Enhanced antistatic polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polypropylene composite material and its preparation, can solve problems such as limiting the application range of polypropylene, generating static electricity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

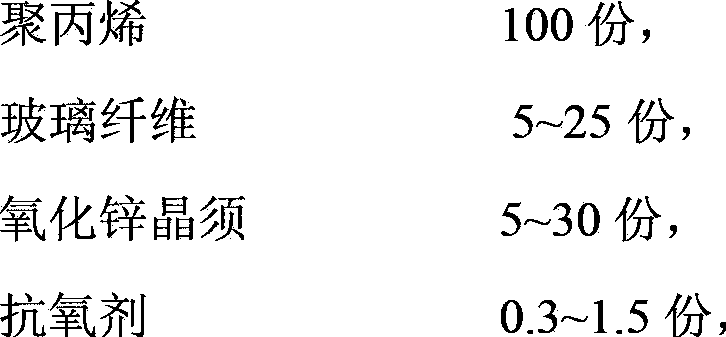

Method used

Image

Examples

Embodiment 1

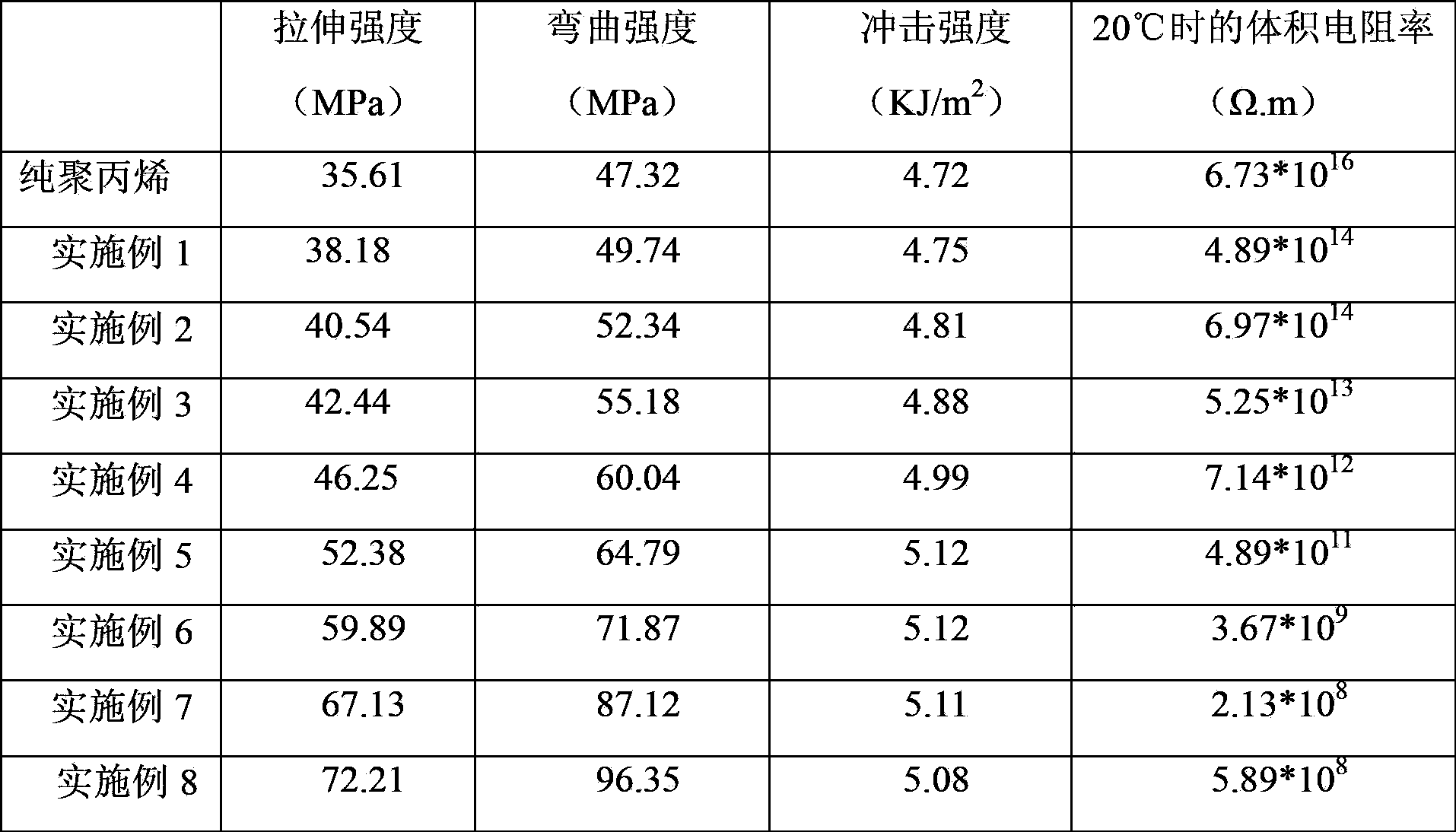

[0034] 100 parts of polypropylene, 5 parts of zinc oxide whiskers, 0.3 parts of antioxidant 2,6-tertiary butyl-4-methylphenol, 0.2 parts of lubricant stearic acid, 0.1 part of coupling agent 3-aminopropyl Triethoxysilane (KH550) and 0.1 part of calcium carbonate are mixed uniformly in a mixer, and 5 parts of alkali-free glass fiber yarn is added from the glass fiber inlet of the extruder, and then the blend is extruded with a twin-screw Machine mixing, extrusion temperature is 200~235℃, twin-screw extruder screw speed is 300r / min, after cooling and pelletizing, zinc oxide whisker and glass fiber reinforced antistatic polypropylene pellets are obtained. The properties are shown in the table 1.

Embodiment 2

[0036] 100 parts of polypropylene, 8 parts of zinc oxide whiskers, 0.5 parts of antioxidant diphenylamine, 0.3 parts of calcium stearate, 0.3 parts of coupling agent γ-(methacryloxy)propyltrimethoxysilane (KH570 ) and 0.2 parts of calcium silicate are mixed uniformly in the mixer, 8 parts of alkali-free glass fiber yarn is added from the glass fiber inlet of the extruder, and then the blend is mixed with a twin-screw extruder, and the extrusion temperature The temperature is 200~235°C, the screw speed of the twin-screw extruder is 315r / min, and after cooling and pelletizing, zinc oxide whisker and glass fiber reinforced antistatic polypropylene pellets are obtained. The properties are shown in Table 1.

Embodiment 3

[0038] 100 parts of polypropylene, 10 parts of zinc oxide whiskers, 0.7 parts of 3,5-tertiary butyl-4-hydroxyphenyl sulfide, 0.5 parts of zinc stearate, 0.3 parts of 3-aminopropyltriethoxy Silane (KH550) and 0.3 parts of dicyclohexyl terephthalylene were mixed uniformly in a mixer, and 10 parts of alkali-free glass fiber yarn was added from the glass fiber inlet of the extruder, and then the blend was extruded with a twin-screw Machine mixing, extrusion temperature is 200~235℃, twin-screw extruder screw speed is 325r / min, after cooling and pelletizing, zinc oxide whisker and glass fiber reinforced anti-static polypropylene pellets are obtained. The properties are shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com