Anti-solvent vinyl polymer with multilayer structure, synthetic method thereof and applications thereof

A vinyl polymer and synthesis method technology, applied in the field of printing, can solve the problems of poor solvent resistance and printing resistance, large developing latitude, etc., and achieve strong printing resistance, large developing latitude, and good storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

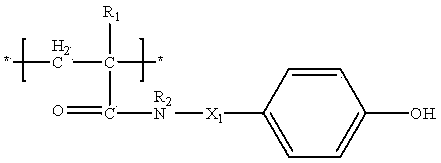

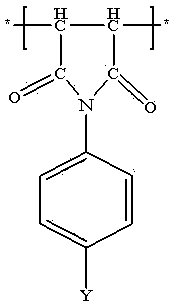

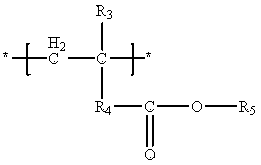

Method used

Image

Examples

Embodiment 1

[0034] Example 1 (emulsion particles 01)

[0035] Add 250 g of isopropanol, 150 g of deionized water, 25 g of N, N-dimethylformamide, 15 g of methyl acrylate, and 5 g of dioctylsuccinate into a 1000 ml three-necked flask equipped with a stirrer, a reflux tube, and a dropping funnel. Acid sodium, 1.2 g AIBN (azobisisobutyronitrile), stir evenly, and use a hot water bath to heat to 80 ° C, dropwise add 29 g of N- (4-acetoxyphenyl) maleimide, 25 g of 3- Acrylonitrile, 6 g of methacrylic acid, 0.8 g of AIBN (azobisisobutyronitrile) were dissolved in a mixed solution of 250 g of isopropanol, and the addition was completed dropwise in 2 hours. The reaction was completed after 10 hours at constant temperature.

[0036] The solid content is 18.3%, the weight average molecular weight is 25000, and the number average molecular weight is 2500.

Embodiment 2

[0037] Example 2 (emulsion particles 02)

[0038] Add 250 g of isopropanol, 150 g of deionized water, 15 g of N,N-dimethylformamide, 20 g of methyl acrylate, and 5 g of dioctylsuccinate into a 1000 ml three-necked flask equipped with a stirrer, a reflux tube, and a dropping funnel. Acid sodium, 1.2 g AIBN (azobisisobutyronitrile), stir evenly, and use a hot water bath to heat to 80 ° C, dropwise add 31 g of N-(4-sulfonamidobenzene) maleimide, 30 g of 3- Acrylonitrile, 4 g of methacrylic acid, 0.8 g of AIBN (azobisisobutyronitrile) were dissolved in a mixed solution of 250 g of isopropanol, and the addition was completed dropwise in 1.5 hours. The reaction was completed after 9 hours at constant temperature.

[0039] The solid content is 16.1%, the weight average molecular weight is 32000, and the number average molecular weight is 2300.

Embodiment 3

[0040] Example 3 (emulsion particles 03)

[0041]In a 1000ml three-necked flask equipped with a stirrer, a reflux tube, and a dropping funnel, add 250 g of isopropanol, 150 g of deionized water, 30 g of N-(4-hydroxybenzene) methacrylamide, 10 g of methyl acrylate, 5 g Dioctyl sodium succinate, 1.2 g AIBN (azobisisobutyronitrile), stir evenly, and use a hot water bath to heat to 80 ° C, dropwise add 25 g N-(4-acetoxyphenyl) maleimide Amine, 30g of acrylonitrile, 5g of methacrylic acid, and 0.8g of AIBN (azobisisobutyronitrile) were dissolved in a mixed solution of 250g of isopropanol, and the addition was completed dropwise in 2 hours. The reaction was completed after 10 hours at constant temperature.

[0042] The solid content is 14.2%, the weight average molecular weight is 30000, and the number average molecular weight is 2100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com