Preparation method of para aminoacet anilide

The technology of aminoacetanilide and nitroacetanilide is applied in the field of preparation of p-aminoacetanilide, can solve the problems of complicated preparation method, low product purity and high production cost, and achieves easy industrial production, high reduction yield and high production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

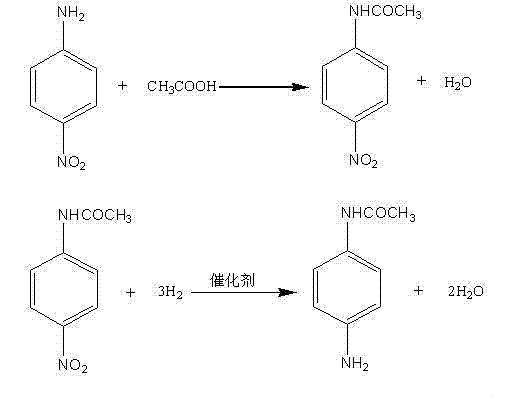

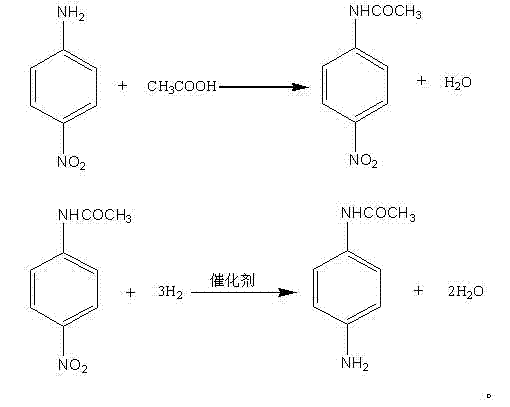

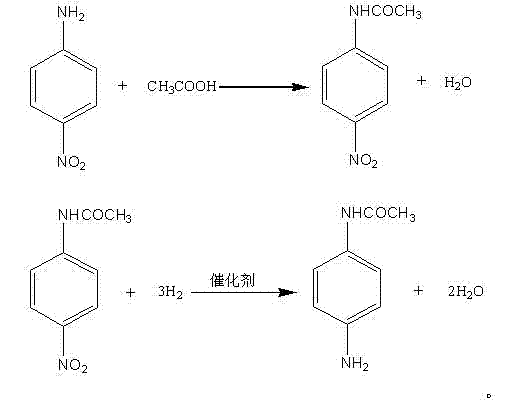

[0025] A preparation method of p-aminoacetanilide, the preparation steps are as follows:

[0026] ① Add p-nitroaniline and glacial acetic acid into the reaction kettle, mix well to obtain a mixed solution, the molar ratio of p-nitroaniline and glacial acetic acid is 1:4-8;

[0027] ②Heat the mixed solution in step ① to 120-130°C, and conduct heat preservation and distillation under normal pressure reflux for 18-20 hours to obtain the reaction solution;

[0028] ③After step ②, the reaction solution is completely dissolved and cooled, filtered, washed, and dried to obtain p-nitroacetanilide, and the obtained acetic acid filtrate is dehydrated and reused;

[0029] ④Put p-nitroacetanilide, catalyst and organic solvent into the autoclave, replace with nitrogen and hydrogen respectively, stir and heat up to 40-100°C, then fill with hydrogen to 0.5-1.5MPa, keep pressure and keep warm for 0.5-2 hours, to obtain p-aminoacetanilide solution, the mass ratio of p-nitroacetanilide to orga...

Embodiment 1

[0037] Embodiment 1, concrete steps are:

[0038] ①Add 36kg of p-nitroaniline and 78.5kg of glacial acetic acid into the reaction kettle, and stir evenly to obtain a mixed solution;

[0039] ②Heating the mixed solution to 120°C, under normal pressure and reflux for heat preservation and distillation for 20 hours to obtain the reaction solution;

[0040] 3. After the reaction solution is completely reacted, cool down, filter, wash, and dry to obtain 46 kg of p-nitroacetanilide, and reuse the obtained acetic acid filtrate after dehydration;

[0041] ④Add 5kg of palladium carbon, 276kg of methanol and 46kg of p-nitroacetanilide into the autoclave, close the autoclave, then replace it with nitrogen 3 times and hydrogen 3 times, stir and heat up to 60°C, then fill with hydrogen, the pressure of hydrogen is 1MPa , pressurized and heat-preserved for 1 hour to obtain p-aminoacetanilide solution;

[0042] ⑤ Filter the p-aminoacetanilide solution at 50°C, distill methanol, and after c...

Embodiment 2

[0044] Embodiment 2, concrete steps are:

[0045] ①Add 36kg of p-nitroaniline and 63kg of glacial acetic acid into the reaction kettle, and stir evenly to obtain a mixed solution;

[0046] ②Heating the mixed solution to 130°C, under normal pressure and reflux for heat preservation and distillation for 18 hours to obtain the reaction solution;

[0047] 3. After the reaction solution is completely reacted, the temperature is lowered, filtered, washed, and dried to obtain 44 kg of p-nitroacetanilide, and the obtained acetic acid filtrate is dehydrated and reused;

[0048] ④Add 6kg of Raney nickel, 230kg of isopropanol and 44kg of p-nitroacetanilide into the autoclave, close the autoclave, then replace with nitrogen 3 times, hydrogen 3 times, stir and heat up to 40°C, then fill with hydrogen, hydrogen The pressure is 0.5MPa, and the pressure-holding and heat-insulating reaction is carried out for 0.5 hours to obtain p-aminoacetanilide solution;

[0049] ⑤ Filter the p-aminoaceta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com