A method for preparing zirconium boride powder with rod-like morphology

A zirconium boride and rod-shaped technology, applied in the field of powder preparation, can solve the problems of poor oxidation resistance of carbides and nitrides, limited application, etc., and achieve the effects of cheap raw materials, strong practicability and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Zirconia (99% purity, 0.3μm average particle size), boron carbide (96% purity, 1.5μm average particle size), graphite (99% purity, 1.5μm average particle size) as raw materials , based on borothermic / carbothermic reduction reaction, weighed 24.645g zirconia, 5.525g boron carbide, 3.6g graphite, using absolute ethanol as ball milling medium, Si 3 N 4 The ball is a grinding ball, and the ratio of ball to material is 2:1. After 24 hours of ball milling, the slurry is rotated and evaporated at 40°C to obtain a uniformly mixed powder; at 50kg / cm 2 The uniformly mixed powder is pressed into a green body under a certain pressure; heat treatment is carried out under an argon atmosphere: the heating rate is 10°C / min, the heat treatment temperature is 1600°C, and the temperature is kept for 2 hours.

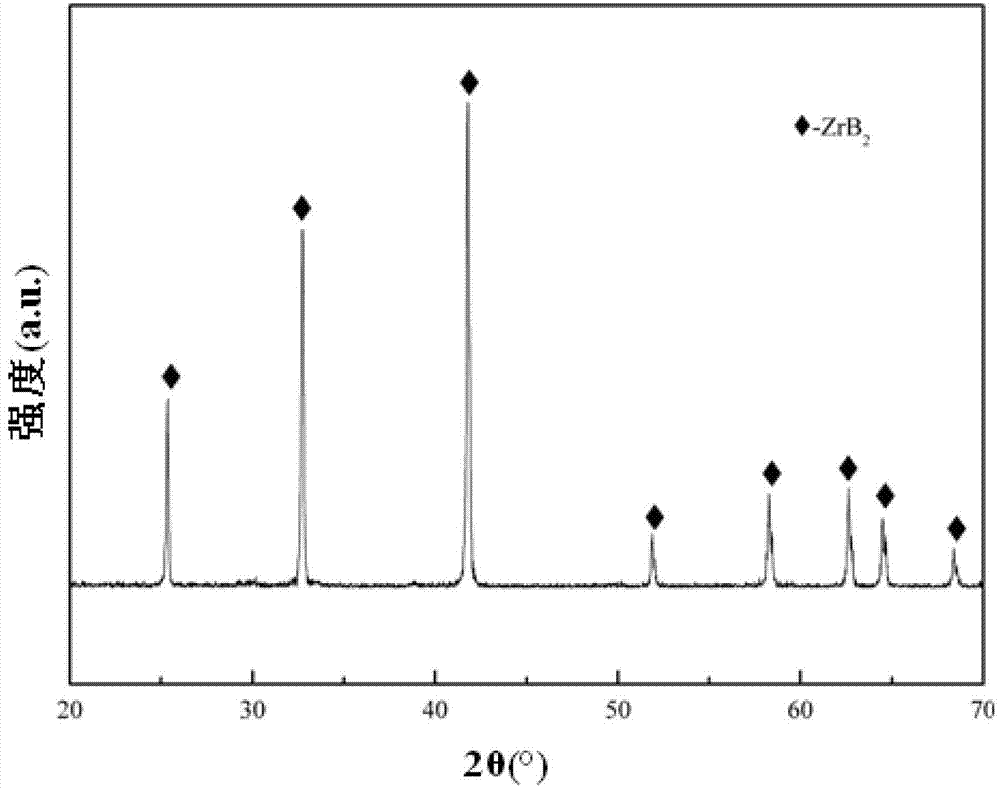

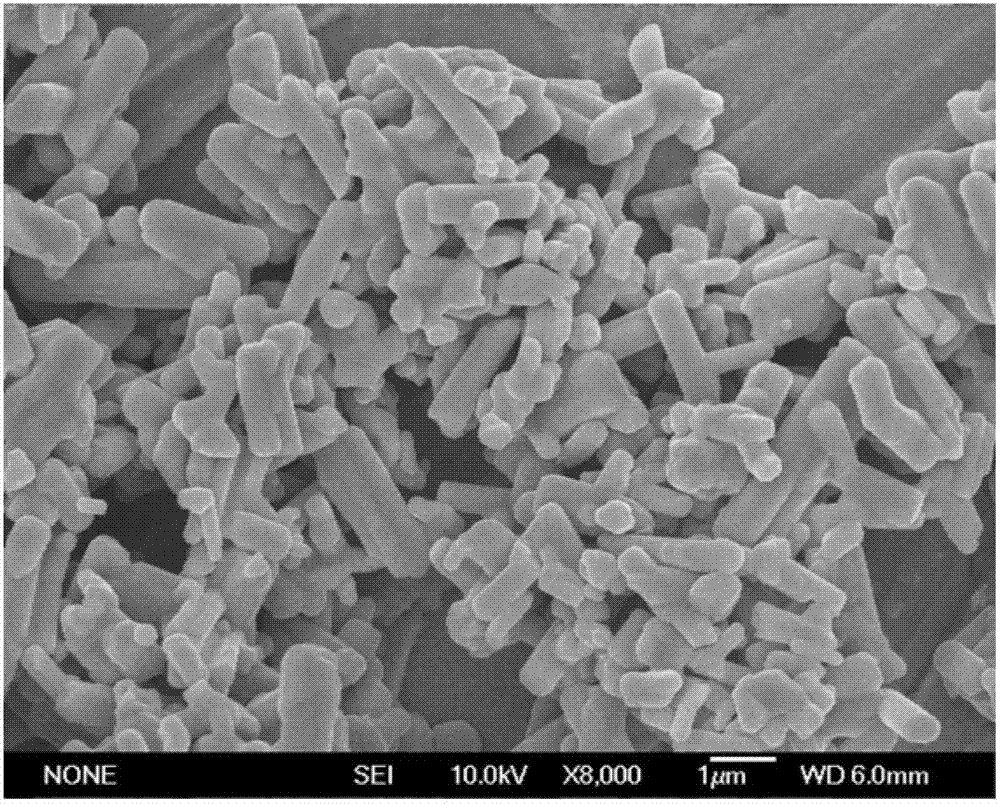

[0027] figure 1 For the XRD spectrum of the obtained zirconium boride powder, figure 2 For the SEM photo of the obtained zirconium boride powder, combined with figure 1 with ...

Embodiment 2

[0029] The difference between this example and Example 1 is that the formula of the mixed powder is "24.645g of zirconium dioxide, 2.763g of boron carbide, and 6g of graphite".

[0030] The rest of the content is exactly the same as described in Example 1.

[0031] After detection and analysis, it is known that the main component of the obtained powder is ZrB 2 , low oxygen content, the average particle size is 1.6 μm, the aspect ratio of rod-shaped particles is 3-7, and the content of rod-shaped particles is greater than 90wt%.

[0032] Comparing this example with Example 1 can further illustrate: under the same pressing pressure of the green body, the proportion of the mixed powder has little effect on the rod shape.

Embodiment 3

[0034] The formula of the mixed powder is "24.645g of zirconium dioxide, 8.288g of boron carbide, and 0.6g of graphite".

[0035] The rest of the content is exactly the same as described in Example 1.

[0036] After detection and analysis, it is known that the main component of the obtained powder is ZrB 2 , low oxygen content, the average particle size is 1.5 μm, the aspect ratio of rod-shaped particles is 3-7, and the content of rod-shaped particles is greater than 90wt%.

[0037] Comparing this example with Example 1 can further illustrate: under the same pressing pressure of the green body, the proportion of the mixed powder has little effect on the rod shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com