Method and device for preparing coating by using nanosecond pulse laser cladding

A nanosecond pulsed laser and coating technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve problems such as affecting the surface quality of the cladding layer, shrinking the film into molten droplets, and discontinuous heat conduction. , to achieve the effect of shortening the production cycle, good film quality and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Preparation before cladding. Open the vacuum chamber and place the aluminum workpiece on the sample stage, close the quartz vacuum chamber, and turn on the vacuum pump to evacuate the quartz vacuum chamber until the vacuum degree reaches the order of 1Pa.

[0058] 2. Heating the workpiece. Turn on the induction heating coil to heat the workpiece until the temperature displayed by the thermocouple reaches 165°C, and maintain a constant temperature.

[0059] 3. Laser cleaning the surface of the workpiece. Turn on the laser scanning system to clean the surface of the workpiece by nanosecond pulse laser sputtering, the energy density of the nanosecond pulse laser is 1000 mJ / cm 2 , the overlap rate is 30%, and then turn off the laser scanning system.

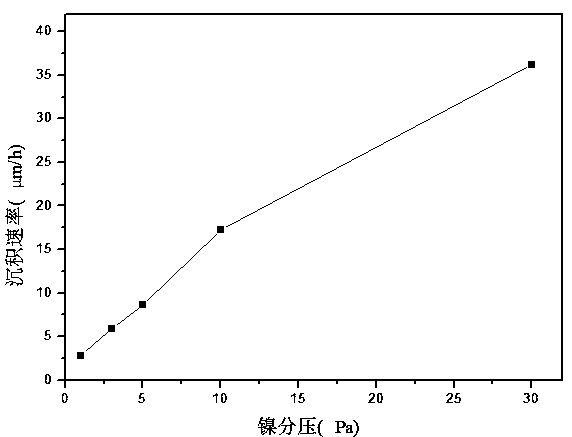

[0060] 4. Laser cladding. Open the valve, let the argon enter the nickel carbonyl source tank through the mass flow meter, load the carbonyl nickel into the quartz vacuum chamber, adjust the flow rate of the argon, and ...

Embodiment 2

[0063] 1. Preparation before cladding. Open the vacuum chamber, place the uranium workpiece on the sample stage, close the vacuum chamber, turn on the vacuum pump, and evacuate the vacuum chamber until the vacuum degree reaches the order of 1Pa.

[0064] 2. Heating the workpiece. Turn on the induction heating coil to heat the workpiece until the temperature displayed by the thermocouple reaches 165°C, and maintain a constant temperature.

[0065] 3. Laser cleaning the surface of the workpiece. Turn on the laser scanning system to clean the surface of the workpiece by nanosecond pulse laser sputtering, the energy density of the nanosecond pulse laser is 1000 mJ / cm 2 , the overlap rate is 30%, and then turn off the laser scanning system.

[0066] 4. Laser cladding. Open the valve, let the argon enter the nickel carbonyl source tank through the mass flow meter, load the carbonyl nickel into the vacuum chamber, adjust the flow rate of the argon, and make the partial pressure o...

Embodiment 3

[0070] 1. Preparation before cladding. Open the vacuum chamber, place the ceramic workpiece on the metal sample stage, close the vacuum chamber, turn on the vacuum pump, and evacuate the vacuum chamber until the vacuum degree reaches the order of 1Pa.

[0071] 2. Heating the workpiece. Turn on the induction heating coil to heat the metal sample stage and the workpiece until the temperature displayed by the thermocouple reaches 165°C and keep the temperature constant.

[0072] 3. Laser cleaning the surface of the workpiece. Turn on the laser scanning system to clean the surface of the workpiece by nanosecond pulse laser sputtering, the energy density of the nanosecond pulse laser is 1000 mJ / cm 2 , the overlap rate is 30%, and then turn off the laser scanning system.

[0073] 4. Laser cladding. Open the valve, let the argon enter the nickel carbonyl source tank through the mass flow meter, load the carbonyl nickel into the vacuum chamber, adjust the flow rate of the argon, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com