Composite nano-metal materials and methods prepared by combining with ordered porous supports or rough surfaces

A porous carrier and nano-metal technology, which is applied in the field of nano-materials, can solve the problems of difficult release of nano-metal particles, and achieve excellent surface Raman enhancement performance, uniform particle size, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

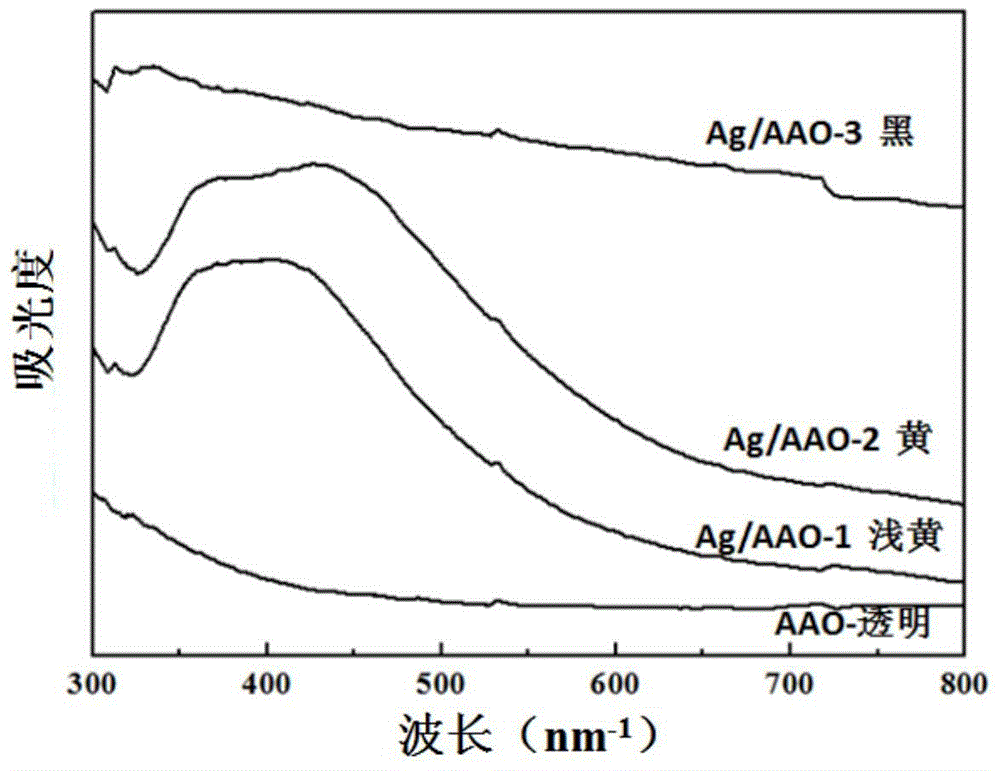

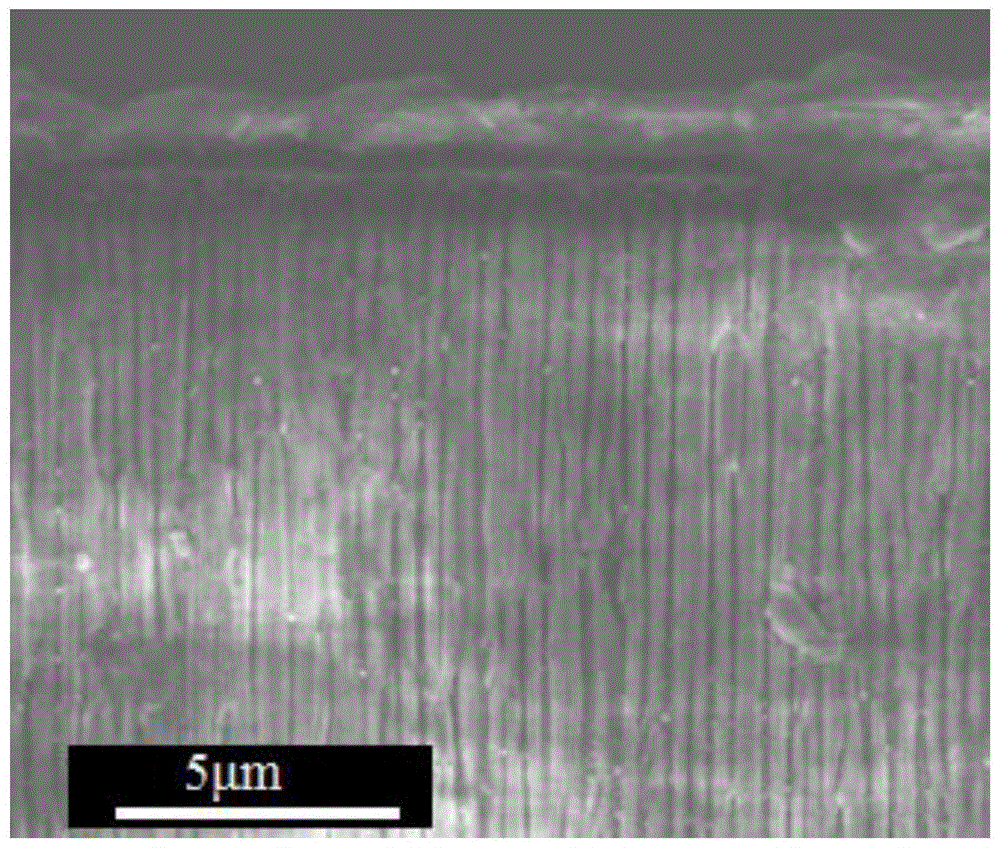

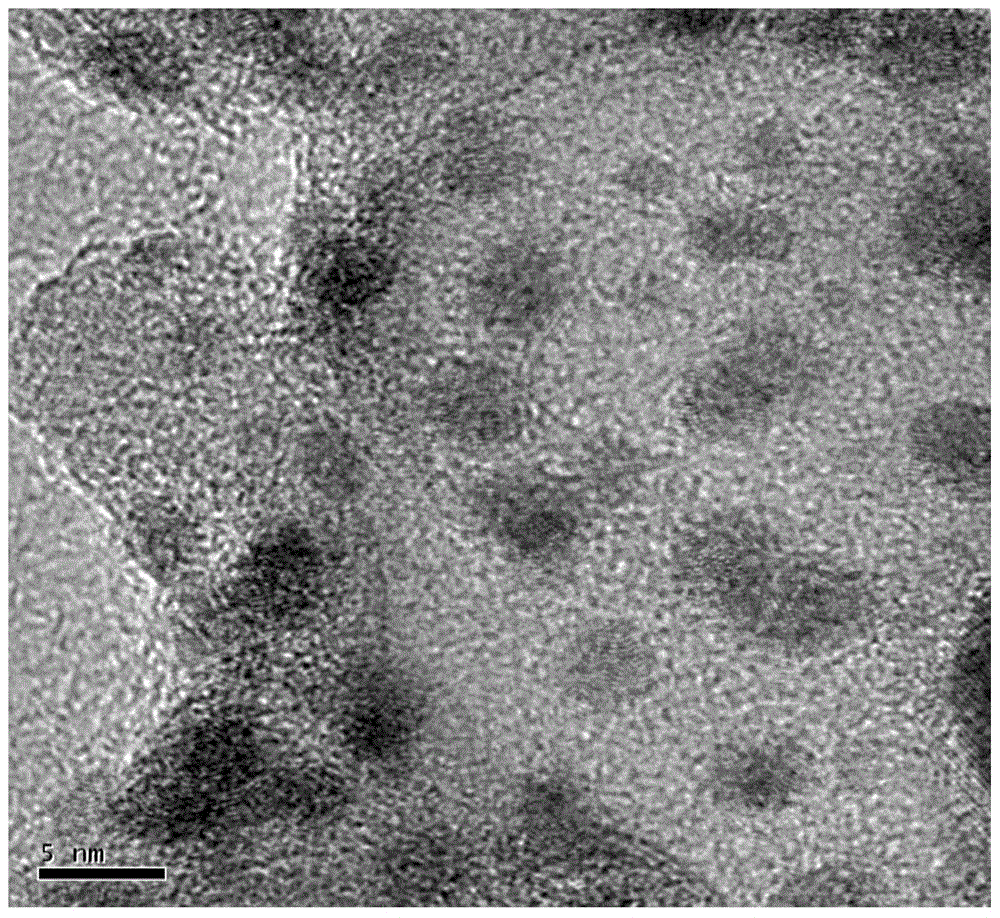

Embodiment 1

[0049] 0.005mol / L silver nitrate (AgNO 3 ) solution is sprayed on the porous alumina carrier, placed between the two electrode plates of the plasma, sealed, the vacuum chamber is evacuated, and then filled with argon as the discharge gas, maintaining a pressure of 200Pa, and applying 300V on the electrode AC voltage, reduction of AgNO using glow discharge plasma 3 , the plasma temperature is 50°C, and the reduction time is 3min. This process can be repeated different times to prepare nano-metal particle aggregates with different sizes and loads. The nano-metal particles of the sample are combined with the pores of the porous carrier to form a photonic crystal structure that is periodically arranged in an orderly manner. When the incident light is irradiated from different angles, it will show different colors. At the same time, the surface of the porous carrier roughened by the nano-metal particles It has excellent surface Raman enhancement performance, and the Raman enhance...

Embodiment 2

[0056] 0.001mol / L chloroauric acid (HAuCl 4 ) solution is sprayed on the porous alumina carrier, then placed between the two electrode plates of the plasma discharger, sealed, the vacuum chamber is evacuated, and then filled with air as the discharge gas, maintaining a pressure of 200Pa, applying A DC voltage of 500 V was used to reduce chloroauric acid (HAuCl 4 ), the temperature of the plasma is 25°C, and the reduction time is 5min, and uniform gold metal particle accumulations are prepared. This process can be repeated different times to prepare nano-metal particle aggregates with different sizes and loads. The nano-metal particles of the sample are combined with the pores of the porous carrier to form a photonic crystal structure that is periodically arranged in an orderly manner. When the incident light is irradiated from different angles, it will show different colors. At the same time, the surface of the porous carrier roughened by the nano-metal particles It has exce...

Embodiment 3

[0061] 0.005mol / L chloroauric acid (HAuCl 4 ) and the same concentration of palladium nitrate (Pd(NO 3 ) 2 ) The mixed solution is sprayed on the porous alumina, then placed between the two electrode plates of the plasma, sealed, the vacuum chamber is evacuated, and then filled with argon as the discharge gas, maintaining a pressure of 500Pa, and applying 800V on the electrode AC voltage of HAuCl reduction by glow discharge plasma 4 and Pd(NO 3 ) 2 , the plasma temperature is 100°C, and the reduction time is 5min. Chlorauric acid (HAuCl 4 ) solution and palladium nitrate (Pd(NO 3 ) 2 ) mixed solution was sprayed on the sample, and then spraying and plasma treatment were repeated 9 times under the same conditions to prepare gold-palladium alloy nano-metal particle agglomerates. The nano-metal particles of the sample are combined with the pores of the porous carrier to form a periodic and ordered photonic crystal structure, which will show different colors when the incid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com