A method for processing copper scum

A technology of copper scum and water slag, which is applied in the field of metallurgy, can solve the problems of high energy consumption, high processing costs, and low production efficiency in smelting, and achieve the effects of high metal direct recovery rate, high recovery rate, and high smelting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

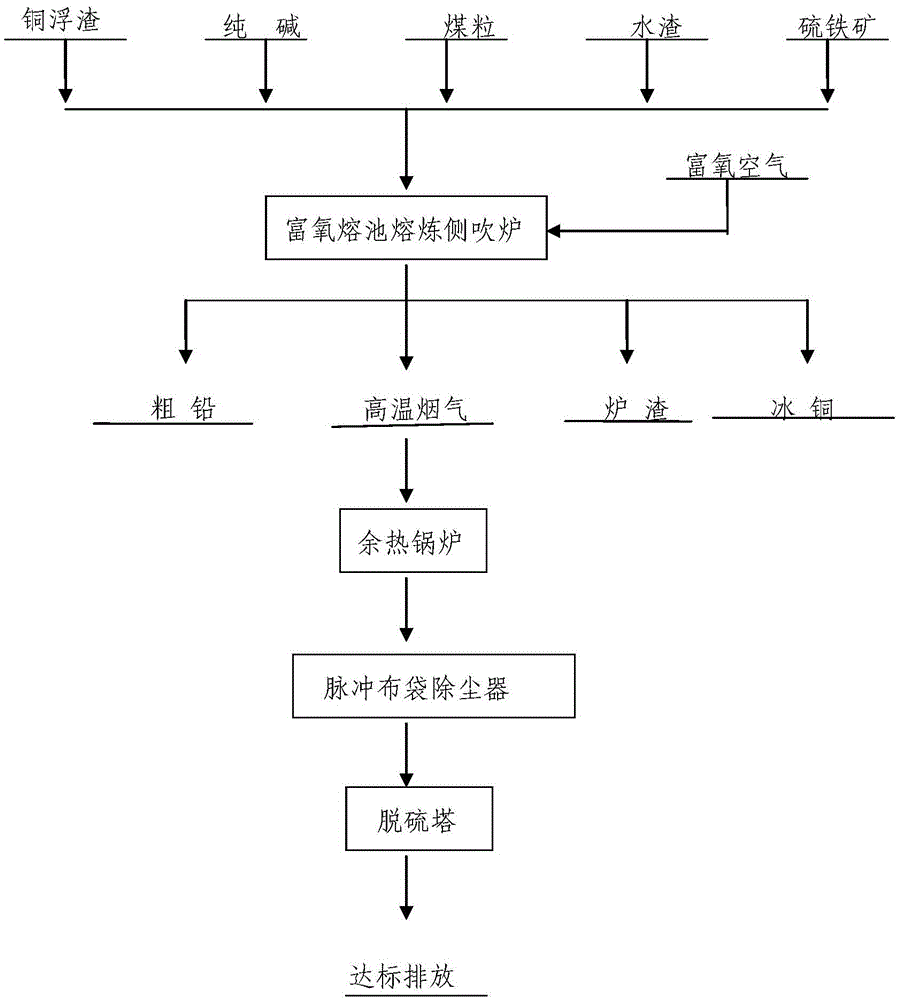

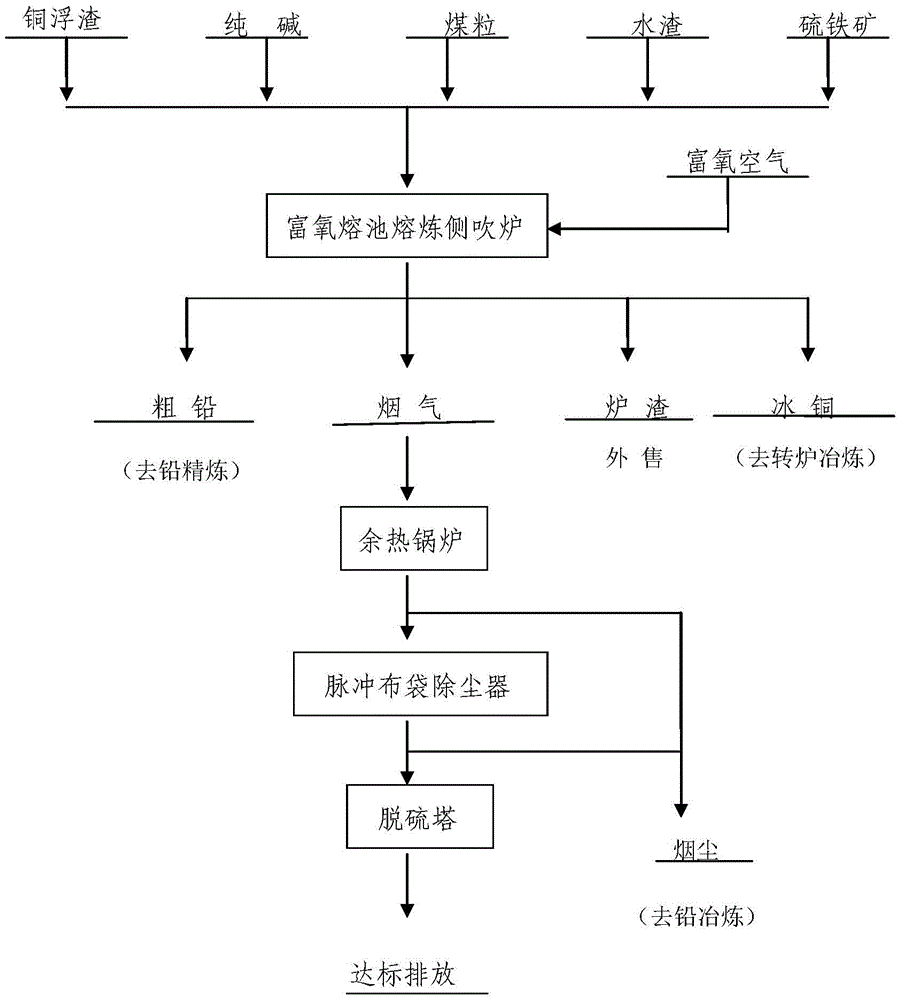

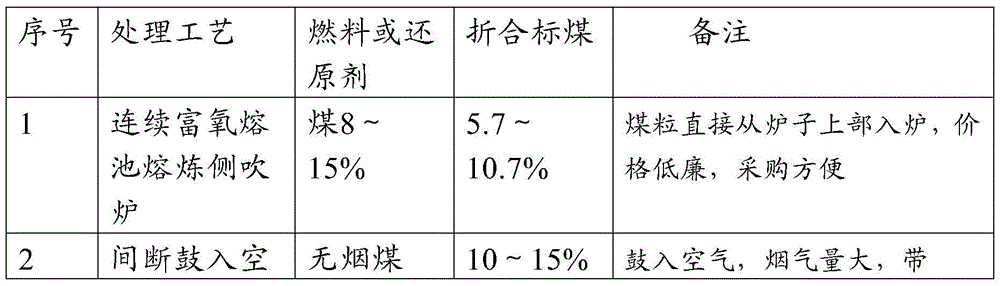

[0037] Such as figure 1 shown at 6m 2 In the oxygen-enriched molten pool smelting side-blown furnace, copper scum (Pb72%, Cu8.1%), soda ash, pyrite (S32%), water slag, according to the mass ratio of 100:3:6:12 Do batching, feed for 3 hours, a total of 60t, at the same time unload 6.6t of coal from the feeding port, and blow in 2300Nm of oxygen-enriched air 3 / h, the oxygen concentration is 51%.

[0038] Crude lead is released through the lead siphon, and 33.6t of crude lead (containing 97.5% lead, Cu0.4%) is produced. The crude lead produced needs to be deleaded and refined; matte (containing 5.4% lead, Cu0.4%) is produced through the matte port Cu43%) 8.4t, the produced matte is smelted in the converter; 11.7t of slag (containing 1.4% lead, Cu0.28%) is released through the slag outlet, and the slag is used for external sale; high-temperature flue gas recovers waste heat through the waste heat boiler , after dust collection by pulse, desulfurization by desulfurization tower...

Embodiment 2

[0041] Such as figure 1 shown at 6m 2 In the side-blown furnace, copper scum (Pb72%, Cu8.1%), soda ash, pyrite (S32%), and water slag are mixed according to the ratio of mass ratio 100:3:5:8, and the feeding time is 4 hours. , a total of 80t. At the same time, 8.8t of coal is discharged from the discharge port, and 2500Nm of oxygen-enriched air is blown in 3 / h, the oxygen concentration is 54%.

[0042] Crude lead is released through the lead siphon channel, producing 47.3t crude lead (containing 97.5% lead, Cu0.4%), 8.3t soot, 12.1t slag (containing 1.3% lead, Cu0.25%), and matte copper (containing lead 5.1%, Cu46%) 11.7t, lead yield 92.9%, recovery rate 99.7%, copper recovery rate 92.2%, copper matte Cu / Pb ratio 9.02.

Embodiment 3

[0044] Such as figure 1 shown at 6m 2 In the side-blown furnace, copper scum (Pb57%, Cu10.2%), soda ash, pyrite (S32%), and water slag are mixed according to the mass ratio of 100:2:8:8, and the feeding is 4h , a total of 48t. At the same time, 3.8t of coal is discharged from the discharge port, and 2300Nm of oxygen-enriched air is blown in. 3 / h, the oxygen concentration is 56%.

[0045] Crude lead is released through the lead siphon channel, producing 21.6t crude lead (containing 97.5% lead, Cu0.4%), 4.9t soot, 13.5t slag (containing 1.2% lead, Cu0.24%), and matte copper (containing lead 5.2%, Cu48%) 7.7t, lead yield 93.1%, recovery rate 99.3%, copper recovery rate 89.1%, copper matte Cu / Pb ratio 9.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com