Method for dissolving natural cellulose

A natural cellulose and solution technology, applied in the field of natural polymers, can solve the problems of low reactivity of cellulose, long dissolution time, complex conditions, etc., and achieve the effects of good stability, strong operability and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

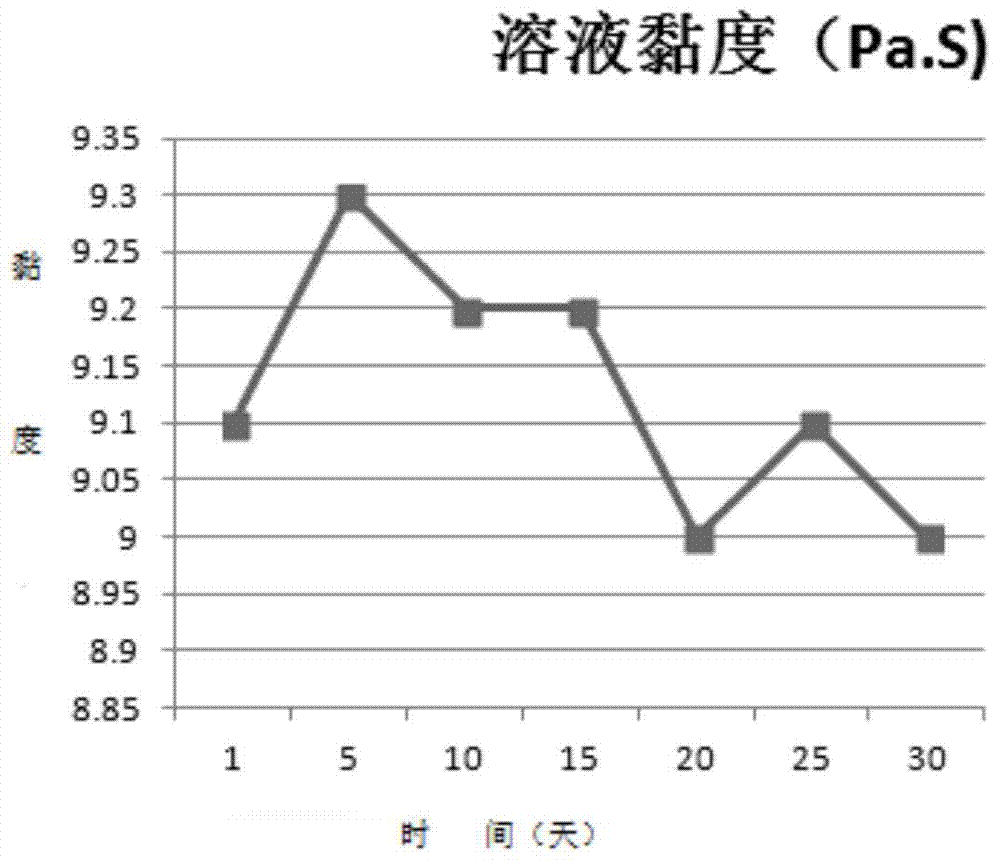

Image

Examples

Embodiment 1

[0029] (1) Cut 5g of natural cotton fibers into pieces, put them into 200mL of NaOH solution with a mass concentration of 17%, activate them with ultrasonic wave at room temperature for 60min, wash the cotton fibers with deionized water until neutral; Cotton fibers were first immersed in 50mL of dimethylacetamide (DMAC) for 45 minutes; then immersed in 50mL of anhydrous methanol for 45 minutes, and finally dried in an electric blast drying oven;

[0030] (2) Dry LiCl in a vacuum oven at 150°C for 18 hours. Under the protection of nitrogen, take dry 10g LiCl and add it to 100mL of DMAC, stir and dissolve, heat up to 100°C, add to step (1) and dry Keep the temperature of 100°C, stir for 120min, and the stirring speed is 500rpm / min; drop to room temperature and continue stirring, the stirring speed is still 500rpm / min, stirring and dissolving for 4 hours, ultrasonic vibration and defoaming of the solution for 60min, to obtain Uniform and transparent spinning solution, the mass fr...

Embodiment 2

[0033] (1) Cut 3 g of natural cotton fibers into pieces, put them into 200 mL of NaOH solution with a mass concentration of 17%, activate them with ultrasonic waves at room temperature for 50 minutes, and wash the cotton fibers to neutral with deionized water; Cotton fibers were first immersed in 50mL of dimethylacetamide (DMAC) for 40 minutes; then immersed in 50mL of anhydrous methanol for 40 minutes, and finally dried in an electric blast drying oven;

[0034] (2) Dry LiCl in a vacuum oven at 150°C for 18 hours. Under the protection of nitrogen, take dry 10g LiCl and add it to 100mL of DMAC, stir and dissolve, raise the temperature to 100°C, add to step (1) and dry Keep the temperature of 100°C, stir for 120min, and the stirring speed is 450rpm / min; drop to room temperature and continue stirring, the stirring speed is still 450rpm / min, stirring and dissolving for 4 hours, ultrasonic vibration and defoaming of the solution for 60min, to obtain Uniform and transparent spinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com