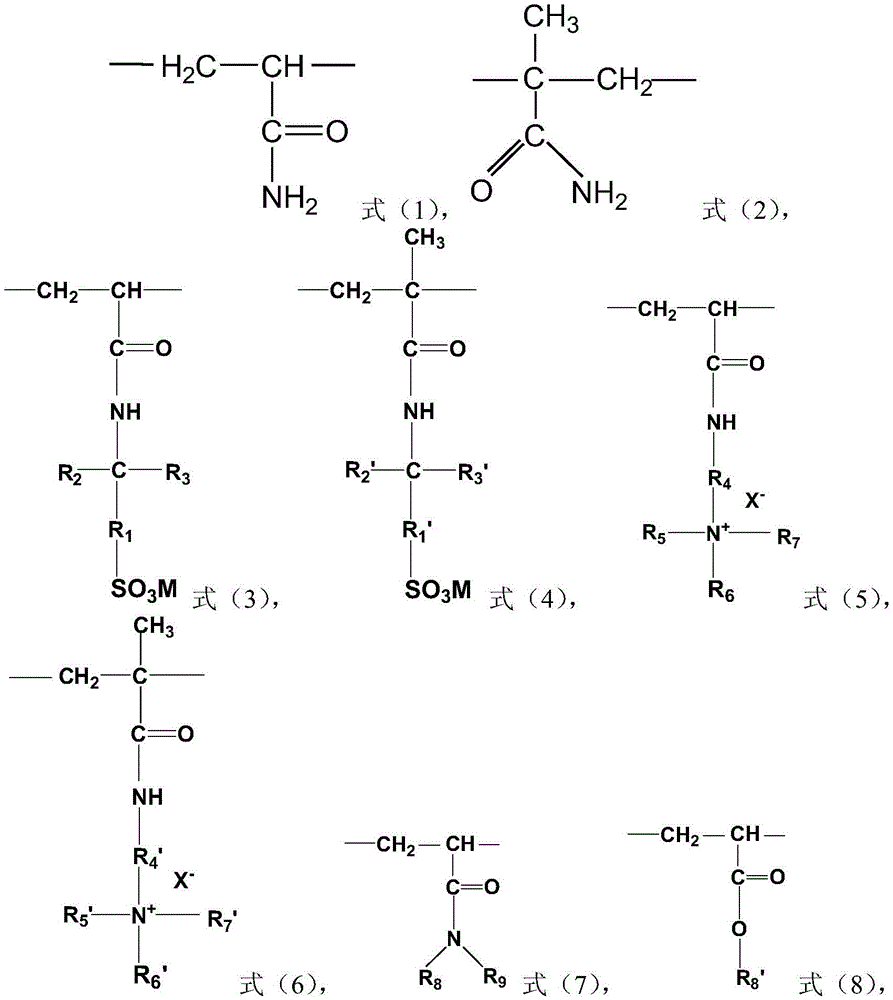

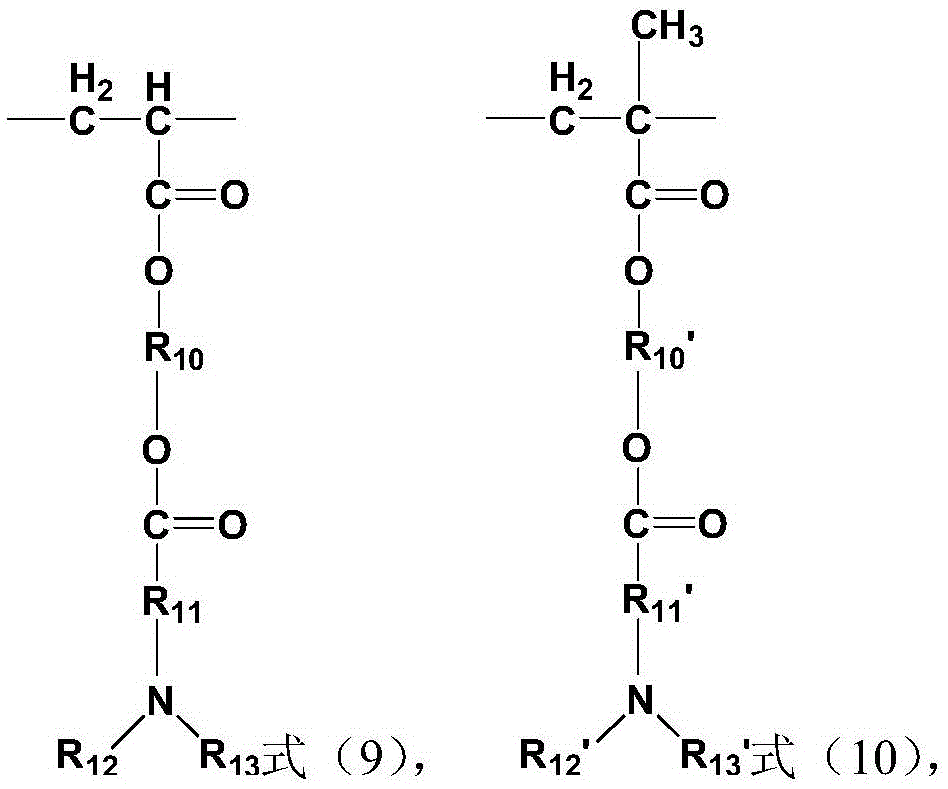

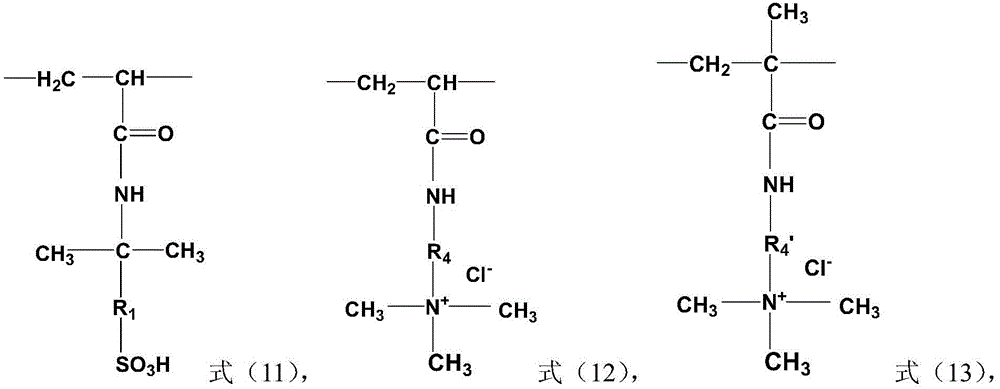

A kind of acrylamide series copolymer and its preparation method and application

An acrylamide-based, copolymer technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor fluid loss resistance, insignificant water-sensitivity effect, limited resistance-reducing performance, etc. Capacitive, simple monomer conversion, high drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] This example is used to illustrate the preparation of acrylamide copolymer by the solution polymerization method provided by the present invention.

[0085] At room temperature, 38.38g of acrylamide (AM), 39.65g of M1 monomer represented by formula (37), 4.03g of N,N-dimethylacrylamide (purchased from Sigma-Aldrich Company) and 0.41g The M2 monomer represented by the formula (38) (obtained according to the method of document Macromolecular Bioscience, 2006, 6(7), 540-554, the same below) was added into the reaction flask, 329.88g of deionized water was added, and stirred to make the single The body is completely dissolved and stirred evenly. 5.4 g of 1% by weight aqueous EDTA solution, 2.0 g of 1% by weight azobisisobutylamidine hydrochloride aqueous solution, and 0.12 g of urea were respectively added to the flask, and stirred well to make them uniform. Use 1% by weight of sodium hydroxide solution to pH 7.4, add 1.1 g of 0.5% by weight of sodium bisulfite solution, c...

Embodiment 2

[0094] This example is used to illustrate the preparation of acrylamide copolymer by the solution polymerization method provided by the present invention.

[0095] At room temperature, 35.23g of methacrylamide, 72.1g of M3 monomer shown in formula (40), 10.25g of tert-butyl acrylate and 0.01g of M2 monomer shown in formula (38) were added to the polymerization In the bottle, add 218.38g of deionized water, stir to dissolve the monomer completely, add 7.56g of 1% by weight of EDTA aqueous solution to the flask, add 2.13g of 1% by weight of azobisisobutylamidine hydrochloride aqueous solution, add Add 0.20 g of urea to 3.2 g of 0.1% by weight sodium bisulfite solution, and stir well to make it evenly mixed. The initial temperature of the system was controlled to 8°C, and after 30 minutes of deoxygenation with nitrogen, 1.0 g of 1% ammonium persulfate aqueous solution was added and nitrogen deoxygenation was continued for 10 minutes. Seal the reactor and keep it at 8°C. After re...

Embodiment 3

[0099] This example is used to illustrate the preparation of acrylamide copolymer by the solution polymerization method provided by the present invention.

[0100] At room temperature, 14.38g of methacrylamide, 11.61g of M4 monomer shown in formula (42), 7.12g of N-tert-butylacrylamide and 0.06g of M2 monomer shown in formula (38) Add it into the reaction bottle, add 77.26g of deionized water, stir to dissolve the monomer completely, and stir evenly. 4.65 g of 1% by weight aqueous EDTA solution, 1.03 g of 1% by weight azobisisobutylamidine hydrochloride aqueous solution, and 0.21 g of urea were respectively added to the flask, and stirred well to make them evenly mixed. The pH was adjusted to 7.1 with solid sodium hydroxide. Add 1.1 g of 0.5% by weight sodium bisulfite solution, control the initial temperature of the system to 10° C., and add 1.1 g of 1% by weight ammonium persulfate aqueous solution after nitrogen deoxygenation for 30 minutes, and continue nitrogen deoxygena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com