Glass-lined anti-corrosion steel pipe producing and welding processes

An anti-corrosion steel pipe and a manufacturing process technology, applied in the field of steel pipe manufacturing, can solve the problems of poor anti-corrosion effect and short service life, and achieve the effects of smooth inner wall, small fluid resistance and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

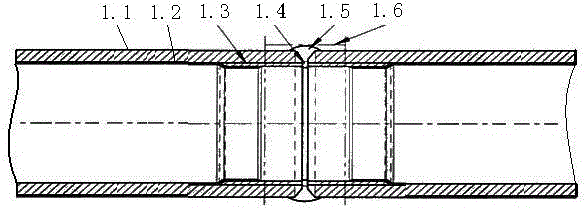

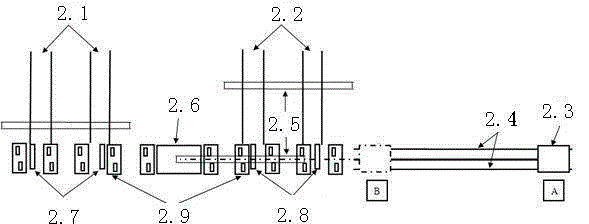

[0033] see figure 1 , firstly provide a manufacturing process of glass-lined anti-corrosion steel pipe, including the following steps:

[0034] (1) Use an automatic surfacing welding machine to pre-surfacing a nickel-based corrosion-resistant alloy layer 1.3 on the end face of the steel pipe 1.1 to a depth of 30-50 mm, with a thickness of 1.5-2 mm, and melt it on the base material to obtain a pipe The corrosion resistance of the surfacing layer;

[0035] (2) Bevel the end face of the steel pipe for surfacing pretreatment, and use an inner hole grinder to polish the surface of the nickel-based surfacing layer;

[0036] (3) The inner wall of the steel pipe is derusted by shot peening and derusting equipment on the inner wall of the steel pipe, which is required to meet the Sa2.5 level; the inner wall of the steel pipe after derusting is purged and dust-removed with dry and clean compressed air, and no steel sand and steel shots are required. , no ups and downs;

[0037] (4) T...

Embodiment 2

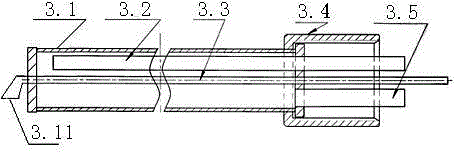

[0043] see Figure 1-3 , on the basis of Example 1, keep other steps and device structure unchanged, only change steps (1) and (2) to the following steps respectively:

[0044] (1) Welded stainless steel joints at both ends of the steel pipe: use 304 and above grade stainless steel pipe pre-processed joints with the same outer diameter and wall thickness as the processed steel pipe with good corrosion resistance (the length of the short joint conforms to GB50235-2010 "Industrial Metal Pipeline Construction "Specification" requirements); use friction welding or manual arc welding to weld the stainless steel joints to both ends of the steel pipe.

[0045] (2) Clean and polish the weld seam of the steel pipe welded with stainless steel joints, and the weld seam of the inner hole is required to be smooth.

Embodiment 3

[0047] The glass-lined anticorrosion steel pipes made in Examples 1 and 2 are welded in the following manner:

[0048] During butt welding construction of the on-site pipeline group, the double-sided shielded welding of the nickel-based stainless steel wire tungsten argon arc welding corresponding to the nickel-based corrosion-resistant alloy layer 1.3 (the nickel-based corrosion-resistant layer 1.4), and then filled with nickel-based stainless steel welding wire (nickel-based stainless steel welding wire is preferably AWS A5.14 ERNiCrMo-3) or an electrode with corresponding corrosion resistance (forming filling layer 1.5), so that the nickel-based surfacing layer and The base metal and the solder form a metallurgical combination to ensure the welding quality, and at the same time, a continuous layer of nickel-based alloy anti-corrosion protection layer is formed on the surface of the inner hole of the weld, which solves the problem of anti-corrosion on the inner surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com