Preparation method and device for polyenoic acid and ester monomer thereof

A technology of polyenoic acid and monomer, which is applied in the field of preparation of polyenoic acid and its ester monomer, can solve problems such as uncoupled green pretreatment process, achieve efficient preparation, avoid pollution, and reduce pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

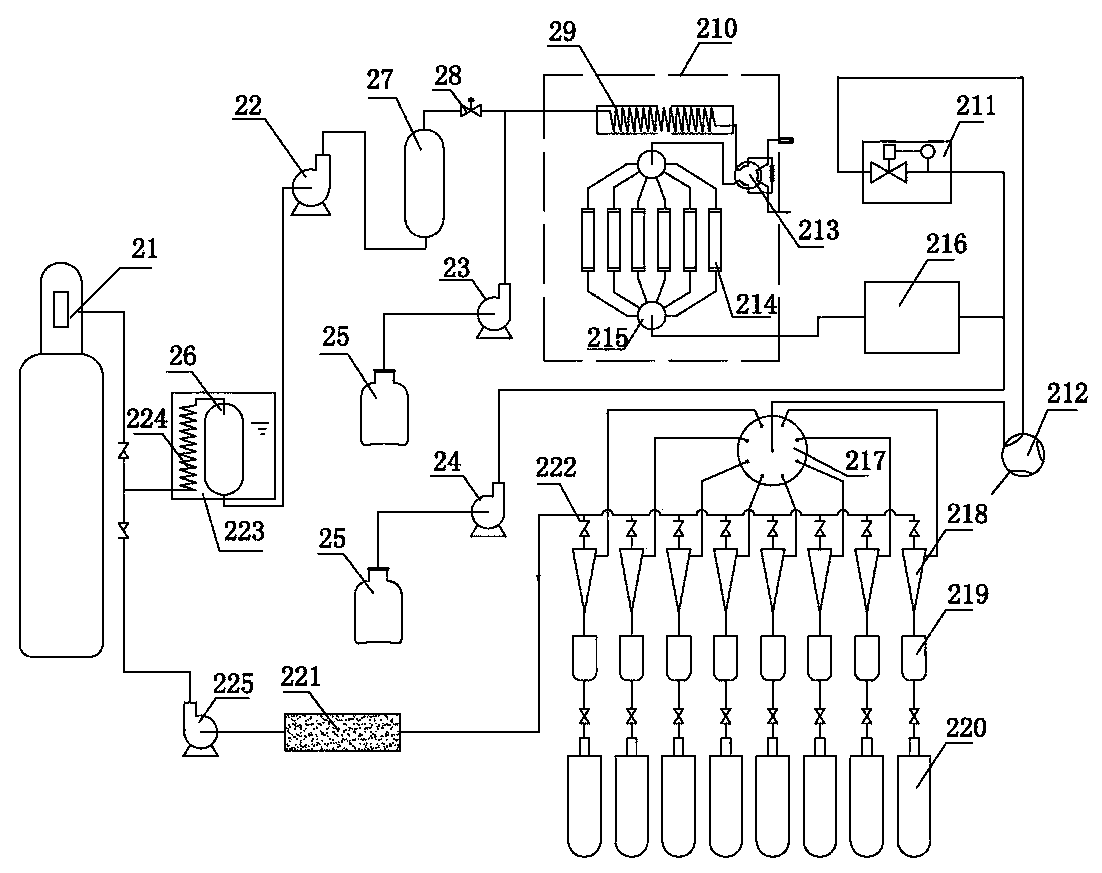

[0047] A kind of preparation method and device thereof of polyenoic acid and its ester monomer described in the present invention, such as figure 1 , 2 as shown,

[0048] It includes short path distillation separation and supercritical carbon dioxide fluid chromatography separation.

[0049] 1. Separation by short path distillation

[0050] The short path distillation device of the present invention is as figure 1 As shown, the short-distance distillation experimental device system consists of a feed tank 11, a control valve 12, a motor 13, a film scraper 14, an internal cooling hydrazine 15, a distillation kettle 16, a heat transfer oil inlet 17, a cold hydrazine 18, a vacuum pump 19, and a collection bottle 110 , cold water inlet 111, cold water outlet 112, light phase collection valve 113, heavy phase collection valve 114, heat transfer oil outlet 115. The working principle of the short-path distillation system has been described in detail in many documents and works, and...

Embodiment 1

[0079] After ethyl esterification, the arachidonic acid crude oil is put into the short-path distillation feed tank, the vacuum pump and temperature controller are turned on, and the degassing, solvent removal, moisture and volatile components are carried out at a vacuum degree of 20Pa and a temperature of 90°C. 1 hour. Turn on the short-path distillation feed pump, set the heating temperature to 95°C and the condensation temperature to 10°C, and conduct short-path distillation under the condition of 0.1-0.15Pa, and receive the light phase components from the condensation end. The received light phase components are dissolved into a solution with a certain concentration with a solvent, and the supercritical carbon dioxide fluid is used to prepare a chromatographic device for separation and preparation.

[0080] Two high-purity silica gel chromatographic columns (diameter 10 mm, length 250 mm, packing particle size 5 μ) were used; the temperature of the cryostat was -10 ° C; th...

Embodiment 2

[0084] Put the arachidonic acid crude oil after methylation into the short-path distillation feed tank, turn on the vacuum pump and temperature controller, and carry out degassing, solvent, moisture and volatile components at a vacuum degree of 20Pa and a temperature of 80°C. 1 hour. Turn on the short-path distillation feed pump, set the heating temperature to 85°C, and the condensation temperature to 8°C, conduct short-path distillation under the condition of 0.1-0.15Pa, and receive the light phase components from the condensation end. The received light phase components are dissolved into a solution with a certain concentration with a solvent, and the supercritical carbon dioxide fluid is used to prepare a chromatographic device for separation and preparation.

[0085] One high-purity silica gel chromatographic column (diameter 20 mm, length 250 mm, packing particle size 5 μ) is used; the temperature of the cryostat is -5 ° C; the system back pressure is 9-14 MPa; the column...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com