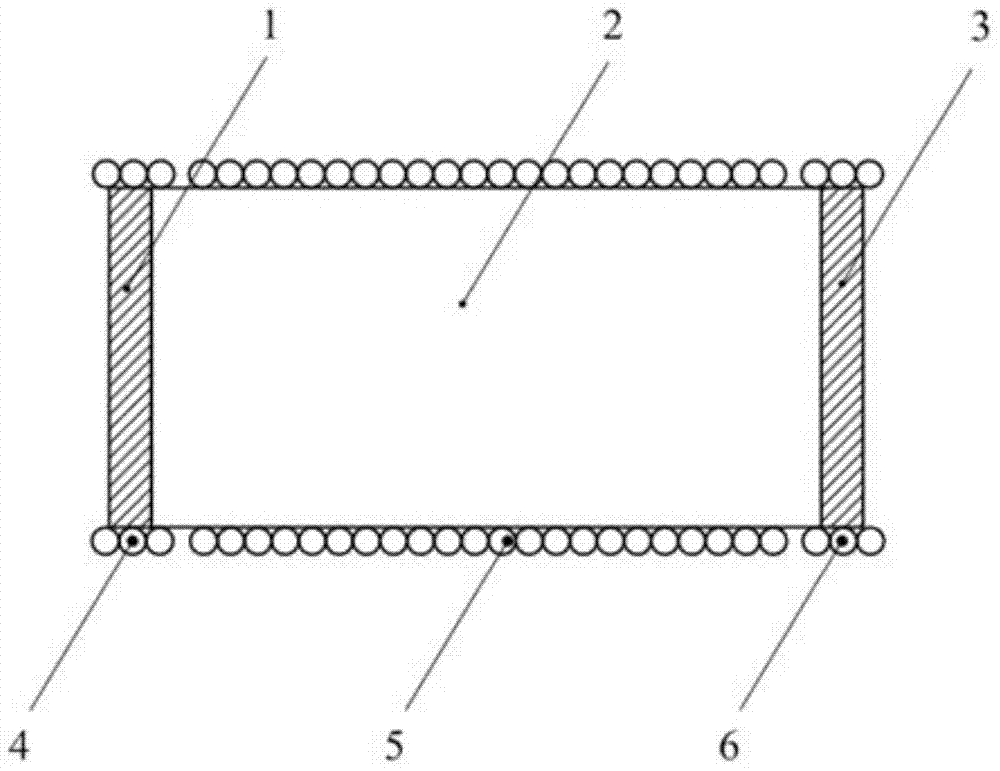

[0024] The gain unit is a heat pipe structure, including a tube shell 15, a left window 16, a right window 17, a heater 10, a left cooler 8, a right cooler 13, a liquid-absorbing core 11, a left insulating material layer 9, and a right insulating material layer 12. The left inflation port 7 and the right inflation port 14. The heater 10 , the right refrigerator 13 , the liquid-absorbing core 11 , the left heat-insulating material layer 9 and the right heat-insulating material layer 12 are all ring-shaped structures sleeved on the tube shell 15 .

[0025] The tube shell 15 is made of stainless steel, which is compatible with the alkali metal vapor, that is, during the operation of the laser, the alkali metal vapor and the tube shell 15 will not undergo significant chemical reactions or physical changes. The left window 16 and t...

Embodiment approach 2

[0029] Implementation mode two: if image 3 As shown, on the basis of Embodiment 1, in order to reduce the intracavity loss of the laser, a Brewster window is applied to the gain unit, and the left window 21 and the right window 22 at both ends of the tube shell 15 are Brewster windows , forming an angle with the optical axis of the laser resonator. In this way, the linearly polarized light oscillating in the resonant cavity will pass through the left and right windows without reflection loss, thereby reducing the loss in the cavity.

[0030]Taking the rubidium vapor laser medium as an example, the specific working process of the heat pipe type external cavity alkali metal vapor laser described in Embodiment 2 is as follows: the temperature of the heater is set at a temperature higher than the melting point of rubidium (39.3°C), and the temperature is set to refrigerate. The temperature of the device is set at a certain temperature below the melting point of rubidium. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com