Preparation method of low-temperature sintering high-tunability barium strontium titanate ceramic

A technology of barium strontium titanate and low temperature sintering is applied in the field of preparation technology of new microwave tuning materials, which can solve the problems of lowering the dielectric constant of materials and decreasing the dielectric tuning rate, so as to improve the dielectric properties, reduce the sintering temperature, and reduce the production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

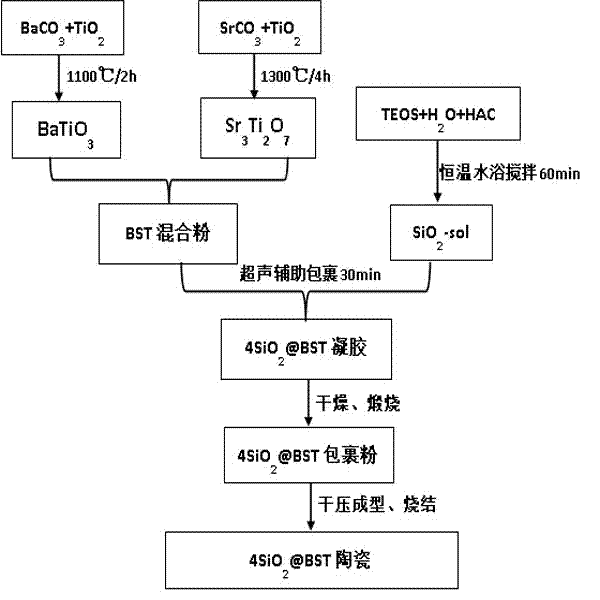

[0027] Specific steps are as follows:

[0028] A. BST4wt%SiO 2 preparation

[0029] (1) 80wt%BaTiO 3 -20wt%Sr 3 Ti 2 o 7 (BST) Preparation of mixed powder

[0030] To analyze pure BaCO 3 , SrCO 3 、TiO 2 Raw material, according to BaTiO 3 and Sr 3 Ti 2 o 7 Required stoichiometric ratio Weigh the above-mentioned raw materials and put them into corresponding ball milling tanks, then add an appropriate amount of deionized water, absolute ethanol and ball milling media whose weight is 0.8-1.5 times the weight of the raw materials, and mill for 24 hours. Pour the two kinds of ball milling slurries into clean porcelain plates, place them in a constant temperature oven at 120°C for drying, then grind the powders and sieve them, and then add a small amount of deionized water to the two fine powders respectively. Stir to form a semi-dry powder, press it into a disc and put it into a crucible, and place it in a sintering furnace for 2 hours at 1100°C and 1300°C for 4 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com