A silk fibroin gel microneedle system and preparation method thereof

A silk fibroin and gel technology, which is applied to a microneedle system composed of a silk fibroin solidified product and its preparation field, can solve problems such as loss of drug activity, and achieve the effects of simple method and mild processing conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

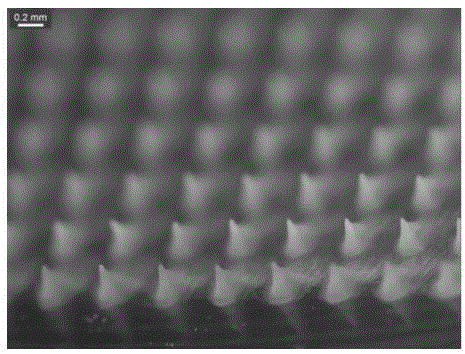

Embodiment 1

[0020] (1) Mold production: select a PDMS film with a thickness of about 2mm, and set the laser conditions as follows: a carbon dioxide laser with a power of 30 watts, a focusing aperture of 100 μm, a carbon dioxide laser power of 5W, a frequency of 3000, and a dotting time of 5ms. Square array, each hole is 500 μm apart, the mold made under this laser drilling condition, the microneedle length is 450 μm, and the diameter of the base is about 250 μm.

[0021] (2) Preparation of silk fibroin solution: Take 80g of silkworm raw silk and put it into 5000ml of 0.06% sodium carbonate solution, boil it three times at 98-100°C, use deionized water for three times, and treat each time for 30min to remove the raw silk The sericin in the fiber is washed, loosened and then dried in an oven at 60°C to obtain pure silk fiber. Dissolve the dried silk fiber in 9.3M lithium bromide solution at 65°C, the bath ratio is 3:20, and the dissolution time is about 1 hour. After it cools down, take it ...

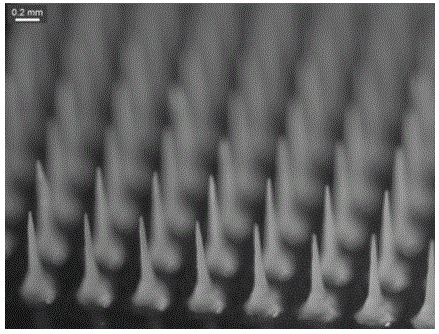

Embodiment 2

[0024] (1) Mold production: select a PDMS film with a thickness of about 1.5mm, set the laser conditions as follows: 30W carbon dioxide laser, focusing aperture 200μm, power 15W, frequency 6000, dotting time 10ms, punch out 10*10 hole square array Array, each hole is separated by 500 μm, the mold made under this laser drilling condition has a micro-length of 700 μm and a base diameter of about 250 μm.

[0025] (2) Preparation of silk fibroin solution: Take 80g of silkworm raw silk and put it into 5000ml of 0.05% sodium carbonate solution, boil it three times at 98-100°C, use deionized water for three times, and treat each time for 30min to remove the raw silk The sericin in the fiber is washed, loosened and then dried in an oven at 60°C to obtain pure silk fiber. Dissolve the dried silk fiber in 9.3M lithium bromide solution at 65°C, the bath ratio is 3:20, and the dissolution time is about 1 hour. After it cools down, take it out and put it into a dialysis bag and place it in...

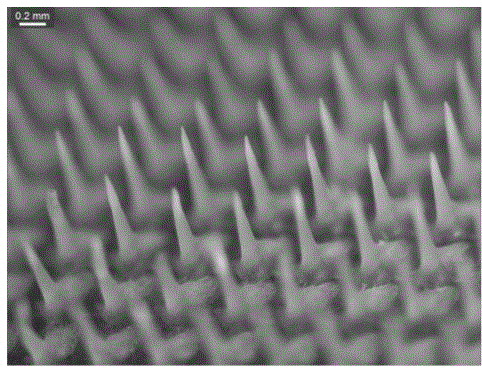

Embodiment 3

[0028] (1) Mold production: Select a PDMS film with a thickness of about 2mm, set the laser conditions as follows: carbon dioxide laser, focusing aperture 300μm, power 27W, frequency 9000, dotting time 20ms, punch out a square array of 15*15 holes, each hole With a distance of 600 μm, the mold made under this laser drilling condition has a microneedle of 1000 μm and a base diameter of about 250 μm.

[0029](2) Preparation of silk fibroin solution: Preparation of silk fibroin solution: Take 80g of silkworm raw silk and put it into 5000ml of sodium carbonate solution with a concentration of 0.06%. After processing for 30 minutes, the sericin in the raw silk is removed, washed, loosened, and dried in an oven at 60°C to obtain pure silk fiber. Dissolve the dried silk fiber in 9.3M lithium bromide solution at 65°C, the bath ratio is 3:20, and the dissolution time is about 1 hour. After it cools down, take it out and put it into a dialysis bag and place it in deionized water for dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com