Water-based release agent for aluminum alloy die casting and preparation method thereof

A mold release agent, aluminum alloy technology, used in casting molding equipment, metal processing equipment, casting molds, etc., can solve problems such as unfriendly people and the environment, achieve good film-forming effect, reduce emulsification difficulty, and excellent heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

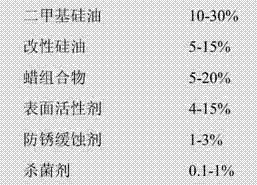

[0022] 1. Formula:

[0023]

[0024] The rest is deionized water

[0025] 2. Preparation method: 15kg of dimethyl silicone oil, 8kg of long-chain alkyl silicone oil, 5kg of paraffin wax, 5kg of microcrystalline wax, 4kg of fatty alcohol polyoxyethylene (5) ether, 1.5kg of fatty alcohol polyoxyethylene (25 ) ether and 1.5kg of alkylphenol polyoxyethylene (10) ether were heated and kept at 70°C, mixed and stirred well, and 30kg of deionized water was slowly added in batches and in small amounts under stirring to make O / W The pre-emulsion is passed through a colloid mill, and 1.5 kg of triethanolamine oleate, 0.3 kg of benzisothiazolone, and the remaining deionized water are added to make a water-based release agent with an emulsion particle size of about 0.1 μm.

Embodiment 2

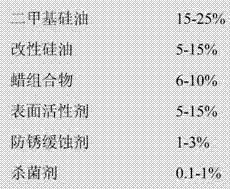

[0027] 1. Formula:

[0028]

[0029]

[0030] The rest is deionized water

[0031] 2. Preparation method: mix 10kg of dimethyl silicone oil, 15kg of long-chain alkyl silicone oil, 3kg of ozokerite wax, 3kg of microcrystalline wax, 5kg of fatty alcohol polyoxyethylene (7) ether, 5kg of fatty alcohol polyoxyethylene (20 ) ether and 5kg of isomeric tridecanol polyoxyethylene (9) ether were heated and kept at 80°C, mixed and stirred well, and 35kg of deionized water was slowly added in batches and in small amounts under stirring to make O / Take the pre-emulsion, pass it through a colloid mill, and add 1 kg of diethanolamine, 1 kg of isothiazolinone, and the remaining deionized water to make a water-based release agent with an emulsion particle size of about 0.3 μm.

Embodiment 3

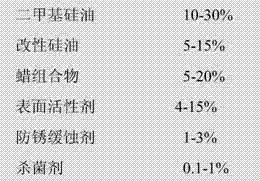

[0033] 1. Formula:

[0034]

[0035] The rest is deionized water

[0036] 2. Preparation method: mix 25kg simethicone oil, 6kg hydroxyhydrocarbyl silicone oil, 2kg ozokerite wax, 3kg microcrystalline wax, 2kg fatty alcohol polyoxyethylene (3) ether, 3kg sorbitan fatty acid ester and 1kg The isomeric tridecyl alcohol polyoxyethylene (6) ether is heated and kept at 75°C, mixed and stirred well, and 40kg of deionized water is slowly added in batches and a small amount under stirring to make an O / W pre-emulsion. Pass through a colloid mill, add 1.5 kg of benzotriazole, 0.3 kg of benzisothiazolone, and the remaining deionized water to make a water-based release agent with an emulsion particle size of about 0.2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com