Preparation method of transparent nickel oxide film varactor

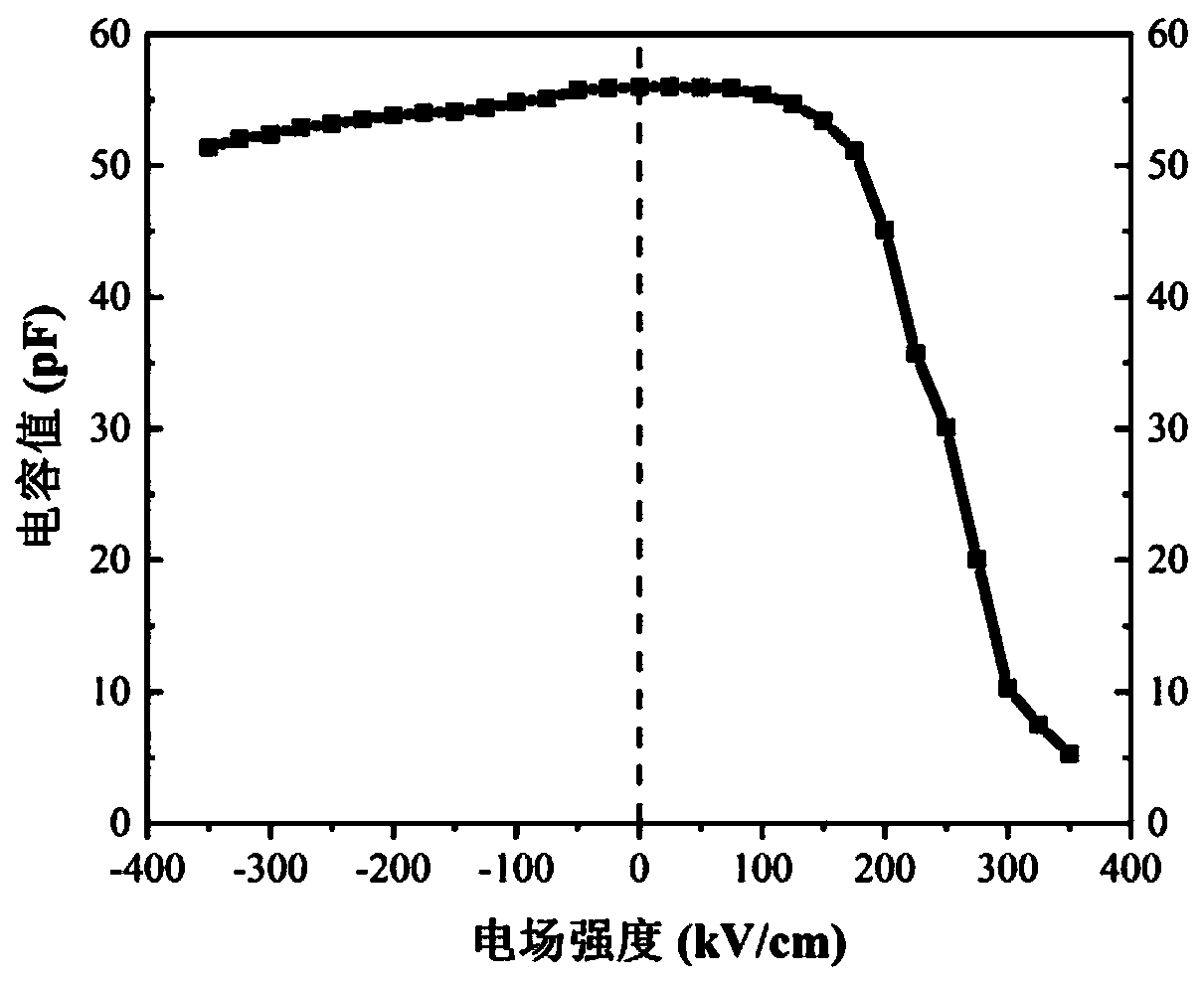

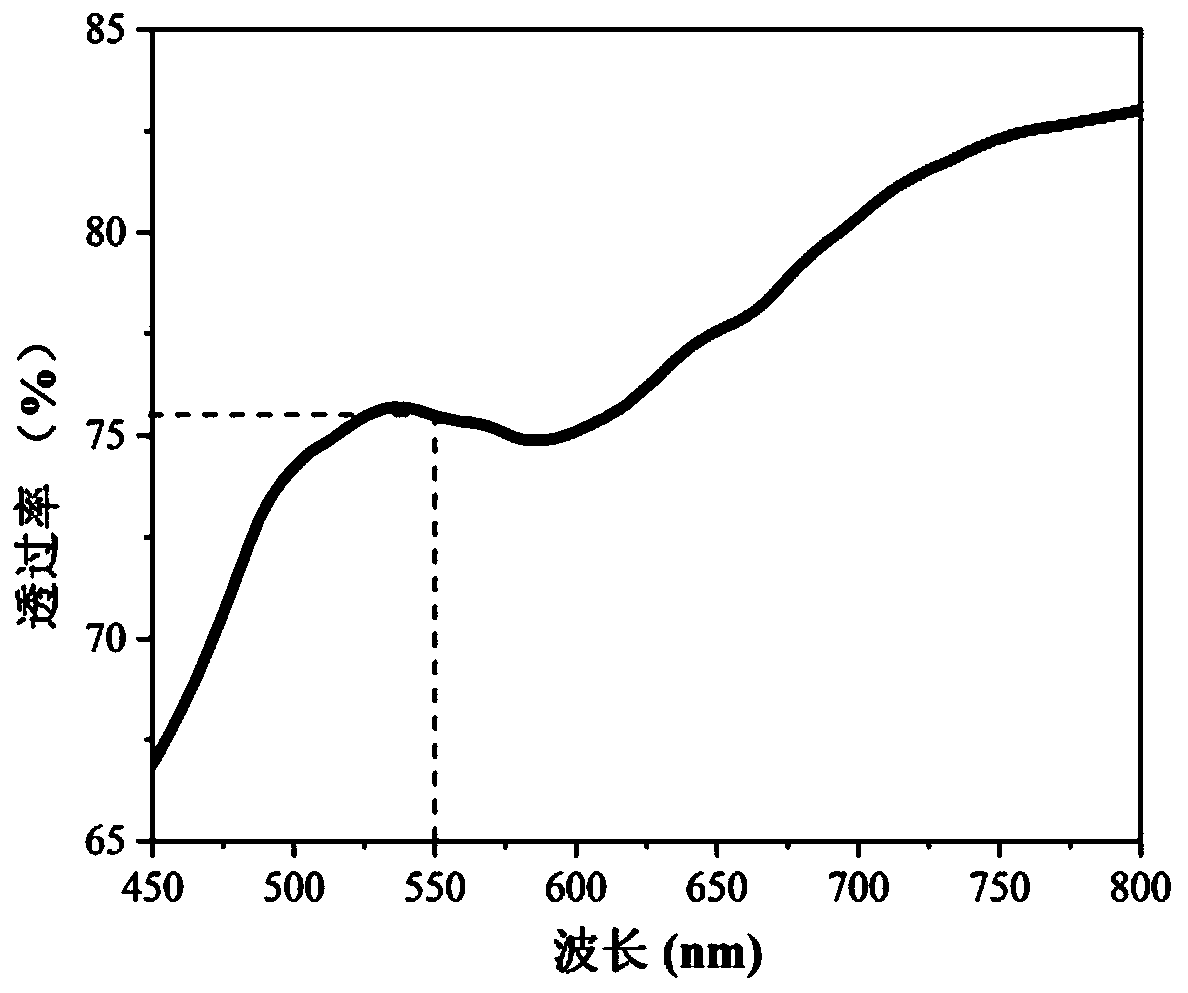

A transparent oxidation and varactor technology, which is applied in capacitor manufacturing, variable voltage capacitors, capacitors, etc., can solve the problem that the transparency of varactors is only 60%, and achieve excellent visible light transmittance, high tuning rate, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Clean the substrate

[0034] Put the ITO conductive glass substrate attached on the surface into acetone and alcohol to ultrasonically clean it for 15 minutes respectively, rinse it with deionized water and dry it in nitrogen flow;

[0035] (2) Preparation of NiO thin film

[0036] (a) put the dried ITO conductive glass substrate of step (1) on the magnetron sputtering sample stage, install the purchased metal Ni target material on the corresponding DC sputtering target, and the purity of the metal NiO target material is greater than 99.99%, the background vacuum of the magnetron sputtering system is pumped to 6.0×10 -6 Torr, then turn on the substrate heating and set it to 500°C;

[0037] (b) Using high-purity Ar and O2 as sputtering gases, O 2 : Ar=3:1, the sputtering pressure is 10mTorr, the sputtering power is 140W, a NiO film with a thickness of 200nm is deposited on ITO, and its thickness can be controlled by adjusting time, air pressure, oxygen-argon ratio...

Embodiment 2

[0048] The post-annealing temperature of NiO in Example 2 is 600° C., the annealing time is 10 min, and other process steps and process parameters are the same as those in the example.

[0049] It is tested that the tuning rate of the NiO varactor in Example 2 is 82.3% at positive bias, 10.4% at negative bias, and 72.4% at light transmittance.

Embodiment 3

[0051] The thickness of NiO in Example 3 is 100 nm, and other process steps and process parameters are the same as those in Example 3.

[0052] It is tested that the tuning rate of the NiO varactor in Example 3 is 88.5% at positive bias, 11.6% at negative bias, and 79.5% at light transmittance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com