A kind of high temperature thermal aging basalt fiber reinforced polybutylene terephthalate composite material and its preparation method

A polybutylene terephthalate and basalt fiber technology, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of less research on basalt fiber, the difficulty of surface infiltration treatment of basalt fiber, and the inability to effectively solve the problem of basalt fiber and PBT. Resin surface binding problems and other problems, to achieve the effect of improving chemical force and interfacial adhesion, improving compatibility and bonding strength, and excellent high temperature and thermal aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

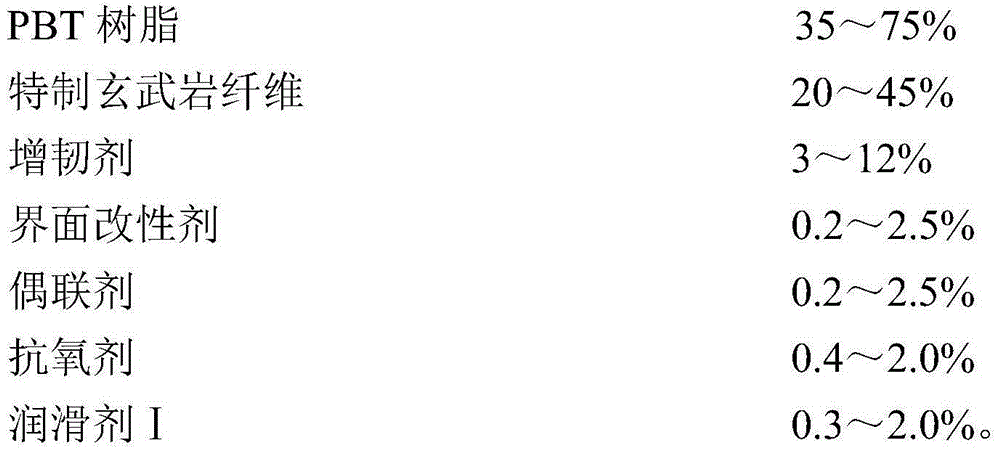

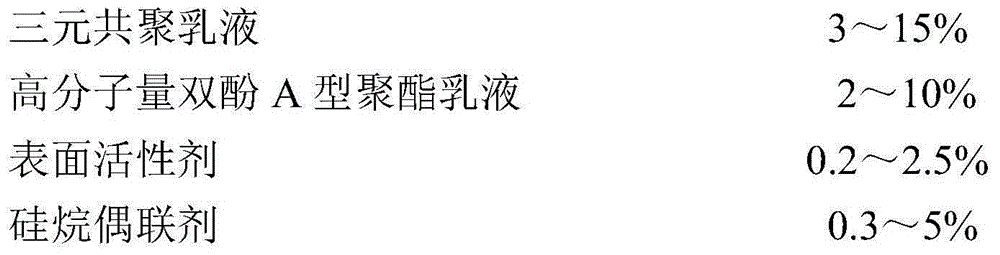

Method used

Image

Examples

Embodiment 1- Embodiment 6

[0083] Weigh the PBT resin and other raw materials according to the weight ratio, add the PBT resin, interface modifier and coupling agent to the high-speed mixer (rotating at 475RPM), and mix for 30 seconds; then add the toughening agent, antioxidant and Lubricant I was added and mixing continued for 60 seconds.

[0084] The mixed raw materials are added to the twin-screw extruder, and the special basalt fiber is added through the fiberizing port, melted and extruded, cooled and pelletized to obtain a composite material.

[0085] The processing temperature of the extruder is set to 230°C for zone 1, 230°C for zone 2, 235°C for zone 3, 235°C for zone 4, 235°C for zone 5, 240°C for zone 6, 240°C for zone 7, and 240°C for zone 8. Zone temperature 240°C, die temperature 245°C.

[0086] The material was dried in a blast drying oven at 120°C for 6 hours and then injection molded to prepare test specimens.

[0087] Comparative example 1

[0088] Weigh the PBT resin and other raw ...

Embodiment 4

[0110] The tensile strength of Example 4 (basalt fiber reinforced PBT composite material) before the high temperature thermal aging test is 149MPa, the flexural modulus is 8320MPa, and the notched Charpy impact strength is 12.2kJ / m 2 and unnotched Charpy impact strength 53.6kJ / m 2 , the comprehensive performance of the above is better than that of Comparative Example 1 (glass fiber reinforced PBT composite material).

[0111] Example 4 (basalt fiber reinforced PBT composite material) has outstanding impact toughness and mechanical properties after passing the UL746B standard thermal aging test. Tensile strength 138MPa, flexural modulus 7750MPa, notched Charpy impact strength 9.7kJ / m 2 and unnotched Charpy impact strength 39.5kJ / m 2 . The thermal aging retention rate of tensile strength is 92.6%, the thermal aging retention rate of flexural modulus is 93%, the thermal aging retention rate of notched Charpy impact strength is 79.5%, and the thermal aging retention rate of unn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com