Composite magnet manufacturing method using neodymium iron boron magnetic sheets

A composite magnet, NdFeB technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of increasing production costs, increasing the amount of heavy rare earth elements, etc., to reduce the amount of use and meet the mechanical properties. requirements, the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

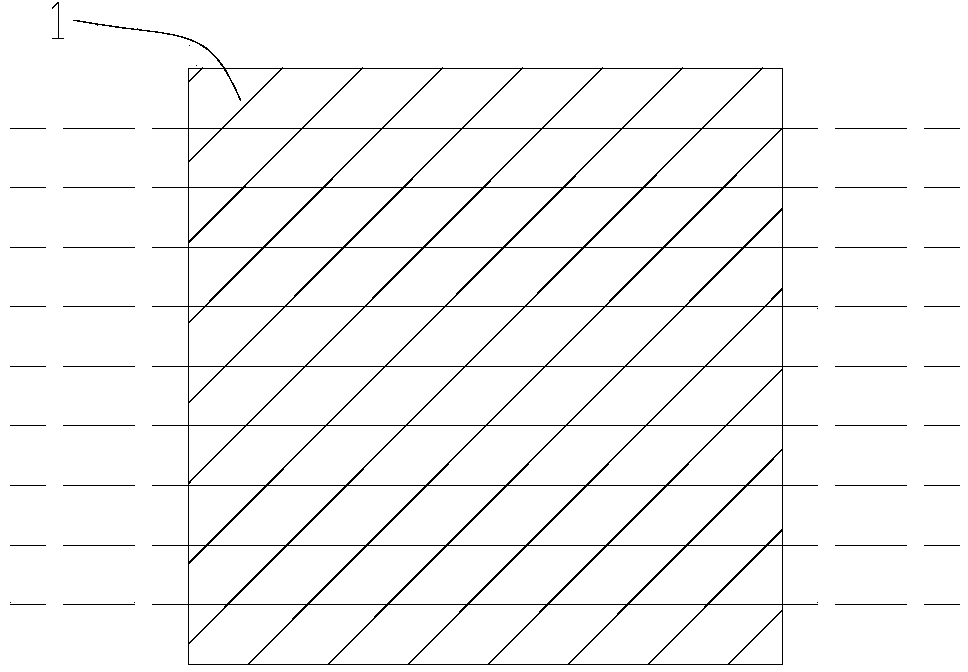

[0026] Refer to the attached figure 1 The method for manufacturing a composite magnet with NdFeB magnetic sheets of the present invention is illustrated.

[0027] 1) Prepare the magnetic sheet of the R-T-B series rare earth sintered magnet.

[0028] In the present invention, the preparation of the magnetic sheet does not limit the formula and sintering process of the R-T-B series rare earth sintered magnet, and the following is only a general description. The process includes: melting and casting-crushing-orientation forming-sintering-machining.

[0029] The corresponding raw materials are prepared in the formula of a certain R-T-B series rare earth sintered magnet. The raw materials are put into the smelting furnace and smelted into molten materials. The molten material is cast into a cast sheet with a specified average thickness, and the casting method can be strip casting or centrifugal casting. The casting sheet is crushed into alloy powder with a specified particle siz...

Embodiment 2

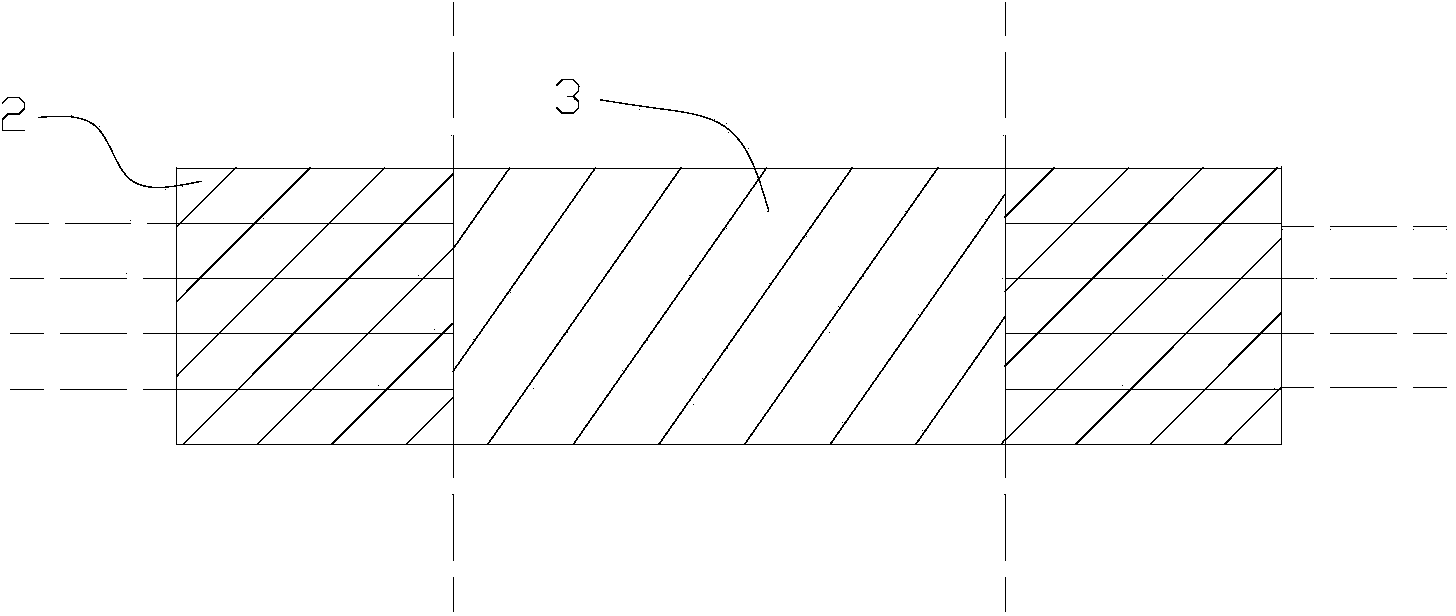

[0050] Prepare the thickness W by the aforementioned method 1 , brand 48H magnetic sheet (its Br is 14.08kGs, Hcj is 17.42kOe, (BH)max is 48.48MGOe), and the thickness is W 2 , Brand 42SH magnetic sheet (its Br is 12.72kGs, Hcj is 26.35kOe, (BH)max is 40.32MGOe), the goal is to manufacture a thickness of W 3 composite magnets. Refer to attached figure 2 As shown, the surface treatment of the magnetic sheet is carried out, and the steps are the same as those described in Embodiment 1, and will not be repeated here. At this time, the thickness of the magnetic sheet of grade 48H is reduced to W 1 ′, the thickness of the magnetic sheet of grade 42SH is reduced to W 2 '. According to the formula N 1 ×a 1 W 1 '=N 2 ×a 2 W 2 '≥W 3 (a 1 and a 2 is the coefficient of variation of the thickness of the magnetic sheet before and after bonding, mainly affected by the heat treatment temperature, usually in the range of 0.98 to 1.02), determine N 1 and N 2 value (rounded), t...

Embodiment 3

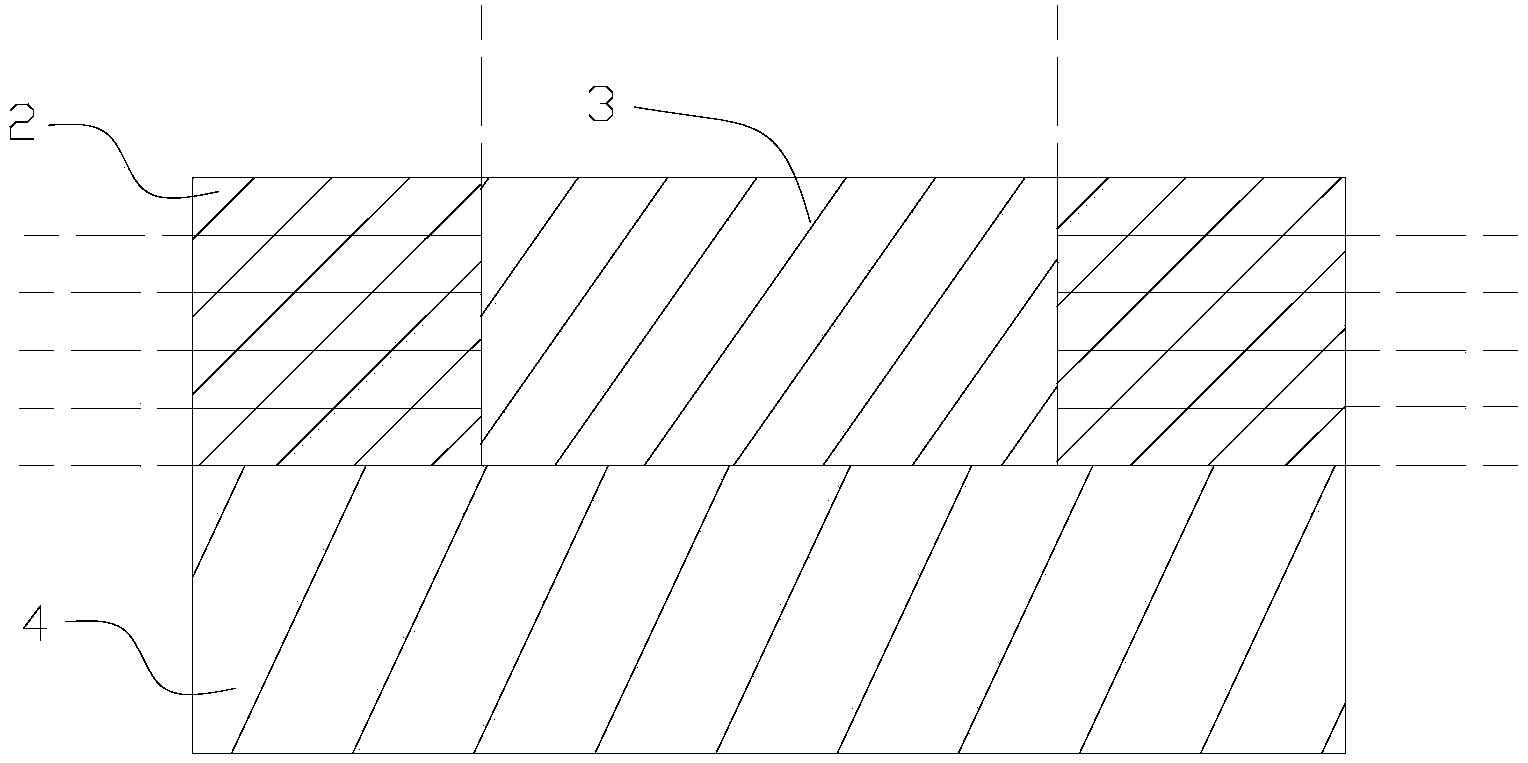

[0055] Prepare the magnetic sheet of brand 50N (its Br is 14.43kGs, Hcj is 12.26kOe, (BH)max is 49.12MGOe), the magnetic sheet of brand 48H (its Br is 14.08kGs, Hcj is 17.42kOe, (BH) max is 48.48MGOe) and the magnetic sheet of brand 42SH (its Br is 12.72kGs, Hcj is 26.35kOe, (BH)max is 40.32MGOe). The combination of the above-mentioned magnetic sheets is fixed under pressure and subjected to heat treatment, so that a thermocompression bonding process occurs between the magnetic sheets and finally combined into a composite magnet. Afterwards, the composite magnet is post-processed to meet the specified size requirements, and finally its performance is tested. Among them, it is assumed that the coefficient of variation of the thickness of the magnetic sheet is 1.0, and the specific scheme is:

[0056] Prepare 40.0mm (length) × 10.0mm (width) × 10.2mm (thickness), the brand is 50N magnetic sheet, 20.1mm (length) × 10.0mm (width) × 10.1mm (thickness), the brand is 48H Magnetic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com